Fiber composite carbon aerogel material and preparation method thereof

A technology of fiber composite and carbon aerogel, which is applied in the preparation of high temperature resistant aerogel composite materials by using inorganic fiber materials composited with carbon aerogel, and in the field of airgel composite material preparation, which can solve the problem of inability to prepare 1000°C resistant The above high-temperature airgel insulation composite materials and other problems can achieve good mechanical strength and process performance, good high temperature resistance, and good formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] (II) Preparation of fiber composite phenolic gel: use the phenolic solution to impregnate inorganic fiber material and heat to obtain fiber composite phenolic gel;

[0062] (III) Aging of the fiber-composite phenolic gel: soaking the fiber-composite phenolic gel in an organic solvent for aging.

[0063] The organic solvent used in step (III) can be selected from the organic solvent commonly used in gel aging, especially carbon airgel aging, for example, it can be selected from ethanol, propanol, acetone, methyl ethyl ketone, cyclohexane, tetrahydrofuran, One or a combination of two or more of the group consisting of isopropyl ether and toluene, preferably acetone.

[0064] (IV) Supercritical fluid drying: performing supercritical fluid drying on the aged fiber-composite phenolic gel to obtain a fiber-composite phenolic airgel material; and

[0065] (V) Reaction in an atmosphere cracking furnace: the fiber composite phenolic airgel material is reacted in an atmosphere c...

Embodiment 1

[0080] Prepare phenolic solution according to the following raw materials and ratios: Dissolve resorcinol, formaldehyde and sodium carbonate in deionized water according to the following mass ratio: sodium carbonate: resorcinol: formaldehyde: water=1:55:85:1000, stir After uniformity, the phenolic solution was obtained.

[0081] Add the phenolic solution to the container with a bulk density of 0.5g / cm 3 In the mold of the zirconia fiber cotton, the phenolic solution is completely immersed in the inorganic fiber material and mixed evenly, wherein the addition of the inorganic fiber material is to make the carbon element in the carbon airgel and the mass ratio of the inorganic fiber material (Table 1 (abbreviated as "carbon to fiber ratio") is 1:60 (in this paper, the carbon element in the carbon airgel is calculated as follows: in the determined phenol and aldehyde substances, the carbon element is calculated according to their molecular structure respectively. The element per...

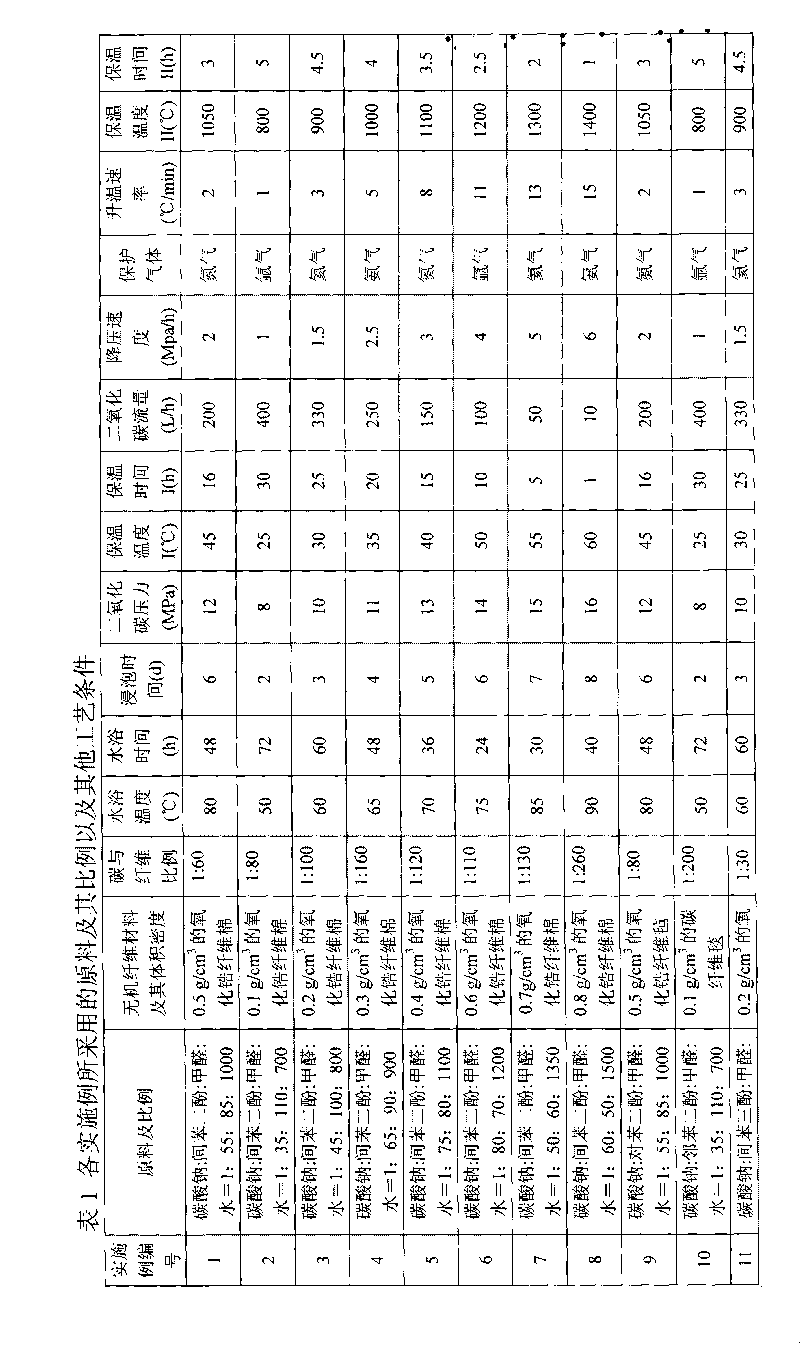

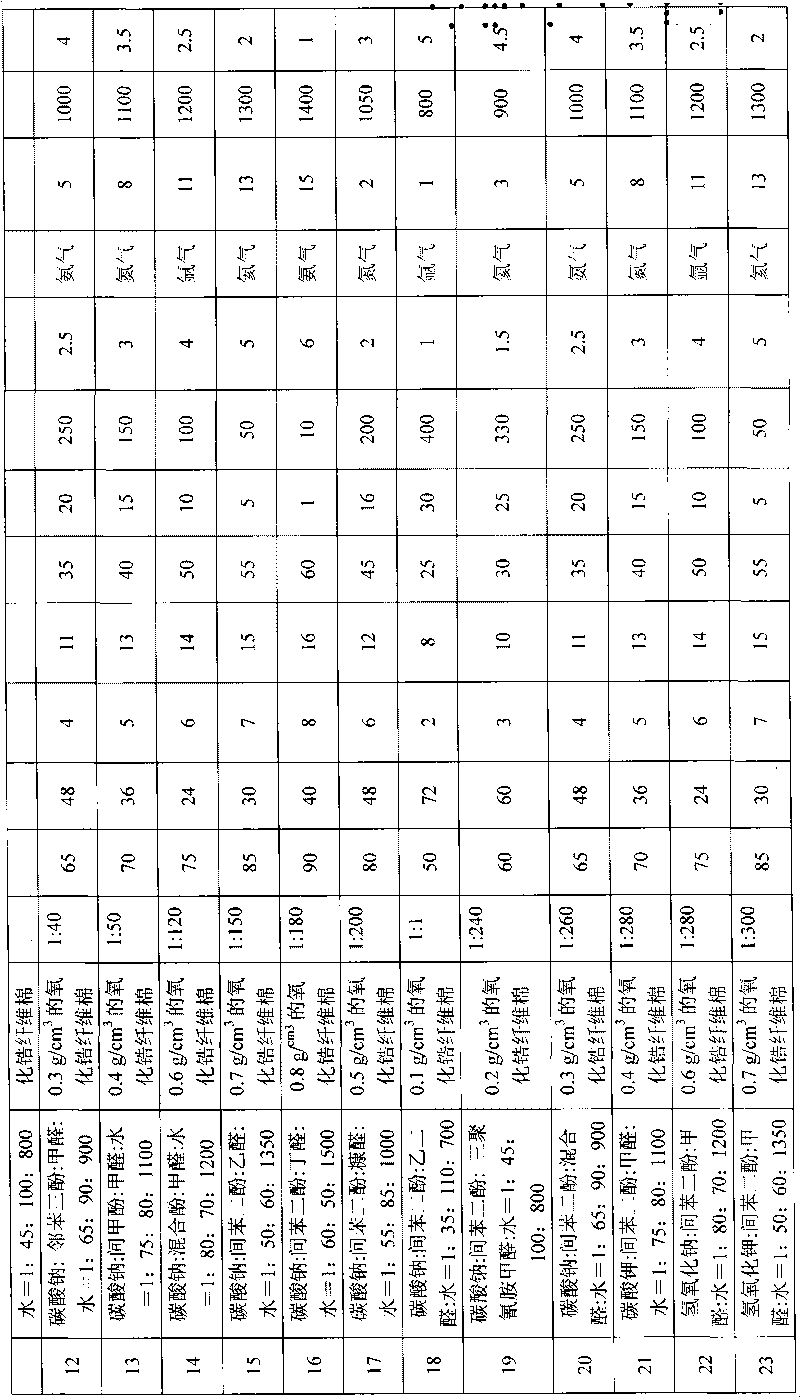

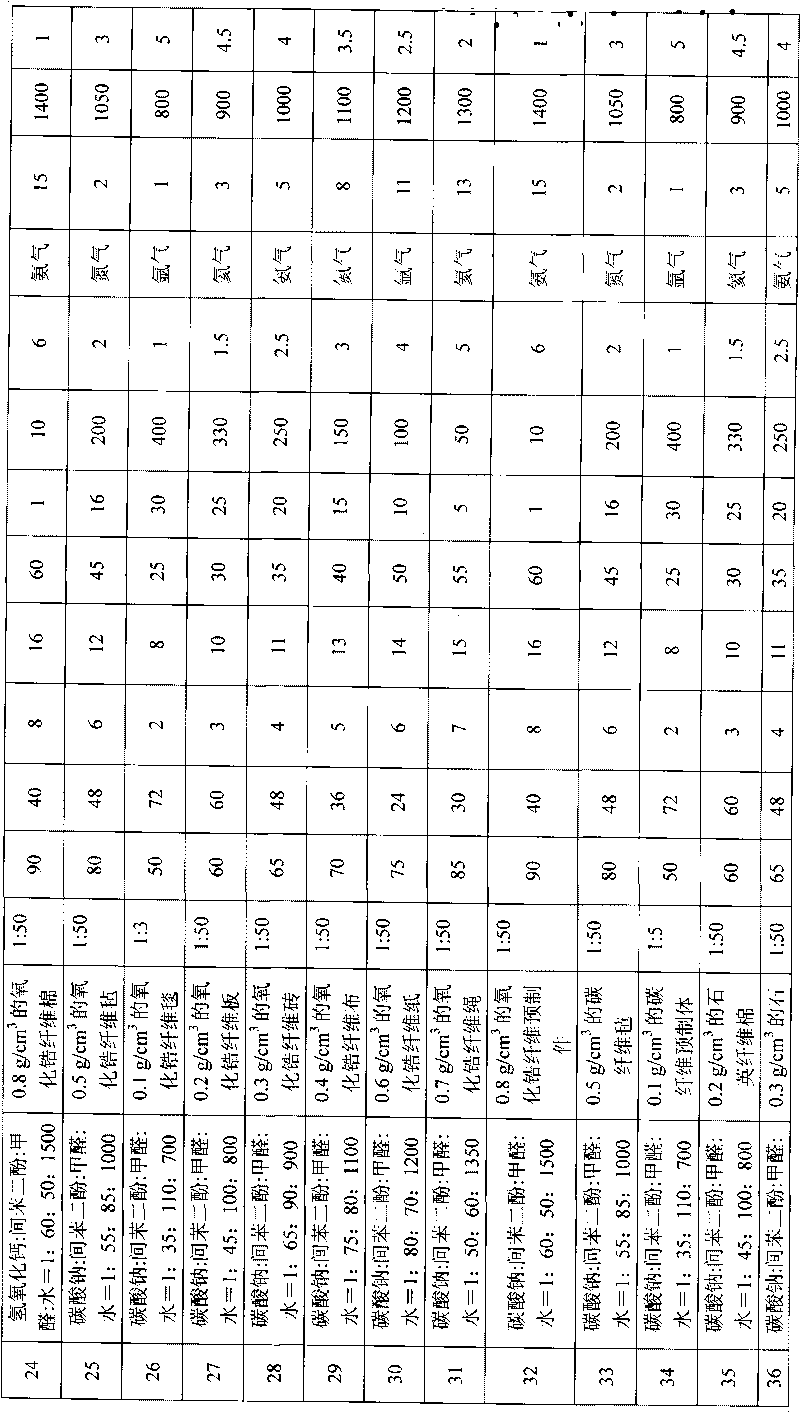

Embodiment 2 to 13、 Embodiment 15 to 19 and Embodiment 21 to 48

[0085] Except for the contents shown in Table 1 and the appended notes in Table 1, the others were carried out in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com