Nano high-molecular microsphere with conductivity and magnetism and its preparation method

A technology of nano-polymers and nano-microspheres, which is applied in the field of magnetic polymer nano-spheres and its preparation, and can solve the problems of large particle size, non-conductivity and nano-effects of magnetic polymer microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the magnetic fluid is as follows: a stirrer, a reflux condenser, a N 2 Add 20-100g polyethylene glycol (Mw=4000), 60ml FeSO 4 Solution (concentration 5~10%), 15~50mlH 2 o 2 solution (concentration 1-5%), adjust the pH value to about 13 with 3M NaOH solution, react at 50-70° C. for 5-10 hours, and then dialyze repeatedly in the magnetic field to neutrality, and set aside.

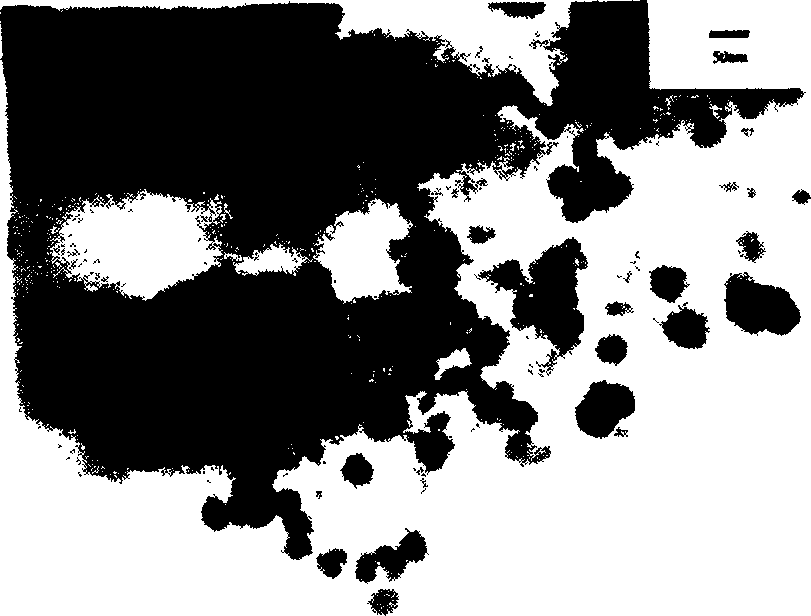

[0023] After the ferrofluid is prepared, it is equipped with a stirrer, reflux condenser, N 2 Add 1.0g of magnetic fluid, 15.0g of aniline, 50.0g of ethanol and 40.0g of deionized water into a 250ml four-neck bottle with a through tube, stir at 300r / min, pass through N 2 . After 30 minutes, add 0.45 g of ammonium persulfate and react at 0°C for 10 to 12 hours. The obtained microspheres are magnetically separated, washed and soaked in 1M HCl to remove uncoated or incompletely coated magnetic fluids to obtain magnetic polymer nanometer microspheres.

[0024] Add 1.5g of d...

Embodiment 2

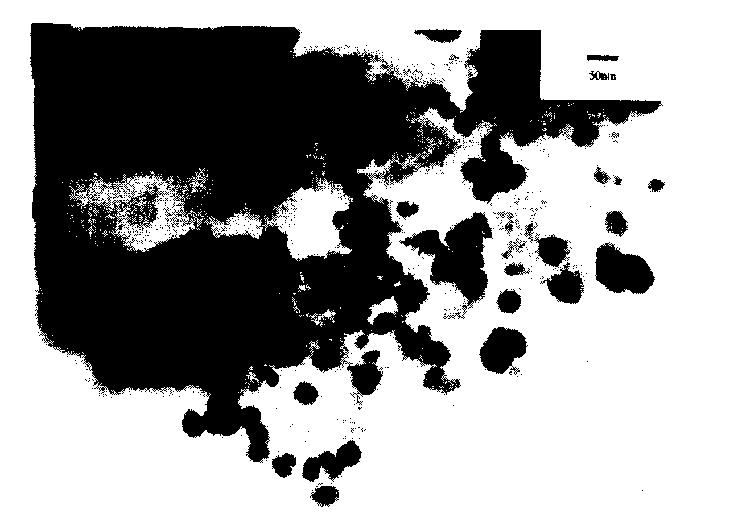

[0026] Equipped with stirrer, reflux condenser, N 2 Add 1.0g of ferrofluid, 10.0g of pyrrole, 50.0g of ethanol and 40.0g of deionized water into a 250ml four-neck bottle through the tube, stir at 300r / min, pass through N 2 . After 30 minutes, add 0.45g ammonium persulfate and react at 0°C for 10-12 hours. The obtained microspheres are magnetically separated, washed, soaked in 1M HCl to remove uncoated or incompletely coated magnetic fluid, and obtain magnetic polymer nanoparticle ball.

[0027] Add 1.5 g of dry nano-magnetic microspheres into a clean mortar, add dopant according to the required ratio, and mechanically grind at 30° C. for 8 hours. The product is dispersed in an aqueous solution to form an emulsion, magnetically separated, washed three times with methanol and ethanol, and then washed several times with water to obtain black conductive magnetic polymer nanospheres.

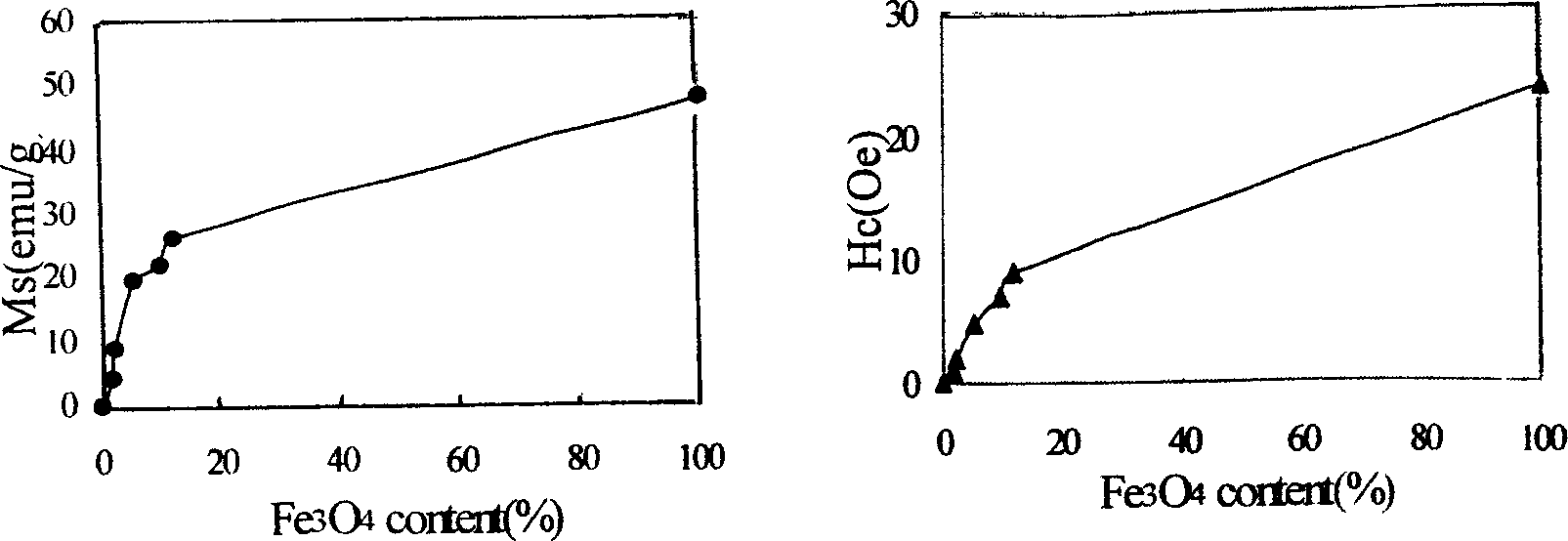

[0028] The nano-microspheres prepared by the present invention have the following characterist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com