Water polyurethane electric conduction paint containing carbon nano-tube and preparation method thereof

A water-based polyurethane and carbon nanotube technology, applied in the direction of polyurea/polyurethane coatings, conductive coatings, coatings, etc., can solve the problems of reduced conductivity and unsatisfactory shielding performance of coatings, and achieve the effect of excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

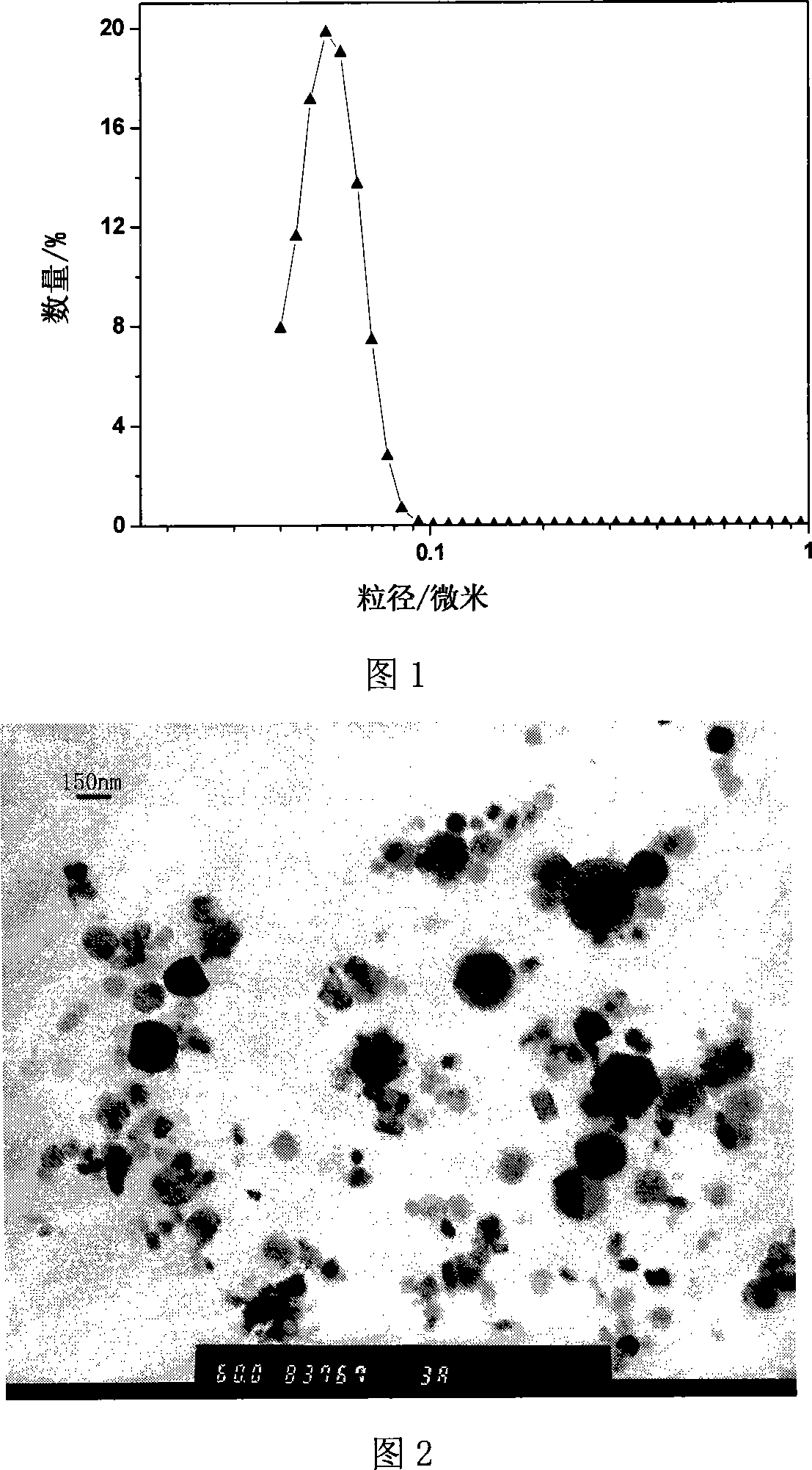

Image

Examples

Embodiment 1

[0025]Add 500 mg of multi-walled carbon nanotubes to 150 ml of a mixed strong acid solution consisting of concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:1, ultrasonically oscillate for 4 hours, pour into deionized water, and stand for more than 12 hours, filter and wash with water To neutrality, then dry to obtain chemically etched carbon nanotubes; under the protection of nitrogen, place 400 mg of the above-mentioned carbon nanotubes with carboxylic acid in excess thionyl chloride to reflux for 36 hours, after the reaction is completed, distill under reduced pressure Remove excess thionyl chloride, and vacuum-dry to obtain acid-chlorinated carbon nanotubes; then disperse 200 mg of the above-mentioned acid-chlorinated carbon nanotubes in anhydrous acetone, and add 10 ml of The acetone solution of hexamethylenediamine, the dropping time is not less than 60 minutes, continuous reaction for 12 hours, centrifugal filtration and washing to neutrality,...

Embodiment 2

[0028] Same as Example 1, but the ratio of 100:12:1:100 to 100:20:1: 100.

Embodiment 3

[0030] Same as Example 1, but the ratio of 100:12:1:100 to 100:30:1: 100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com