CNT (carbon nano tube)/macromolecule composite film and preparation method thereof

A carbon nanotube film and carbon nanotube technology, which is applied in the field of carbon nanotube/polymer composite film and its preparation, can solve the problems that composite materials cannot give full play to the electrical and mechanical properties of carbon nanotubes and poor mutual contact, and achieve The preparation method is simple and easy to operate, the thickness is controllable, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

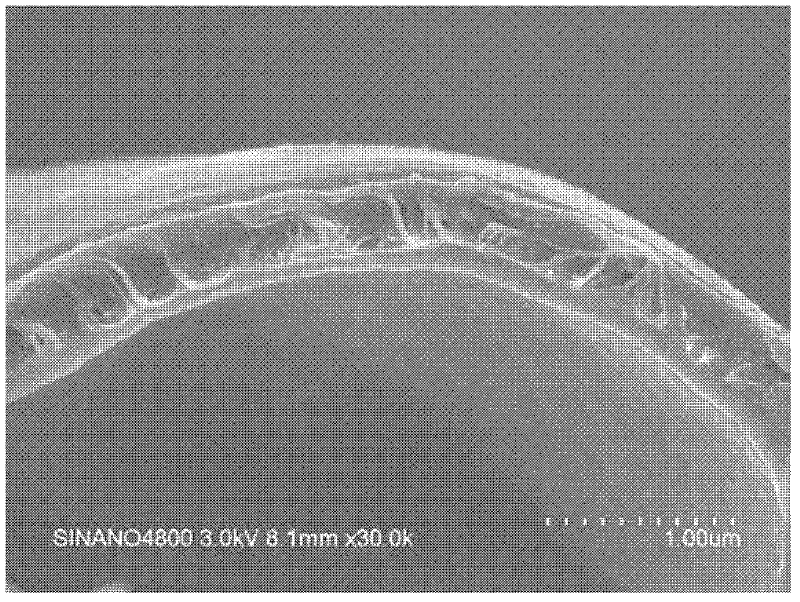

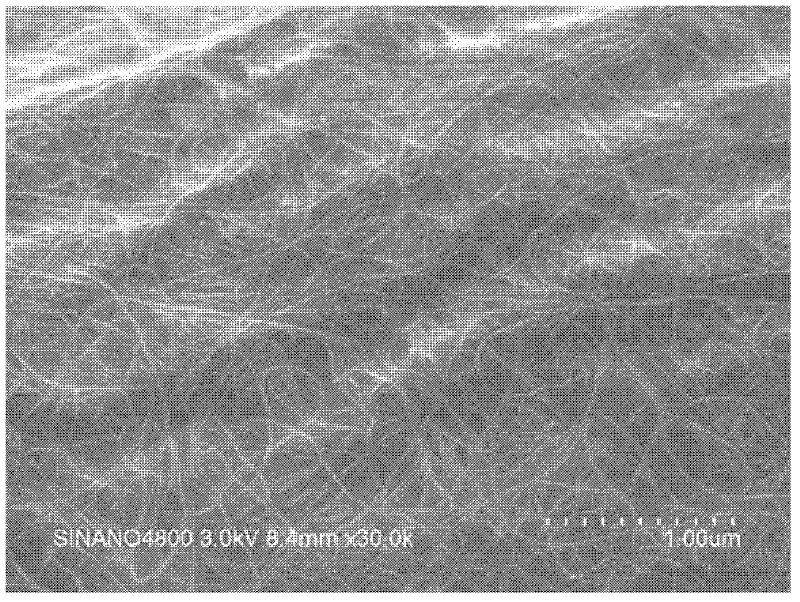

[0033] Example 1 The technical scheme of this embodiment is: weigh 3mg carbon nanotubes and 100mg sodium dodecylbenzenesulfonate, add 60ml water, ultrasonically disperse for 2-6 hours, preferably 3 hours, centrifuge, keep the supernatant; take the supernatant (that is, the carbon nanotube dispersion) is filtered through the mixed fiber porous filter membrane to form a carbon nanotube membrane, and then the porous filter membrane is dissolved to obtain a self-supporting carbon nanotube membrane, which is washed repeatedly with water to remove the surfactant.

[0034] Take epoxy resin E-44 and curing agent polyetheramine and dissolve them in acetone at a mass ratio of 5:2 to prepare a 2wt% epoxy resin pre-curing solution.

[0035] Spin-coat a layer of chitosan film on the glass sheet as a sacrificial layer, spread the aforementioned carbon nanotube film on it after drying, let it dry, and then dip the glass sheet covered with the carbon nanotube film in the above-mentioned epox...

Embodiment 2

[0037] Example 2 The technical scheme of this embodiment is: weigh 3mg carbon nanotubes, 200mg sodium dodecylsulfonate, add 30ml water, ultrasonically disperse for 5 hours, centrifuge, keep the supernatant, take the supernatant and pass it through anodized aluminum microporous filter The membrane is suction-filtered into a carbon nanotube membrane, and then the porous filter membrane is dissolved to obtain a self-supporting carbon nanotube membrane, which is washed repeatedly with water to remove the surfactant.

[0038] Take epoxy resin E-51 and trimethylhexamethylenediamine and dissolve them in ethanol at a mass ratio of 3:1 to prepare a 3wt% epoxy resin pre-curing solution.

[0039] Spin-coat a layer of cellulose acetate film on the glass sheet as a sacrificial layer, spread the carbon nanotube film on it after drying, and then immerse the glass sheet covered with the carbon nanotube film in the above epoxy resin pre-curing solution Then take it out and solidify at room t...

Embodiment 3

[0040] Example 3 The technical scheme of this embodiment is: weigh 3mg carbon nanotubes, 60mg polyoxyethylene lauryl alcohol, add 100ml water, ultrasonically disperse for 4 hours, centrifuge, keep the supernatant, take the supernatant and pump it through the polyethersulfone microporous filter membrane Filtrate into a carbon nanotube membrane, and then dissolve the porous filter membrane to obtain a self-supporting carbon nanotube membrane, which is washed repeatedly with water to remove the surfactant.

[0041]A 5wt% PVDF solution was prepared by dissolving polyvinylidene fluoride (PVDF) in N-methylpyrrolidone.

[0042] Spin-coat a layer of chitosan film on the glass sheet as a sacrificial layer, spread the carbon nanotube film on it after drying, and then immerse the glass sheet covered with the carbon nanotube film in PVDF, take it out, 60 ℃ vacuum drying. Then soak in 1wt% acetic acid aqueous solution to dissolve the chitosan sacrificial layer, and wash repeatedly with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com