Method for preparing composite material in symmetrical gradient between metallic material and ceramic material

A technology of composite materials and ceramic materials, applied in the direction of chemical instruments and methods, conductive materials, conductive materials, etc., can solve problems such as poor wettability, difficult processing of gradient materials, and large difference in sintering temperature, so as to solve the problems of difficult combination, Good electrical conductivity, realize the effect of high temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

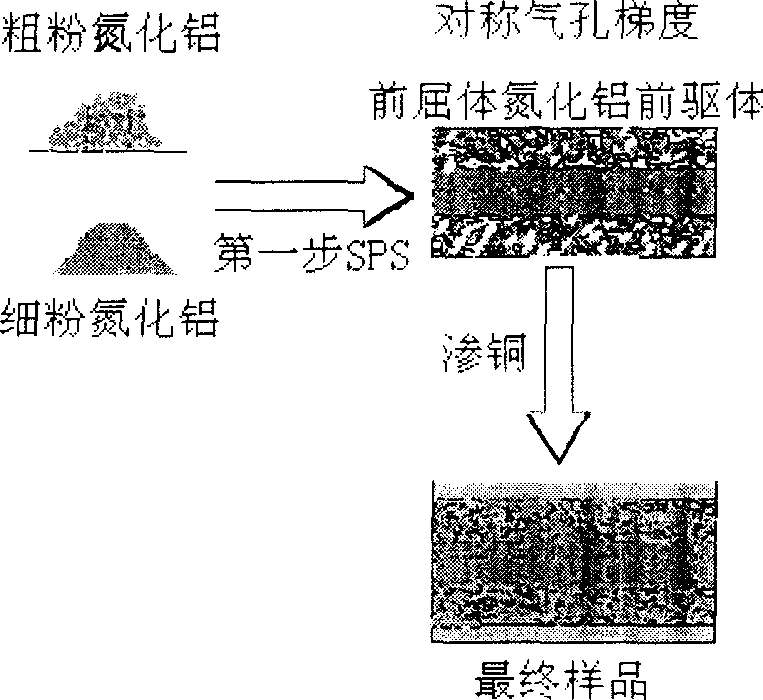

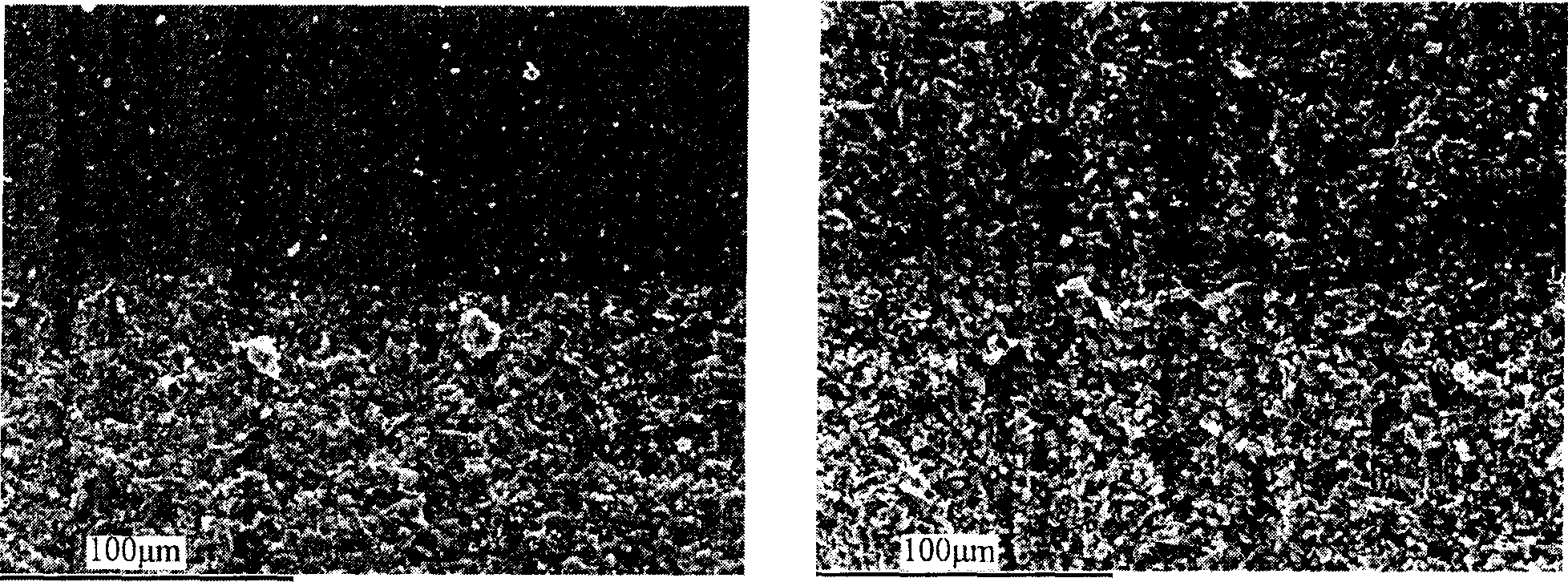

[0017] The invention provides a method for preparing a symmetrical gradient composite material of metal material and ceramic material. Take the preparation method of cermet functionally graded composite material (copper (Cu) / aluminum nitride (AlN) / copper (Cu)) as an example. The symmetric pore gradient material of multilayer aluminum nitride ceramics is prepared first, and before sintering, it is necessary to add the mass percentage of coarse powder aluminum nitride to the coarse powder aluminum nitride in the process of preparing the symmetric pore gradient material of aluminum nitride ceramics. 2-10% copper powder; then metal copper is infiltrated into the pores of the porous aluminum nitride layer on the outer layer of the symmetrical pore gradient material of aluminum nitride ceramics to achieve the purpose of layered and gradient composite. Its process (such as figure 1 shown) is:

[0018] 1) Preparation of powder raw materials: use two kinds of aluminum nitride powders...

Embodiment 1

[0025] Two kinds of aluminum nitride powders are used, the particle size is 2.20-2.45 microns, 0.97 grams of fine aluminum nitride powder with a purity of 99.9%, and 0.03 grams of calcium fluoride powder with a purity of 99.99% are mixed evenly with a grinding bowl. Then take 0.776 grams of coarse aluminum nitride powder with a particle size of 10-26 microns and a purity of more than 99%, and 0.024 grams of the same calcium fluoride, and mix them uniformly with a grinding bowl to prepare two parts in total. In addition, 2.5 grams of metal copper powder was weighed, and two parts were weighed in total.

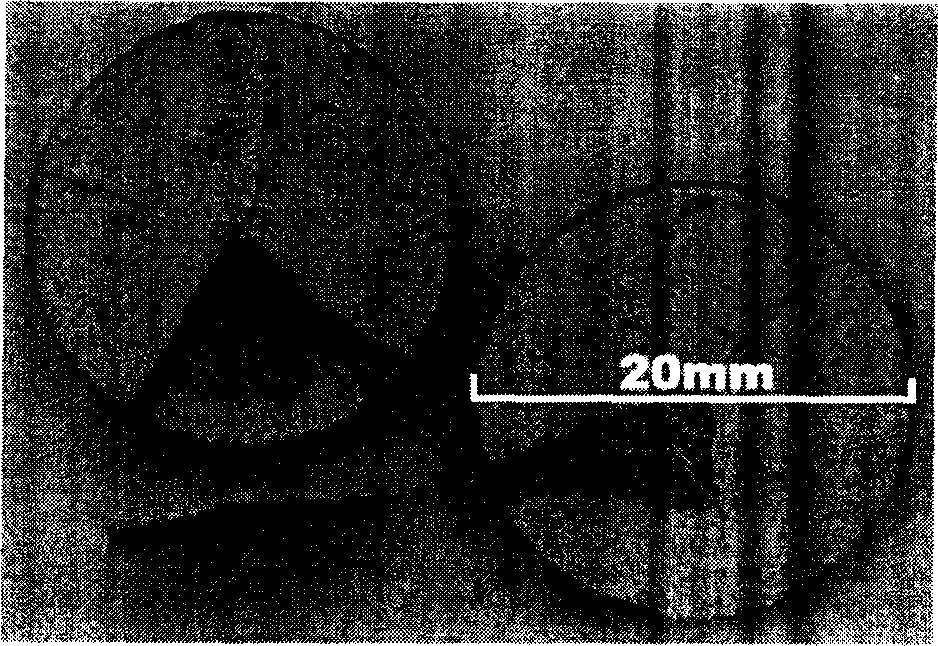

[0026] According to the order of coarse powder aluminum nitride / fine powder aluminum nitride / coarse powder aluminum nitride, press into a 20mm diameter graphite mold for spark plasma sintering, put it into a spark plasma sintering furnace after compaction, and pressurize to 40Mpa , evacuate to less than 7Pa, and measure the temperature with an infrared thermometer. The heating...

Embodiment 2

[0031] Two kinds of aluminum nitride powders are used, the average particle size is 2.35 microns, and the purity is 99.9%. Weigh 0.97 g of fine powdered aluminum nitride, and mix evenly with 0.03 g of calcium fluoride with a purity of 99.99% in a mortar. Add 8% copper powder and 3% calcium fluoride by mass percentage to 30.25 micron, 99.9% pure powdered aluminum nitride, and ball mill with a planetary mill at a speed of 200r / min for 1.5 hours. Afterwards, the ball-milled coarse aluminum nitride powder and the fine aluminum nitride powder added with calcium fluoride were mixed evenly in the ratio of 1:1 and 4:1 respectively, each weighing 0.3 g, and each proportion was divided into 2 parts. Take by weighing 2.5 grams of metal copper powder, and take two parts altogether.

[0032] According to coarse aluminum nitride / coarse aluminum nitride + 20% fine aluminum nitride / coarse aluminum nitride + 50% fine aluminum nitride / fine aluminum nitride / coarse aluminum nitride + 50% f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com