Copolymerized ester and method for making heat-shrinkable double-pipe using same

A technology of heat-shrinkable sleeve and copolyester, which is applied in the field of copolyester and the heat-shrinkable sleeve made of this copolyester, which can solve the problems of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

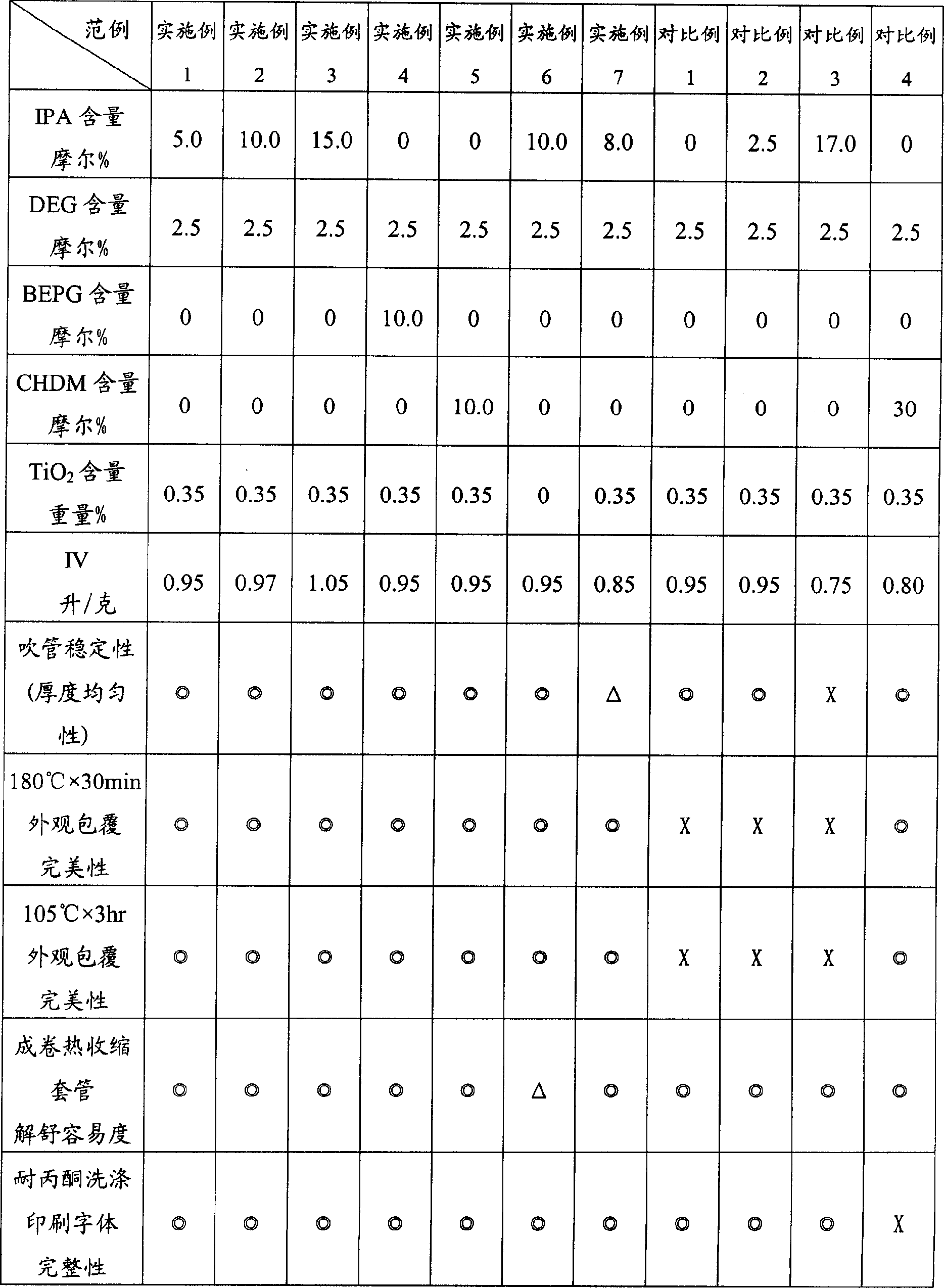

[0034] Get the diethyl terephthalate monomer (BHET) of 10.27 weight parts, and the isophthalic acid (IPA) of 0.432 weight parts and 3.243 weight parts ethylene glycol (EG) are put into reaction tank, when material temperature reaches 190 Above ℃, the esterification reaction starts, and the reaction pressure is 1.0-1.5Kg / cm 2 , react for 180 minutes to make the esterification rate reach more than 95%, add 0.035 parts by weight of titanium dioxide, stabilizer phosphoric acid, and catalyst antimony acetate, and then start vacuuming, so that the temperature of the material is 250 ~ 280 ° C and the reaction is under a vacuum environment of 1 torr When the viscosity is above 0.60 liters / g, it is unloaded and cooled to form cylindrical amorphous raw particles; then the prepared raw particles are put into the solid-state polymerization reaction device, so that the temperature of the ester particles is 190~ At 220°C, increase the viscosity of the ester pellets to 0.95 liters / gram under...

Embodiment 2

[0038] As in Example 1, but the diethyl terephthalate monomer (BHET) of 9.73 parts by weight and the isophthalic acid (IPA) of 0.864 parts by weight are put into a reactor for reaction, after completing the melt polymerization, Carry out solid-state polymerization to increase the viscosity to 0.97 liters / gram; then, carry out various tests on the heat-shrinkable sleeve made, and the results are shown in Table 1 in detail.

Embodiment 3

[0040] As in Example 1, but the diethyl terephthalate monomer (BHET) of 9.186 parts by weight and the isophthalic acid (IPA) of 1.296 parts by weight are put into a reactor for reaction, and then carry out after completing the melt polymerization The solid-state polymerization increases the viscosity to 1.05 liters / gram. When the polyester of this embodiment is carrying out solid-state polymerization, it needs a gentler heating and heating condition than that of Example 1, otherwise agglomeration will occur; The casing sleeve was tested for various tests, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com