Inorganic flake water-based epoxy resin coating

A technology of water-based epoxy resin and flakes, applied in the field of coatings, can solve the problems of not having moisture-proof effect, not achieving moisture-proof effect, affecting service life, etc., to solve the defects of moisture-proof, low shrinkage rate and high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the present embodiment, the water-based epoxy resin coating comprises the first component and the second component, wherein:

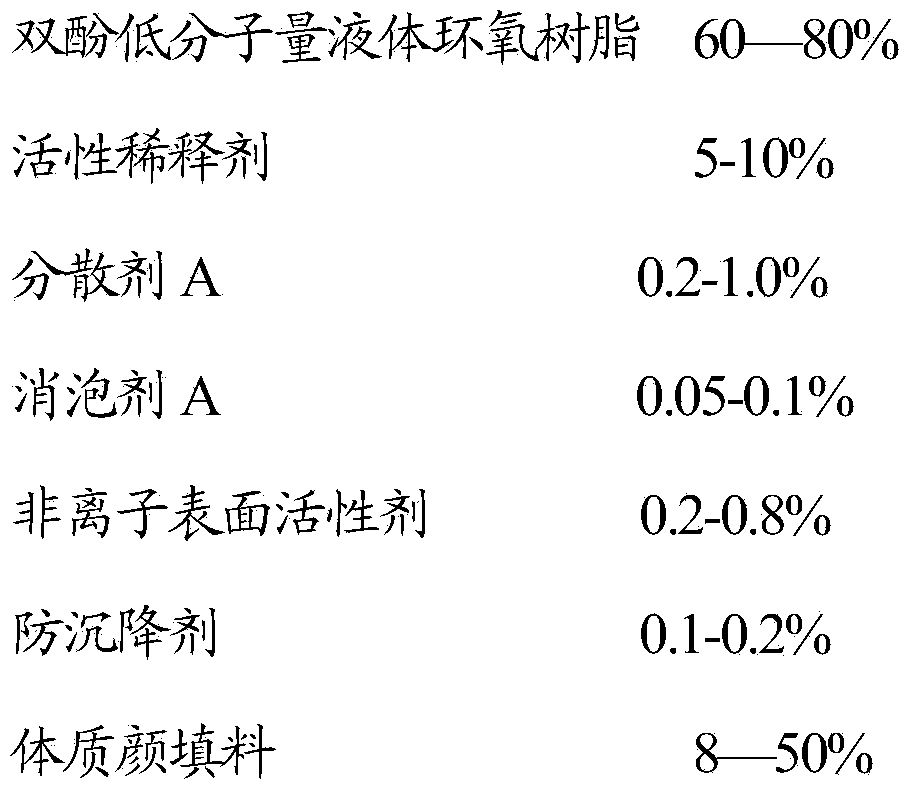

[0044] Component A comprises the following raw materials in percentage by weight:

[0045]

[0046] Component B includes raw materials in the following weight percentages:

[0047]

[0048] Wherein, the bisphenol low molecular weight liquid epoxy resin in the first component is E51 epoxy resin;

[0049] The reactive diluent in component A is propylene oxide butyl ether 660 type.

[0050] Dispersant A in component A is a modified polyacrylate wetting and dispersing agent, preferably Efconer EFKA4560.

[0051] The defoamer A in component A is a general-purpose strong defoamer, preferably MONENG-2477 or EFKA-2722.

[0052] The nonionic surfactant in Part A is alkylphenol polyoxyethylene ether (APEO).

[0053] The inorganic flaky filler in component A is sericite.

[0054] What is the ratio of talcum powder and precipitated barium sulf...

Embodiment 2

[0060] The water-based epoxy resin coating in the present embodiment comprises A component and B component, wherein:

[0061] Component A comprises the following raw materials in percentage by weight:

[0062]

[0063] Component B includes raw materials in the following weight percentages:

[0064]

[0065] Among them, the bisphenol low molecular weight liquid epoxy resin in component A is E51 / 128 type epoxy resin;

[0066] The reactive diluent in component A is propylene oxide butyl ether 660 type.

[0067] Dispersant A in component A is a modified polyacrylate wetting and dispersing agent, preferably Efconer EFKA4560.

[0068] The defoamer A in component A is a general-purpose strong defoamer, preferably MONENG-2477 or EFKA-2722.

[0069] The nonionic surfactant in component A is high-carbon fatty alcohol polyoxyethylene ether (AEO).

[0070] The inorganic flake filler in component A is glass flake.

[0071] Preferably, the anti-settling agent in component A is me...

Embodiment 3

[0077] The water-based epoxy resin coating in the present embodiment comprises A component and B component, wherein:

[0078] Component A comprises the following raw materials in percentage by weight:

[0079]

[0080] Component B includes raw materials in the following weight percentages:

[0081]

[0082]

[0083] Among them, the bisphenol low molecular weight liquid epoxy resin in component A is E51 / 128 type epoxy resin;

[0084] The reactive diluent in component A is propylene oxide butyl ether 660 type.

[0085] Dispersant A in component A is a modified polyacrylate wetting and dispersing agent, preferably Efconer EFKA4560.

[0086] The defoamer A in component A is a general-purpose strong defoamer, preferably MONENG-2477 or EFKA-2722.

[0087] The nonionic surfactant in component A is high-carbon fatty alcohol polyoxyethylene ether (AEO).

[0088] The inorganic flake filler in component A is glass flake.

[0089] Preferably, the anti-settling agent in compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com