Spooling transport vehicle and automatic spindle conveying system and method

A winding and trolley technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., to achieve the effect of reducing management costs, reducing labor intensity, and reducing the chance of pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

[0062] The automatic spindle conveying system of the present invention is a fully automatic automatic system that completely replaces manual work, and aims to realize the automatic conveying of spindles in the chemical fiber industry from the forming area to the quality inspection area, while greatly reducing the manpower demand and labor intensity of workers , to reduce the chance of the spindle being polluted and damaged.

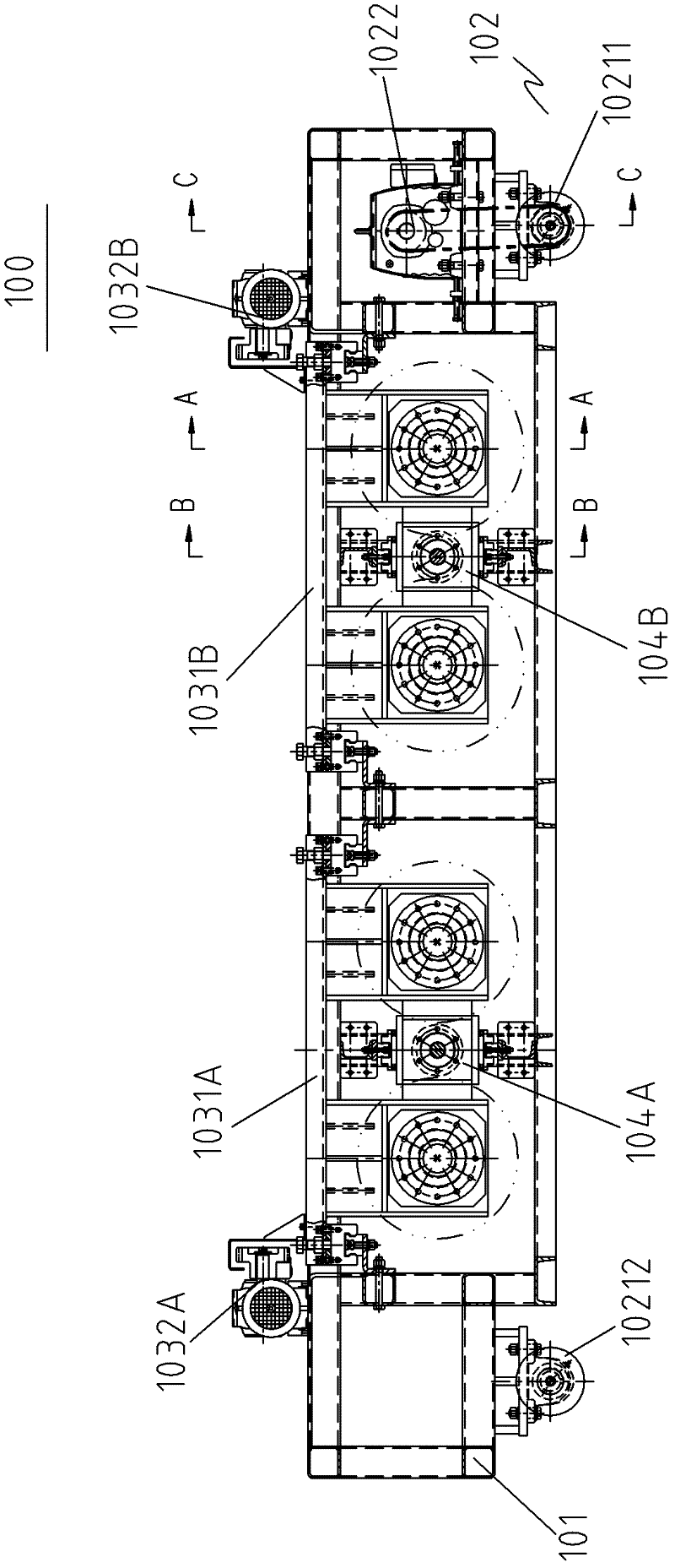

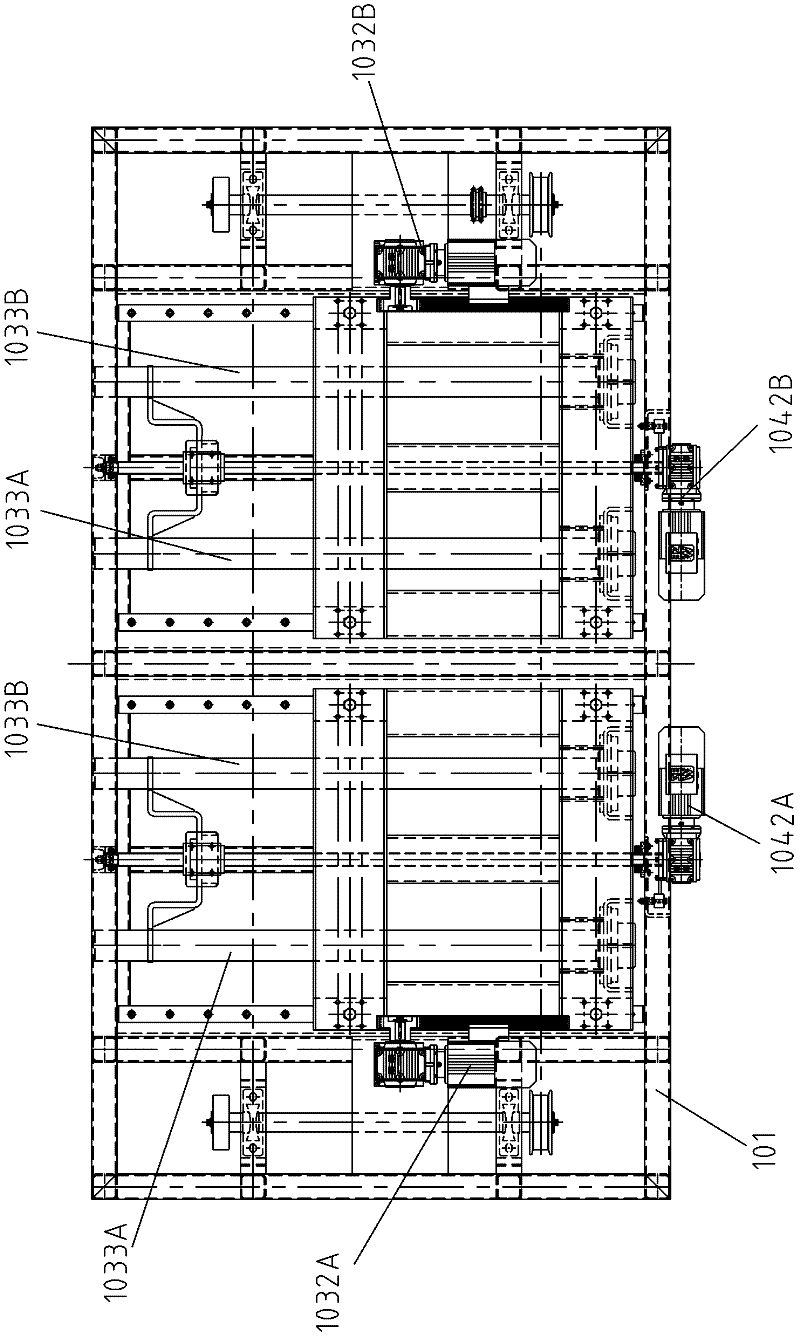

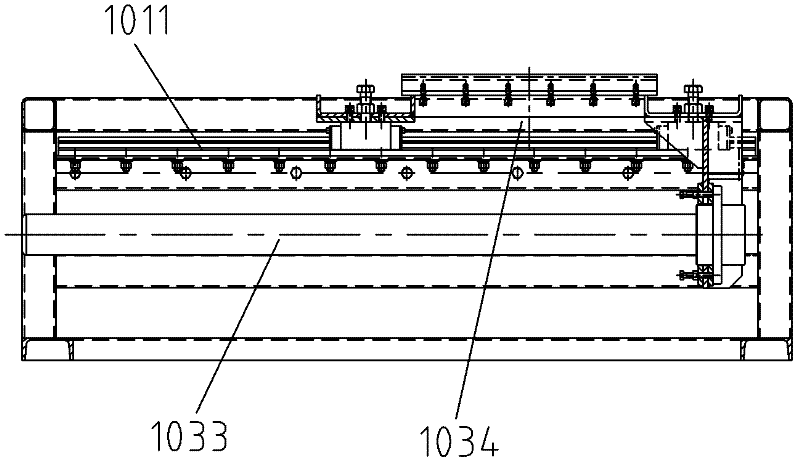

[0063] refer to Figure 6 and Figure 7, as shown in the figure, the automatic spindle conveying system of the present invention is set between the winding machine 500 and the special yarn car 600, and is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com