Equipment used for visual positioning and angle detection of solar cells before series welding

A technology of solar cells and visual positioning, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as workpiece damage, low accuracy, and workpiece crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: A device for visual positioning and angle detection before stringing of solar cells.

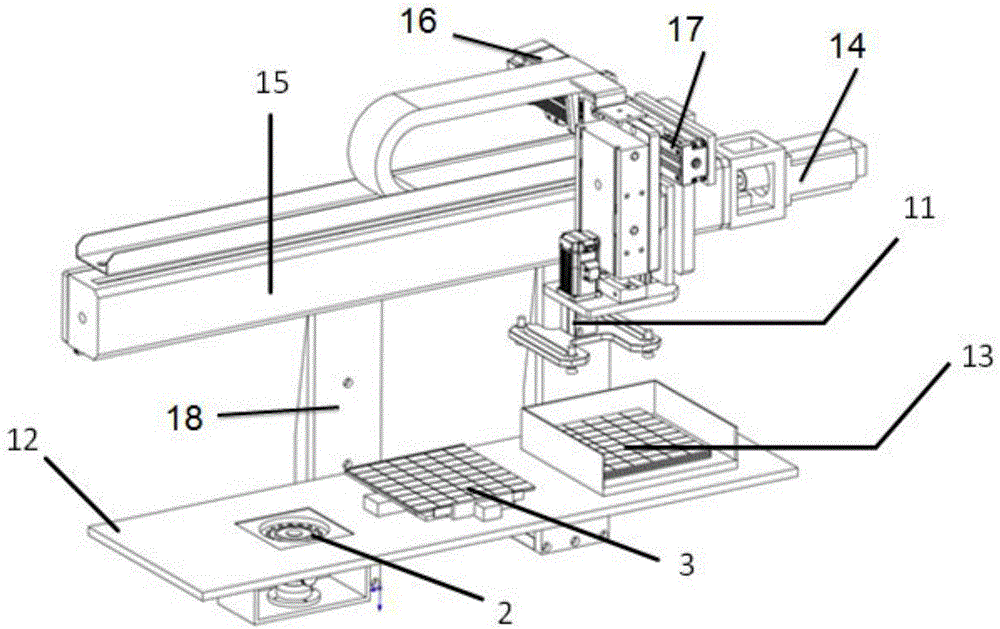

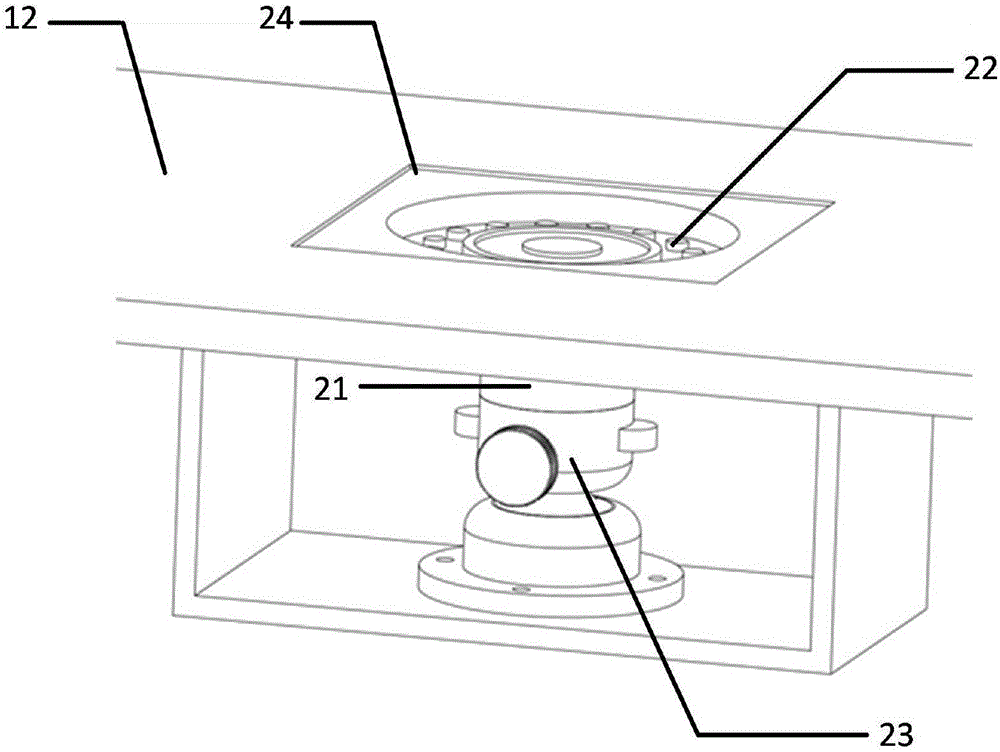

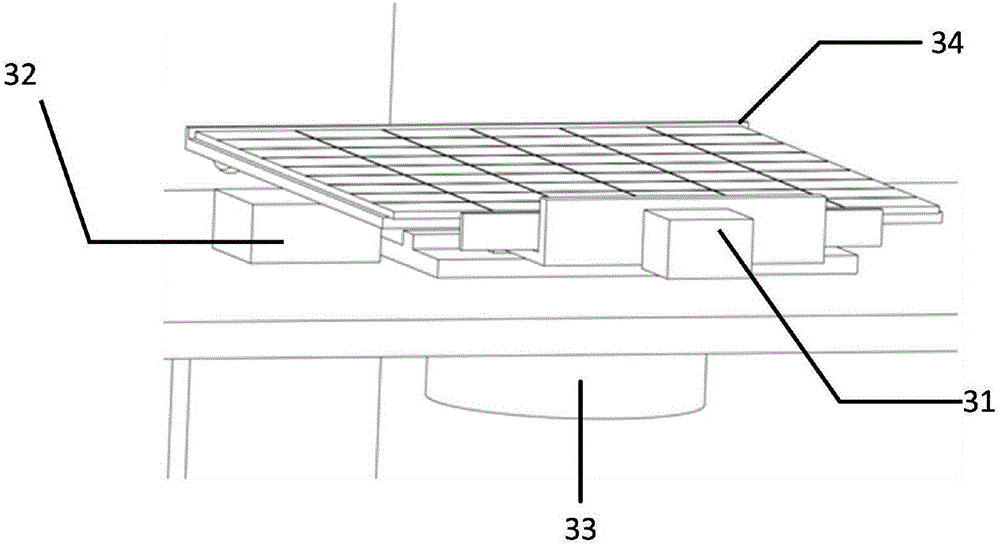

[0082] refer to Figure 1 to Figure 3 As shown, a kind of visual positioning and angle detection equipment before stringing solar cells, including: support frame 18; Y-axis slide rail 15 fixed on the top of support frame 18; The X-axis slide rail 17 that is installed on the Y-axis slide rail 15 and can move along the direction of the Y-axis slide rail 15; the X-axis drive motor 16 that is installed at the end of the X-axis slide rail 17; is installed on the X-axis slide rail 17 and can The manipulator 11 that moves along the direction of the X-axis slide rail 17; the support platen 12 installed on the front side of the support frame 18 and below the Y-axis slide rail 15, the surface of the support platen 12 is provided with through holes; The imaging mechanism 2 in the through hole of the plate 12, the imaging mechanism 2 includes a camera 21, a light source 22 and a hori...

Embodiment 2

[0088] Embodiment 2: A method for visual positioning and angle detection before stringing of solar cells.

[0089] refer to Figure 4 As shown, a detection method based on the visual positioning and angle detection equipment before the solar cell string welding provided by the present invention specifically includes two parts: equipment initialization and continuous operation of the equipment. The equipment initialization specifically includes the following steps:

[0090] S11, camera 21 mechanical position calibration: manually adjust the leveling bracket 23, and observe the bubbles on the leveling bracket 23

[0091] position, when the bubble is in the middle position, turn the set screw to lock the horizontal alignment bracket 23 so that the camera 21 shoots vertically upwards

[0092] Adjust the focal length of the lens so that the workpiece can be clearly imaged within a certain depth range;

[0093] S12. Calibrate camera parameters: set (x, y) as the two-dimensional co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com