Grasping force active compliance control method of apple picking robot tail end actuator

A technology for end effectors and picking robots, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., and can solve problems such as inability to achieve compliant grasping control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

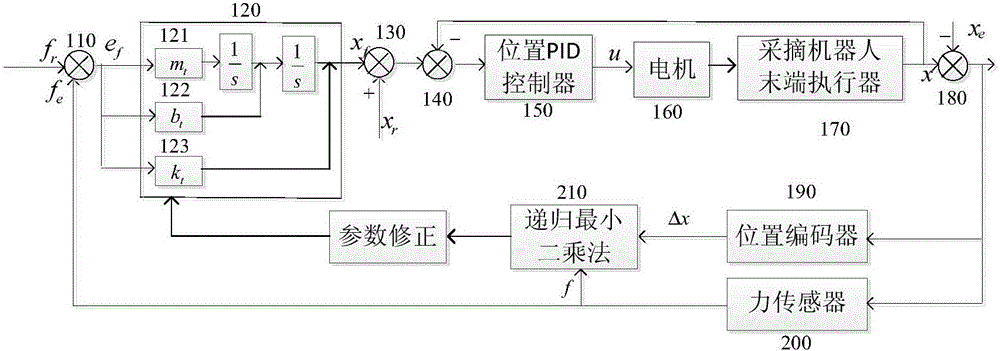

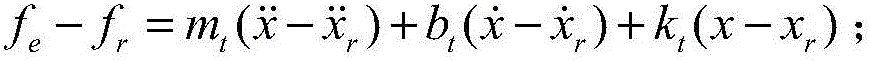

[0034] An active compliance control method for the gripping force of an apple picking robot based on impedance control, comprising the following steps:

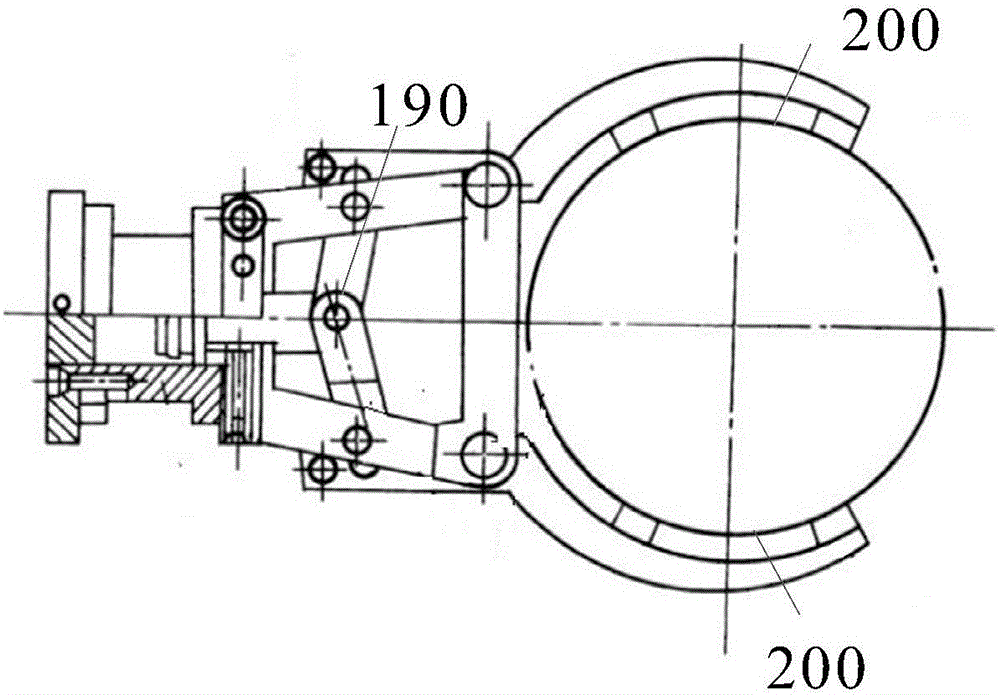

[0035] 1) Use the FSR 402 force-sensitive resistive force sensor 200 to measure the grasping force f of the end effector, and use the information of the TRD-NA1024NW position encoder 190 to obtain the displacement transformation amount Δx of the end effector, and then obtain the grasping force and displacement The signal is input to the online identifier to identify the environment and the equivalent stiffness coefficient k of the controller eq , and through the established second-order impedance and first-order admittance model y=k eq ·△x, find out the stiffness coefficient in the impedance controller.

[0036] 2) Using the force sensor 200 and the position encoder 210 to grasp the force f of the end effector r and the displacement variable △x, within a sampling period, N times of sampling are carried out, and N>3, the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com