Device for preparing carbon film on inner wall of quartz ampoule used for monocrystal growth

A technology of quartz ampoule and preparation device, applied in the field of materials, can solve the problem of uneven carbon film and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention. For the sake of clarity and simplicity, detailed descriptions of known functions and constructions in the devices described herein will be omitted when it may obscure the subject matter of the present invention.

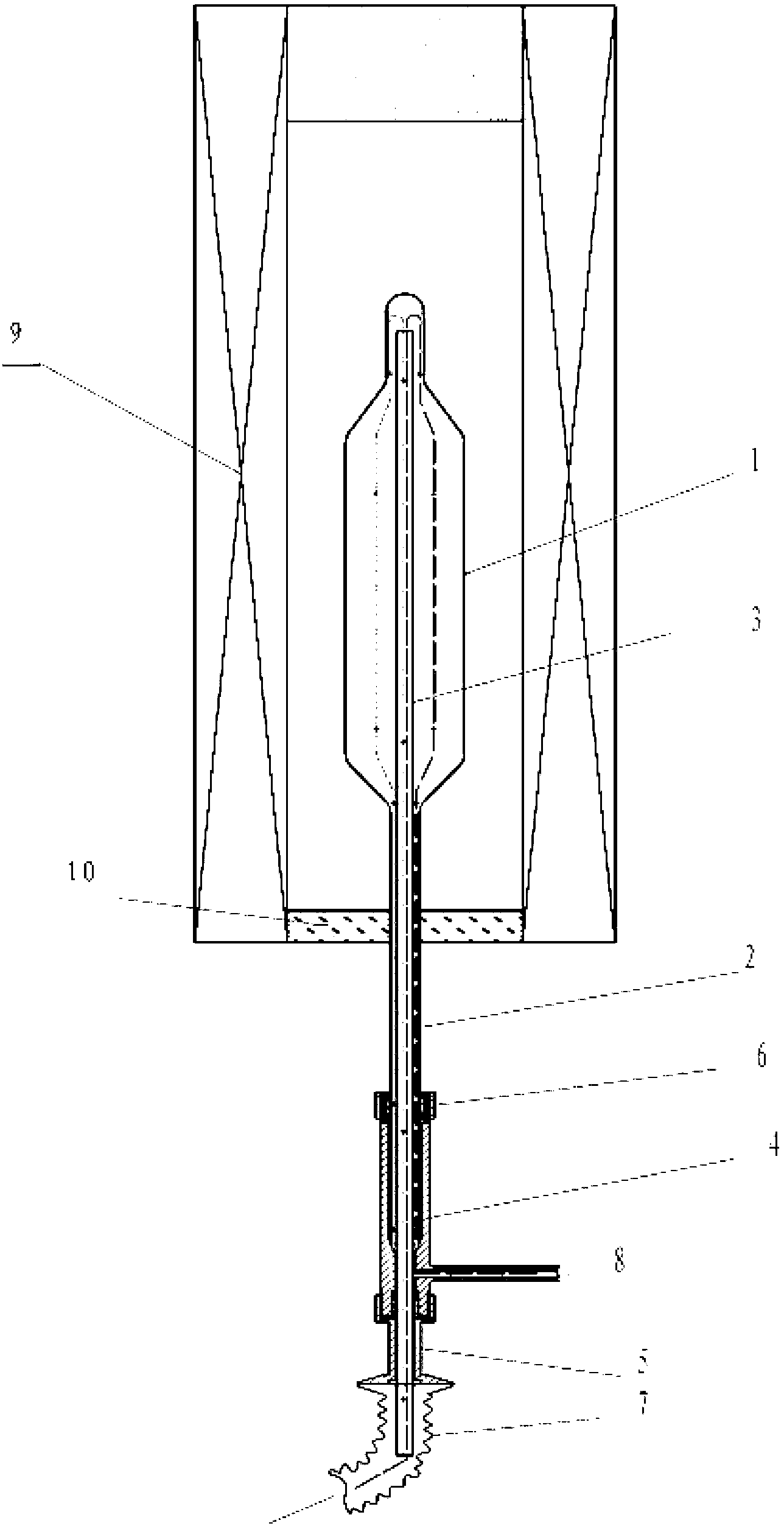

[0021] The embodiment of the present invention provides a device for preparing a carbon film on the inner wall of a quartz ampoule for single crystal growth, see figure 1 The unit includes:

[0022] The quartz ampoule 1 is vertically arranged in the heating furnace 9, and the furnace mouth of the heating furnace 9 is provided with a plug 10 for sealing the heating furnace 9;

[0023] An ampoule support is arranged on the neck 2 of the quartz am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com