Method for extracting coal bed gas in stable mining region by ground well drilling

It is a technology of mining stable area and ground drilling, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc. It can solve the problems of large amount of buried pipe engineering, drilling accidents, poor economy, etc., and achieve the goal of drilling structure and The construction technology is reasonable, the possibility of damage is reduced, and the effect of improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

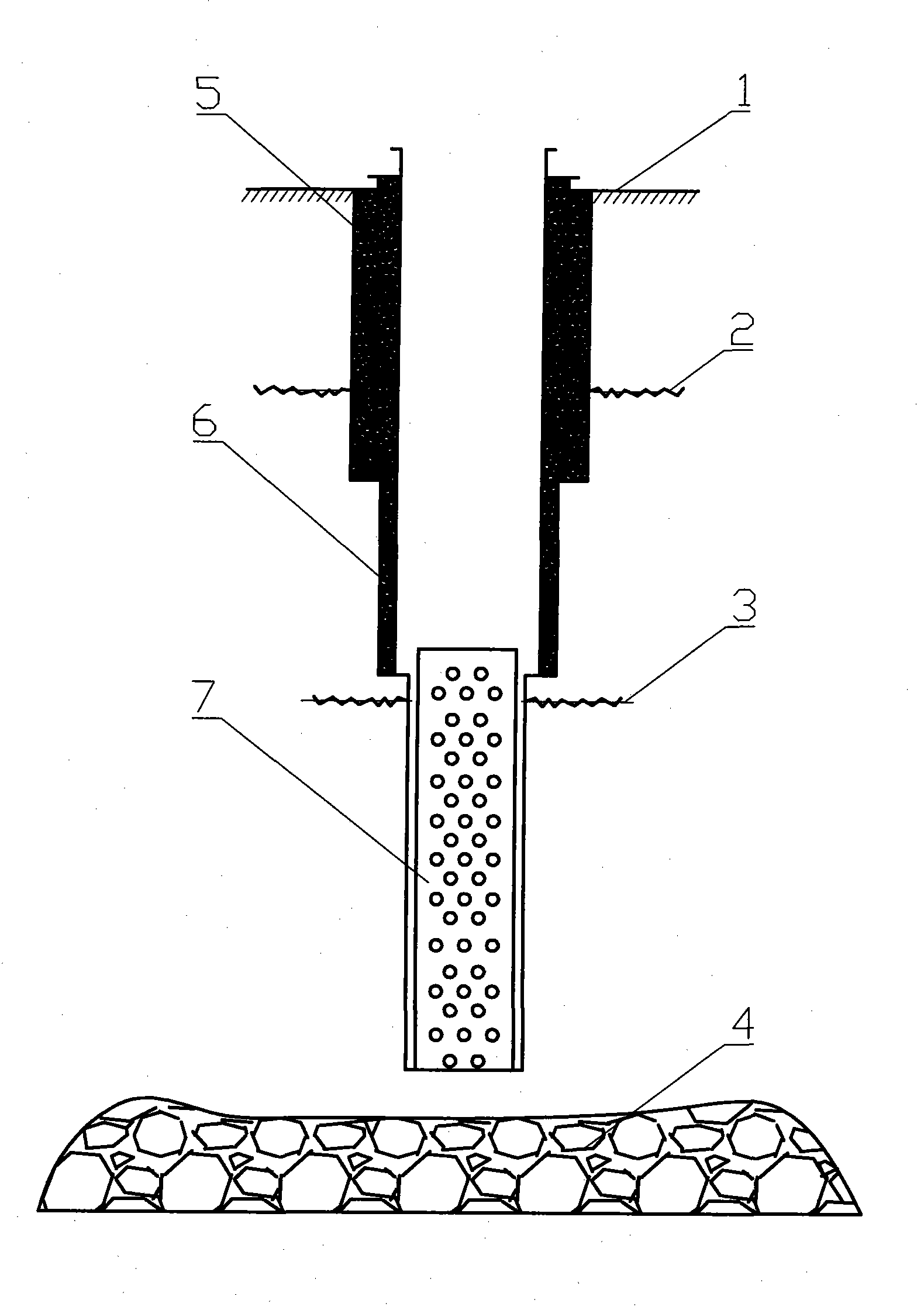

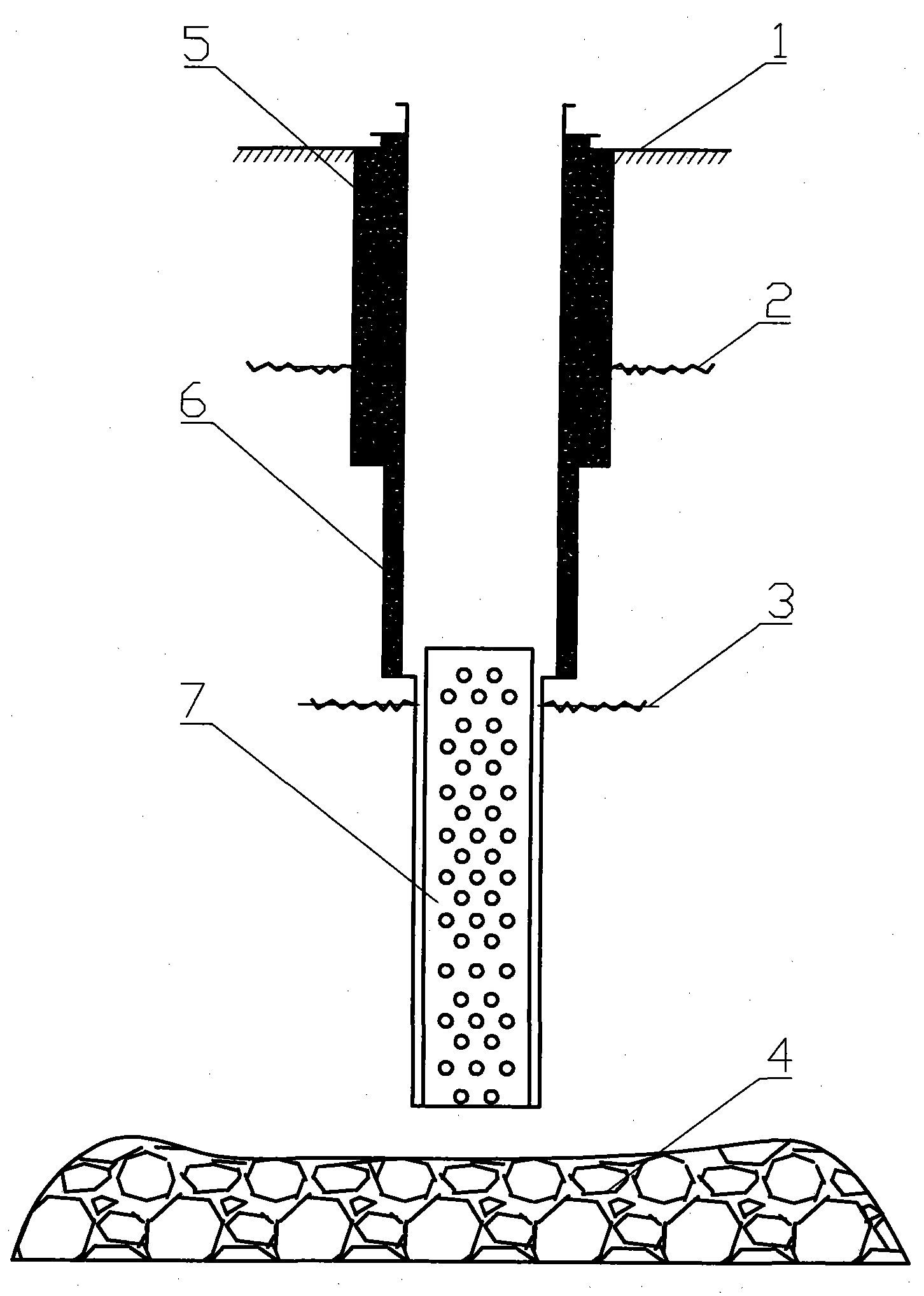

[0021] Accompanying drawing is a schematic diagram of the drilling structure of the present invention, as shown in the figure: the method for extracting coalbed methane in a stable area by ground drilling in this embodiment comprises the following steps:

[0022] 1) Hole layout: According to the existing mining drawings and parameters of the coal seam and overlying strata in the mining stable area, select the hole layout points for ground drilling in the mining stable area. Compared with the overlying rock in the middle of the mining stable area, the overlying strata on both sides of the stable area are less likely to collapse, and have higher stability. Choosing this place as the hole layout point can improve the drilling construction process on the one hand. On the other hand, it can effectively reduce the probability of drilling being damaged. The spacing of the holes along the strike is 200-300m. The holes are arranged according to the drainage radius of the drilling, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com