Automatic production line of total heat exchange core, and cutting and conveying structure thereof

A technology of automatic production line and full heat exchange core, applied in metal processing and other directions, can solve the problem of troublesome film suction process, and achieve the effect of high degree of automation, high blanking efficiency and good blanking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

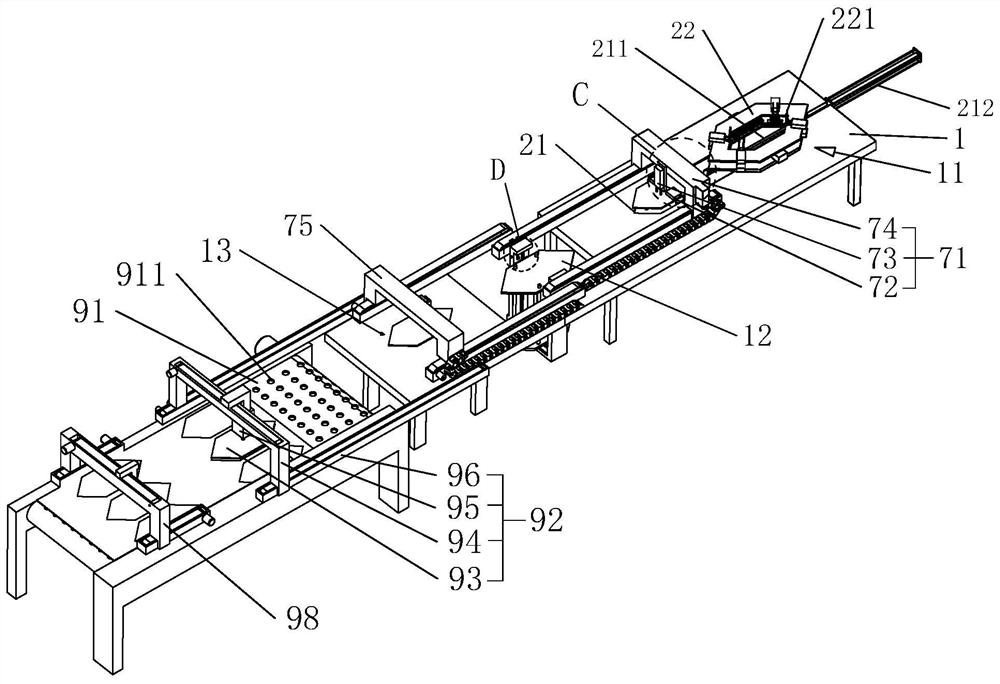

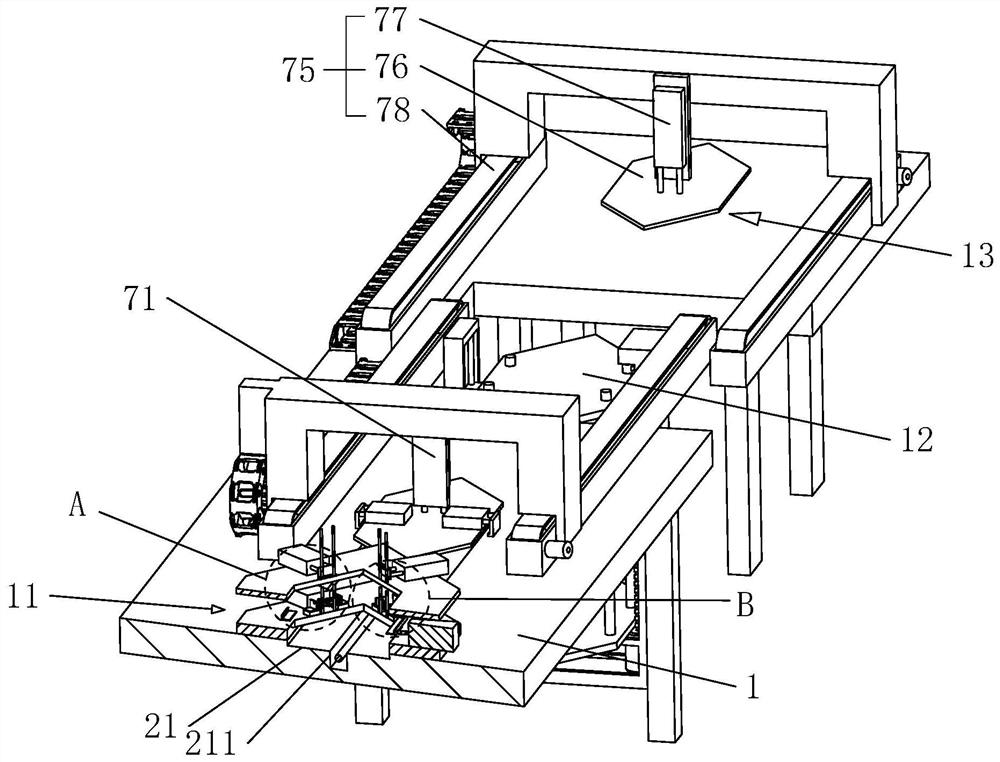

[0047] The following is attached Figure 1-12 The application is described in further detail.

[0048] The embodiment of the present application discloses an automatic production line of a total heat exchange core and its cutting and conveying structure. refer to figure 1 , including a frame 1, the frame 1 is provided with a blanking station 11, a stacking platform 12, a film placement station, a conveyor belt 91, a conveying mechanism 92, an auxiliary lifting mechanism and a cutting mechanism 98.

[0049] The blanking station 11 is provided with a blanking mechanism and a first conveying mechanism 71, the stacking platform 12 is arranged between the blanking station 11 and the diaphragm placement station, and a The second delivery mechanism 75.

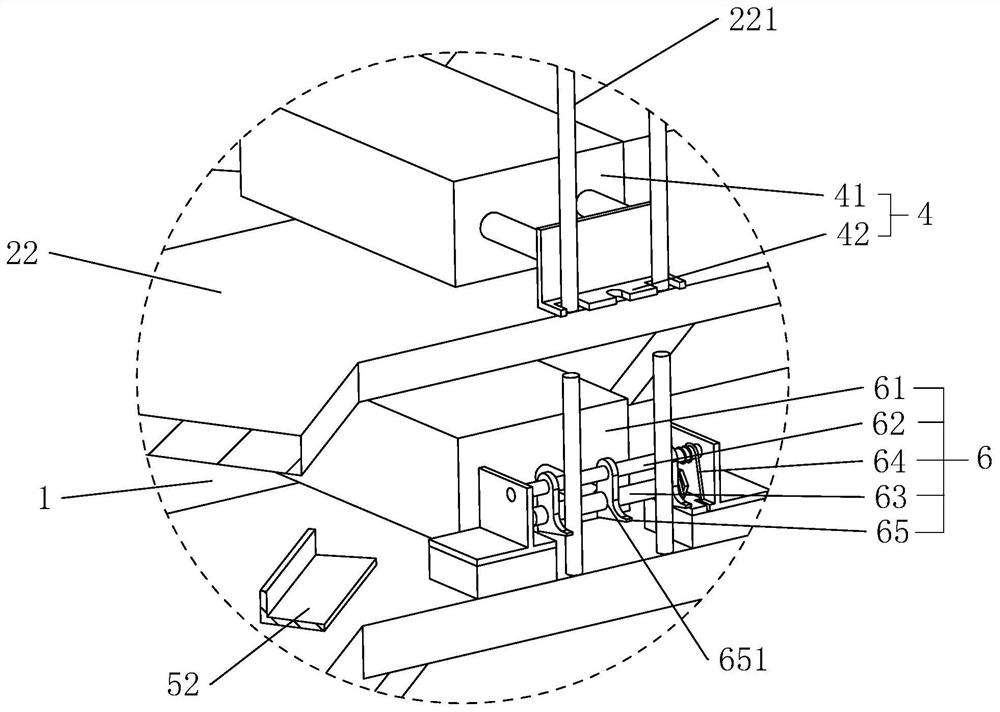

[0050] like figure 2 , image 3 as well as Figure 4 As shown, the blanking mechanism includes a blanking trough 21 , a positioning frame 22 , a first supporting mechanism 3 , a second supporting mechanism 4 , a third supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com