Backlight module, manufacturing method thereof and display device

A technology of backlight module and manufacturing method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as uneven light mixing of backlight modules, pulling of light-emitting chips, etc., and achieve the effect of reducing leakage and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

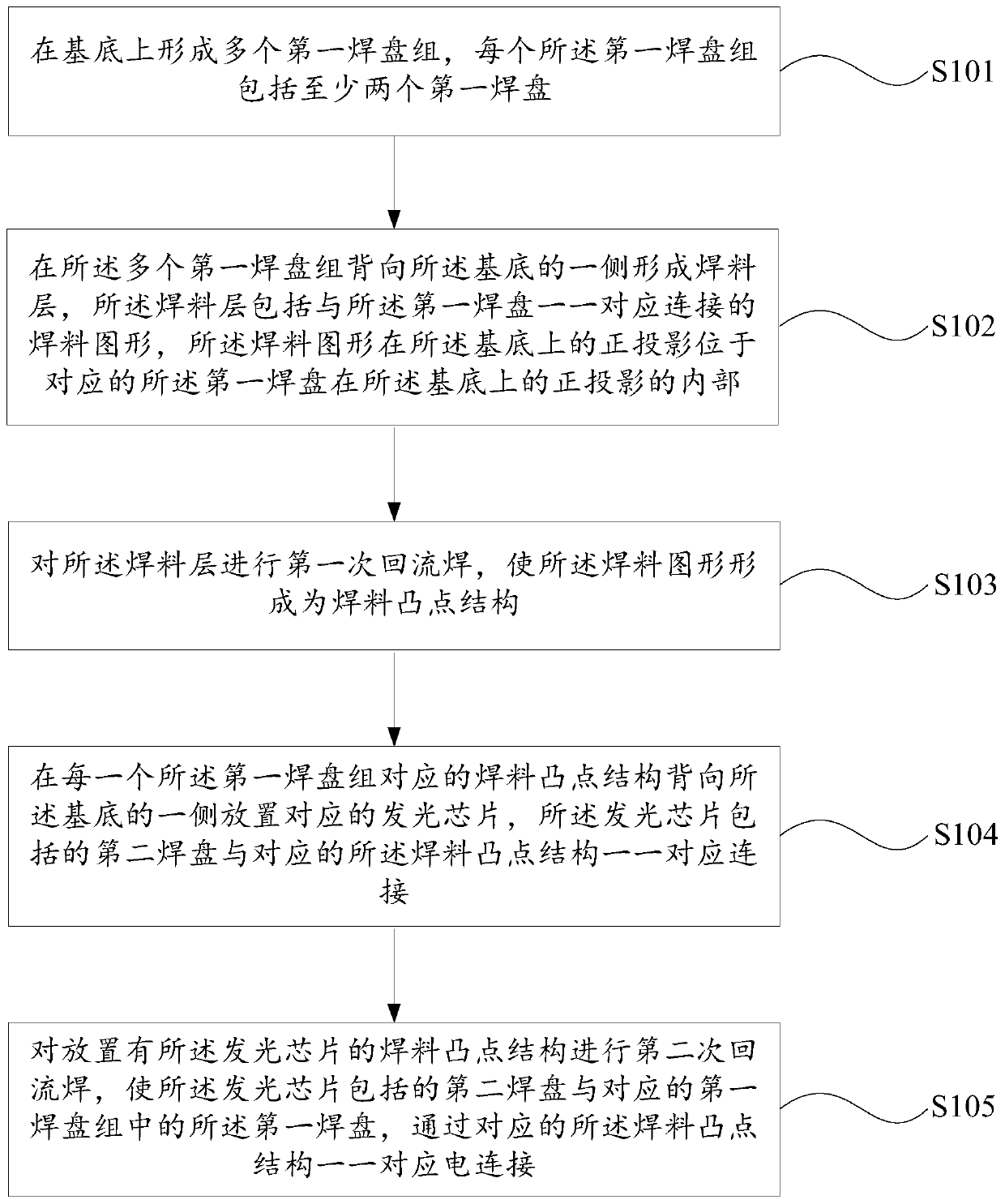

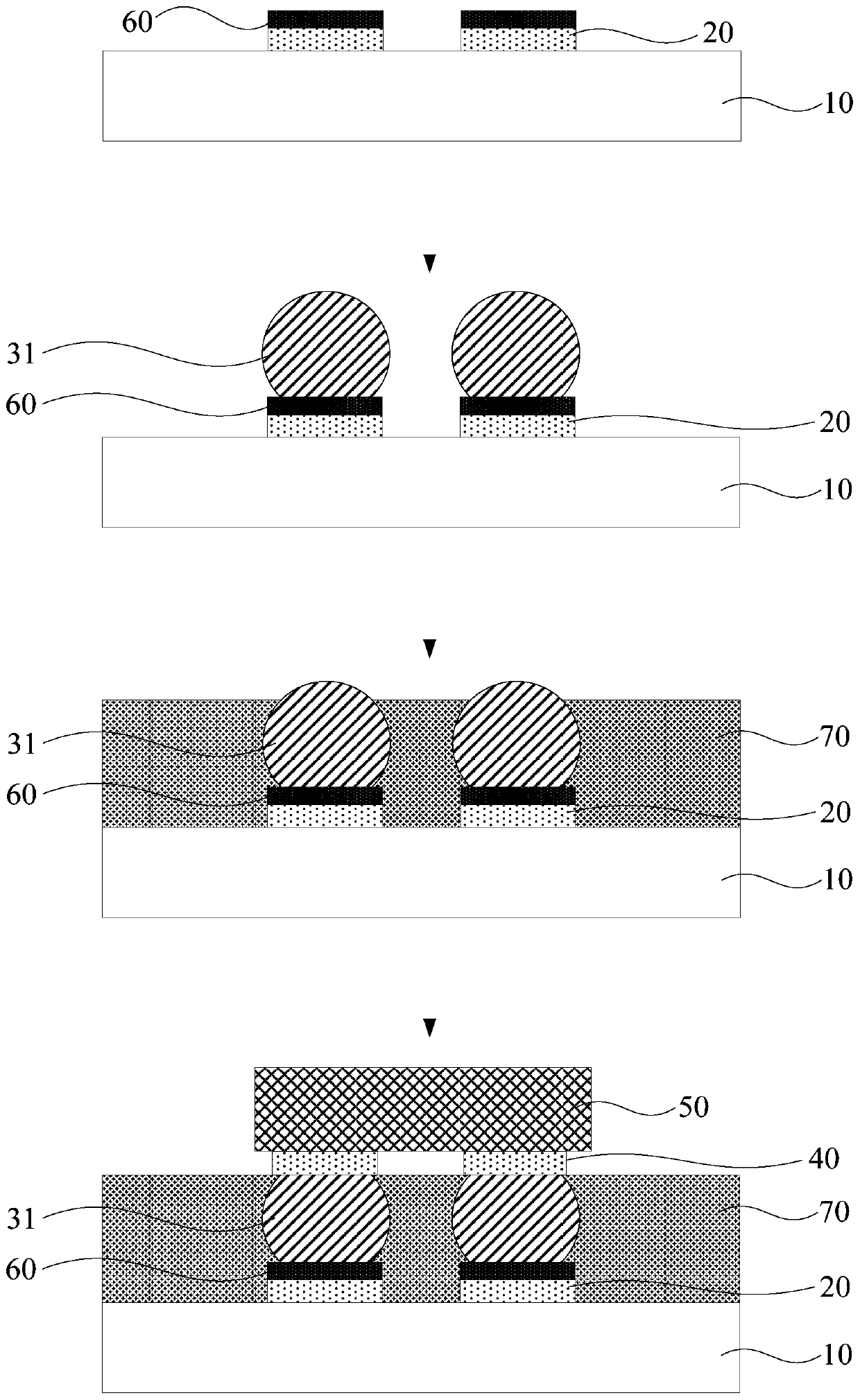

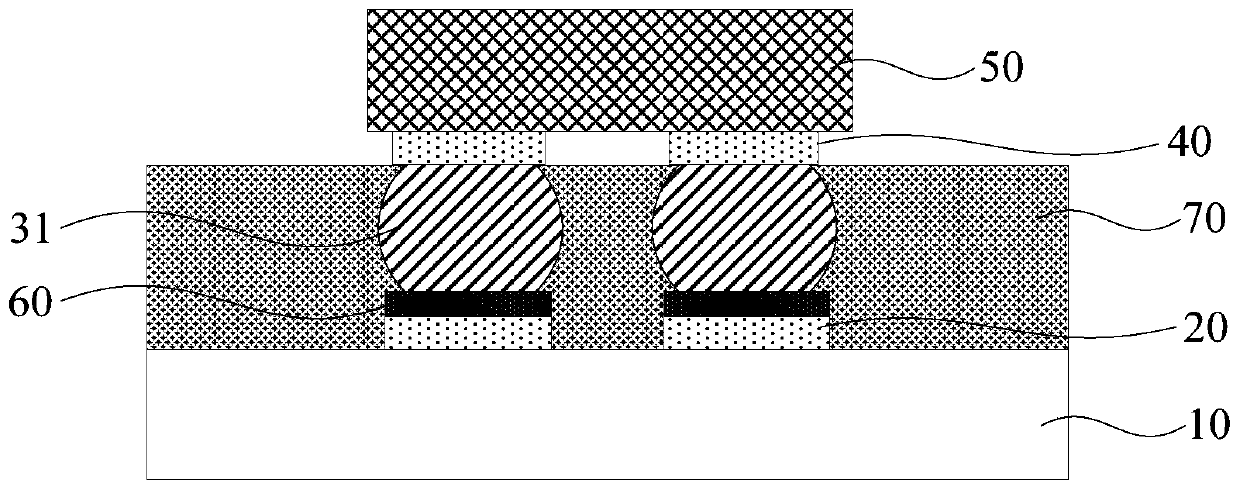

[0043] In order to further illustrate the backlight module, its manufacturing method, and display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

[0044] In the related art, when Mini LED is used as the light source structure in the backlight module, the number of Mini LED used in the backlight module is increasing, and as the size of the Mini LED chip is continuously reduced, it is difficult to make the backlight module. The difficulty of the process puts forward higher requirements.

[0045] When making traditional miniature light-emitting diode (Mini LED) backlight modules, first print solder paste on the substrate, then place the Mini LED chip on the printed solder paste, and then fix the Mini LED chip on the substrate through a reflow process. However, this production method currently has the following problems:

[0046] (1) In the traditional solder paste printing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com