Layer-dismantling and stacking system and layer-dismantling and stacking method

A palletizing system and control system technology, which is applied in the field of intelligent cargo stacking to achieve the effect of facilitating subsequent sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

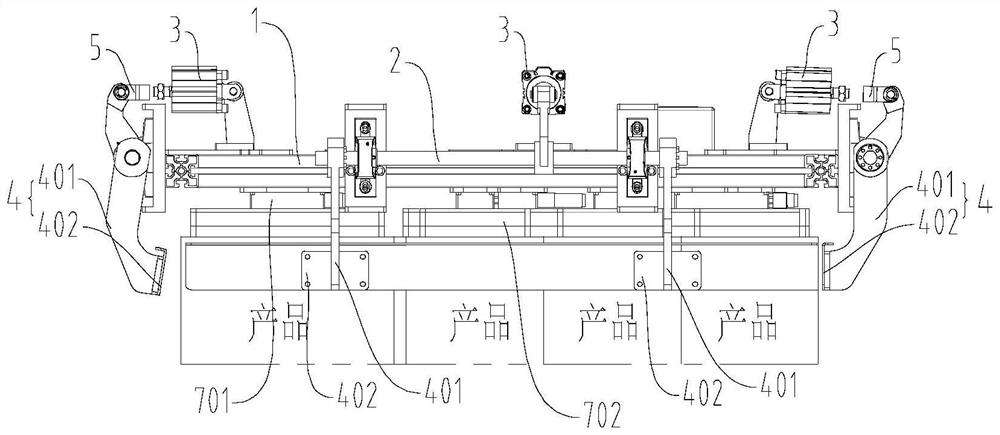

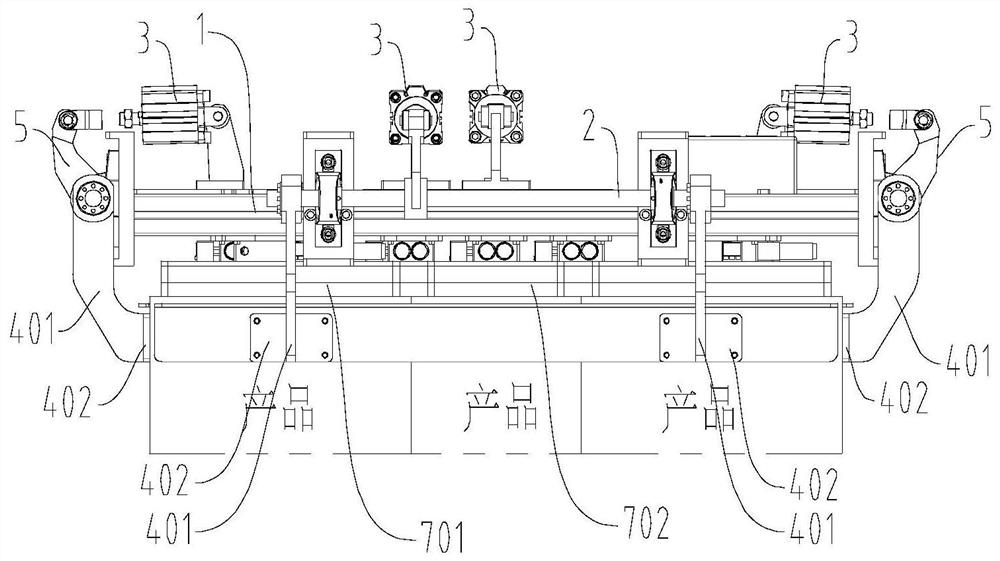

[0112] refer to Figure 7 to Figure 8 , the stack type detection mechanism is used to detect the arrangement form of the single-layer goods on the conveying line, that is, the form of the horizontal and vertical arrangement of the cargo boxes 12 in the goods on the top floor, including:

[0113] frame 10;

[0114] Bracket: installed on the frame 10, located above the conveying line, including bracket one 11011 and bracket two 11012 arranged at intervals;

[0115] Strut: including the first 11021 and the second 11022.

[0116] Bracket one 11011 is installed on the frame 10, the first end of pole one 11021 passes through bracket one 11011, and the second end is restricted on bracket one 11011; the detection switch one 11031 is arranged on the side of the second end of pole one 11021 , can be triggered when the support pole 11021 moves relative to the frame 10;

[0117] The first end of the second pole 11022 passes through the second pole 11012, and the second end is restricted ...

Embodiment 2

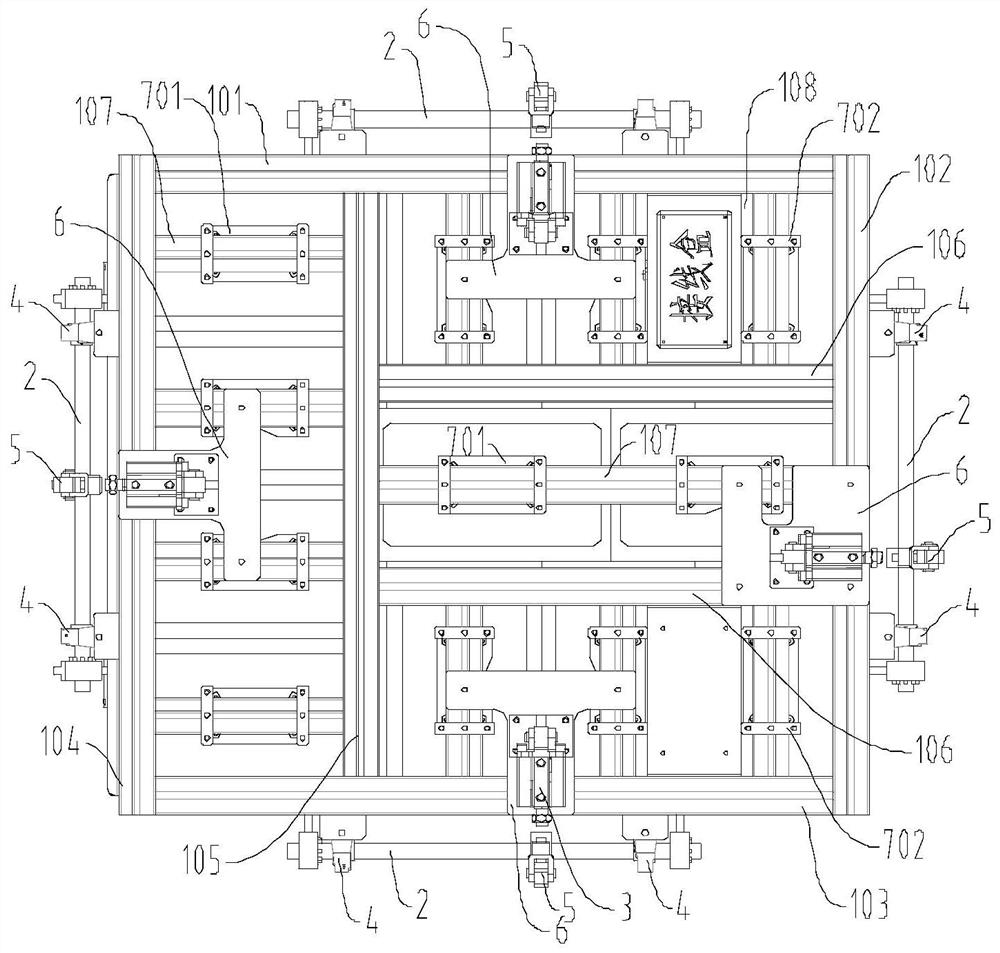

[0128] structure reference Figure 12 with Figure 13 . The stack type detection mechanism is used to detect the arrangement form of the single-layer goods on the conveying line, that is, the form of the horizontal and vertical arrangement of the cargo boxes 12 in the goods on the top floor, including:

[0129] The first detection assembly includes a first pivot lever 1301 pivotally mounted on the frame, a first detection switch 1302 is arranged in the rotation direction of the first pivot lever 1301, and can be rotated when the first pivot lever 1301 rotates relative to the frame 10 is triggered;

[0130] The second detection assembly includes a second pivot lever 1401 that can be pivotally mounted on the frame, and a second detection switch 1402 is arranged in the rotation direction of the second pivot lever 1401, and can be rotated when the second pivot lever 1401 rotates relative to the frame 10 is triggered.

[0131] Specifically, the detection switch is set in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com