Automatic boxing system adopting robot

A technology of automatic boxing and robotics, applied in the fields of automatic packaging control, packaging, packaging food, etc., can solve the problems of low automatic boxing efficiency and affecting production efficiency, and achieve reasonable allocation of calculation and communication processes, improve efficiency, and stabilize the system sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

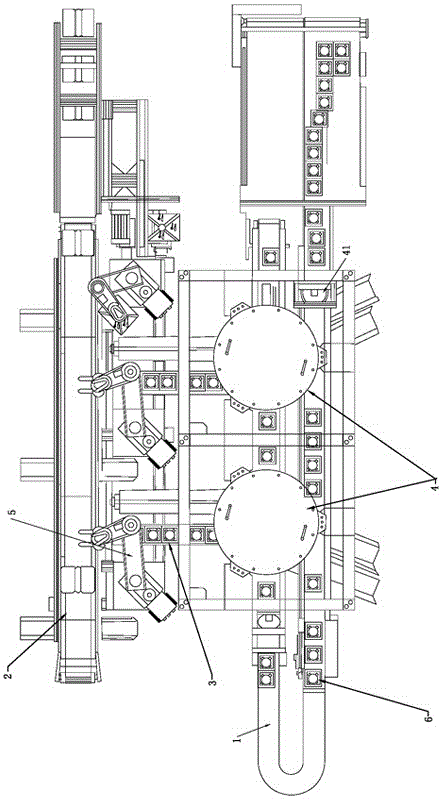

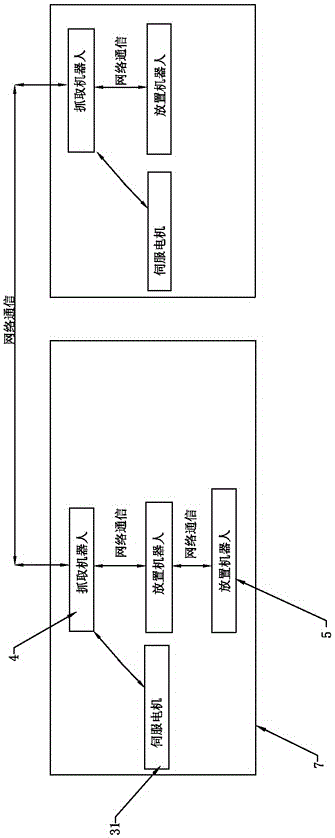

[0021] The present invention creates a specific embodiment of an automatic boxing system using a robot, such as figure 1 As shown, it includes: a first conveyor belt 1, a second conveyor belt 2 and two working groups 7. Each working group 7 includes a cache device 3 and a grasping robot 4 as the main robot. The grasping robot 4 grabs the product 6 to be loaded from the first conveyor belt and places it in the buffer device 3. The grasping robot 4 includes The grasping host and the visual device 41, the visual device 41 is arranged on the first conveyor belt, and the grasping host is a grasping host integrated with drive and control (delta robot). The visual device 41 takes image information of the products 6 on the first conveyor belt 1 and transmits the image information to the grasping host. The buffer device 3 includes a conveying belt and a servo motor 31 for driving the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com