Quantitative racking machine of biscuit

A quantitative filling machine and biscuit technology, which is applied in the direction of packaging biscuits, packaging, packaging food, etc., can solve the problems of low work efficiency, high biscuit production cost, inconsistent biscuit quantity, etc., achieve a high degree of mechanization and automation, and reduce labor consumption , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

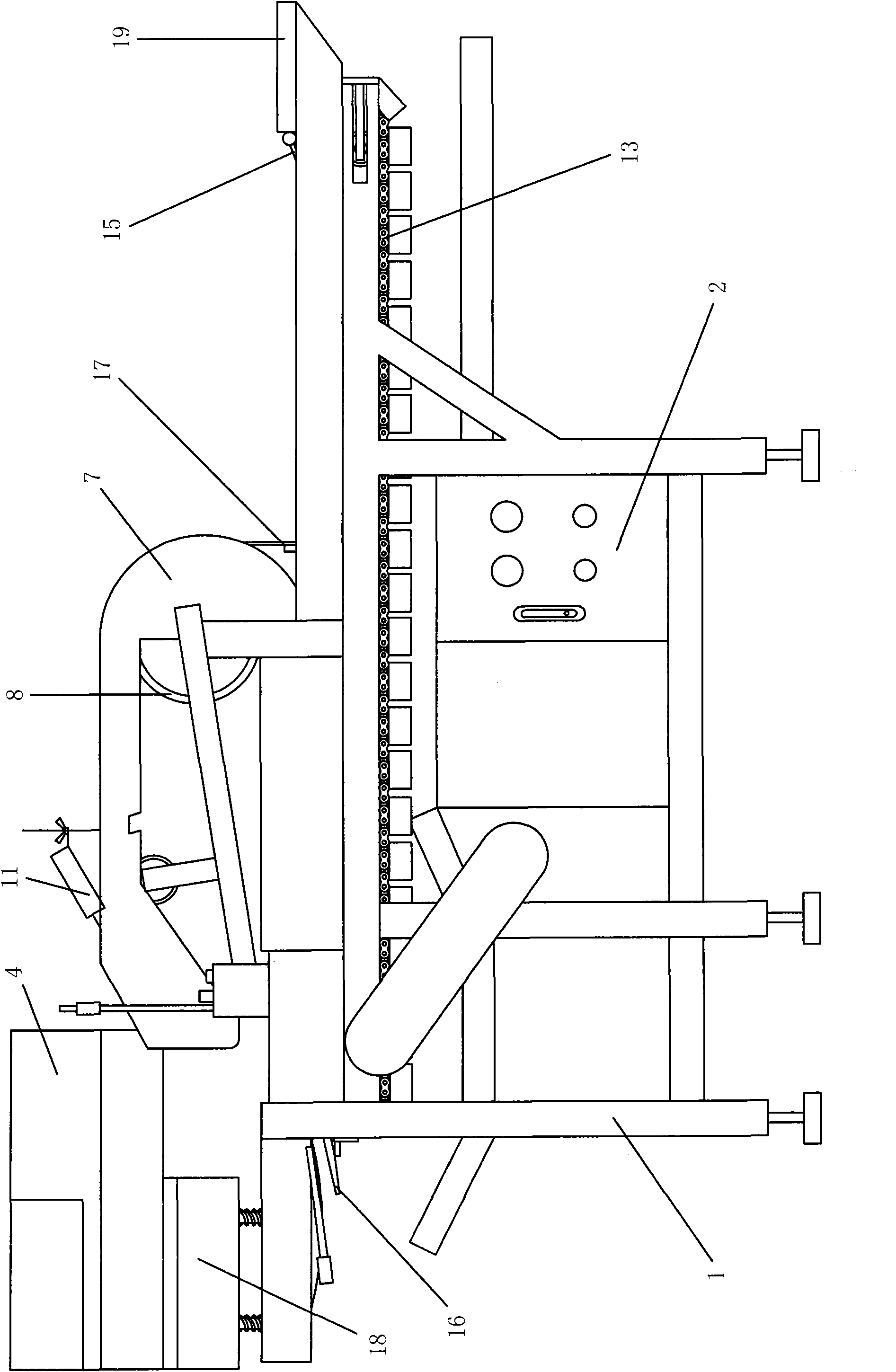

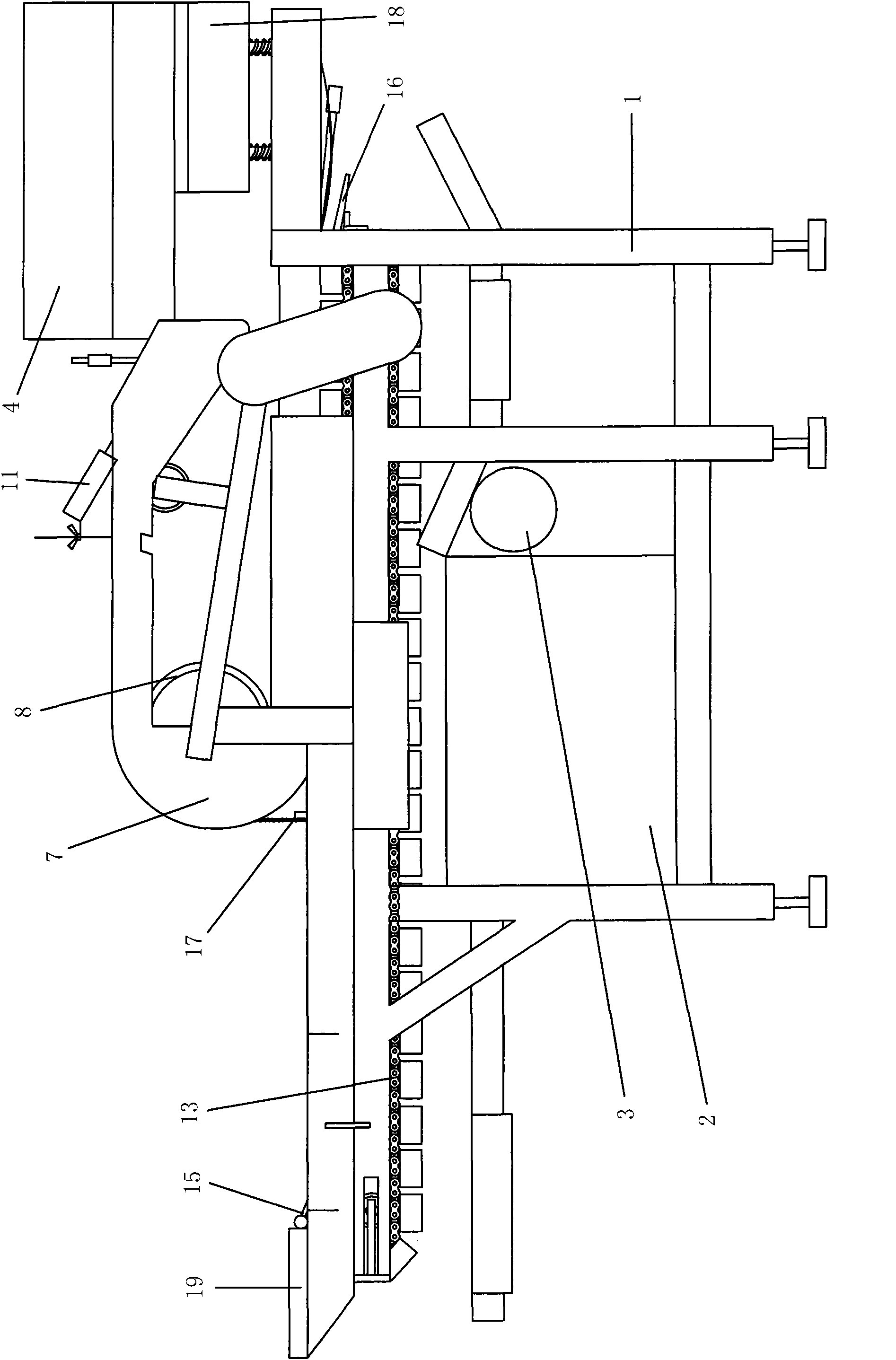

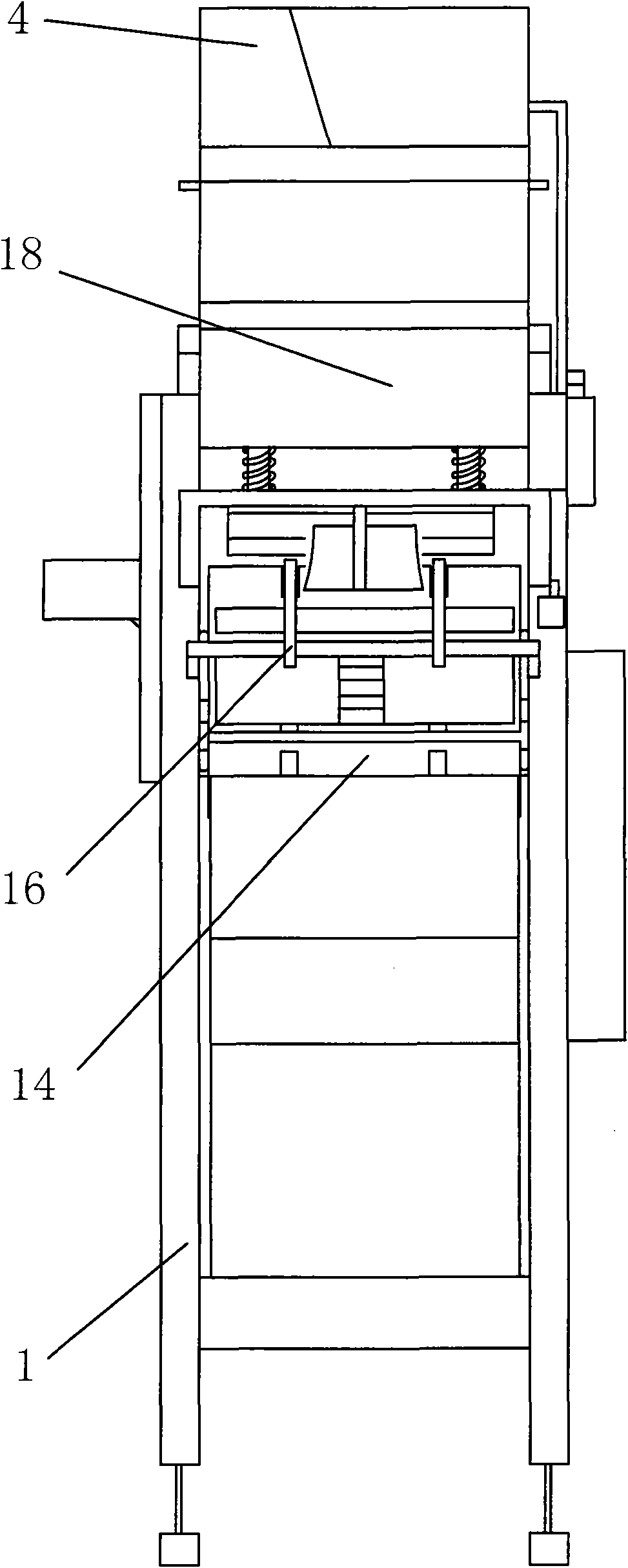

[0020] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a kind of biscuit quantitative dispensing machine described in the present embodiment, comprises frame 1, electric control box 2, motor 3, power transmission mechanism, feeding mechanism, dispensing mechanism, packing mechanism and safety insurance device 17, electrical control Box 2, motor 3, power transmission mechanism, and packaging mechanism are respectively installed on the frame 1, and the packaging mechanism installed on the frame 1 is located on the upper part of the packaging mechanism, and the packaging mechanism is matched with the packaging mechanism. The feeding mechanism on the frame 1 is located at one end of the sub-packaging mechanism, and the feeding mechanism is matched with the sub-packaging mechanism. The safety device 17 at one end is installed on the frame 1 , and the motor 3 and the safety device 17 are electrically connected to the electrical control box 2 respectively.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com