Primary packaging device for lunar surface sampling

A packaging device, primary technology, applied in the direction of sampling device, etc., to achieve the effect of convenient sample transfer and reliable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

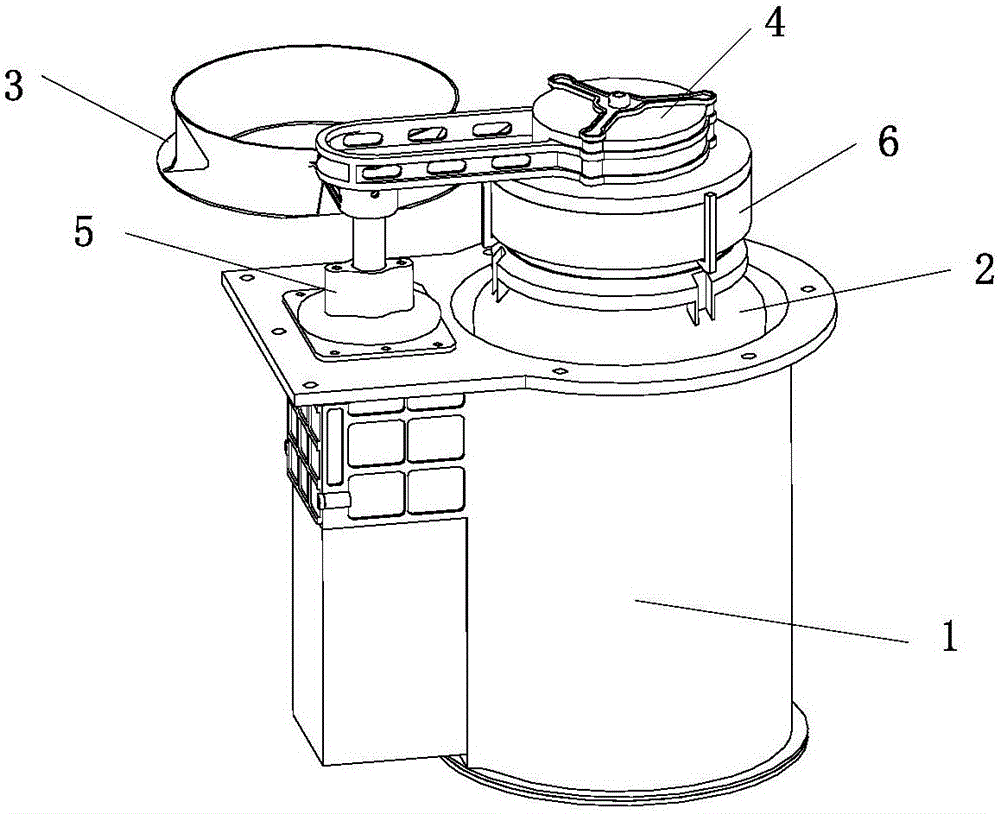

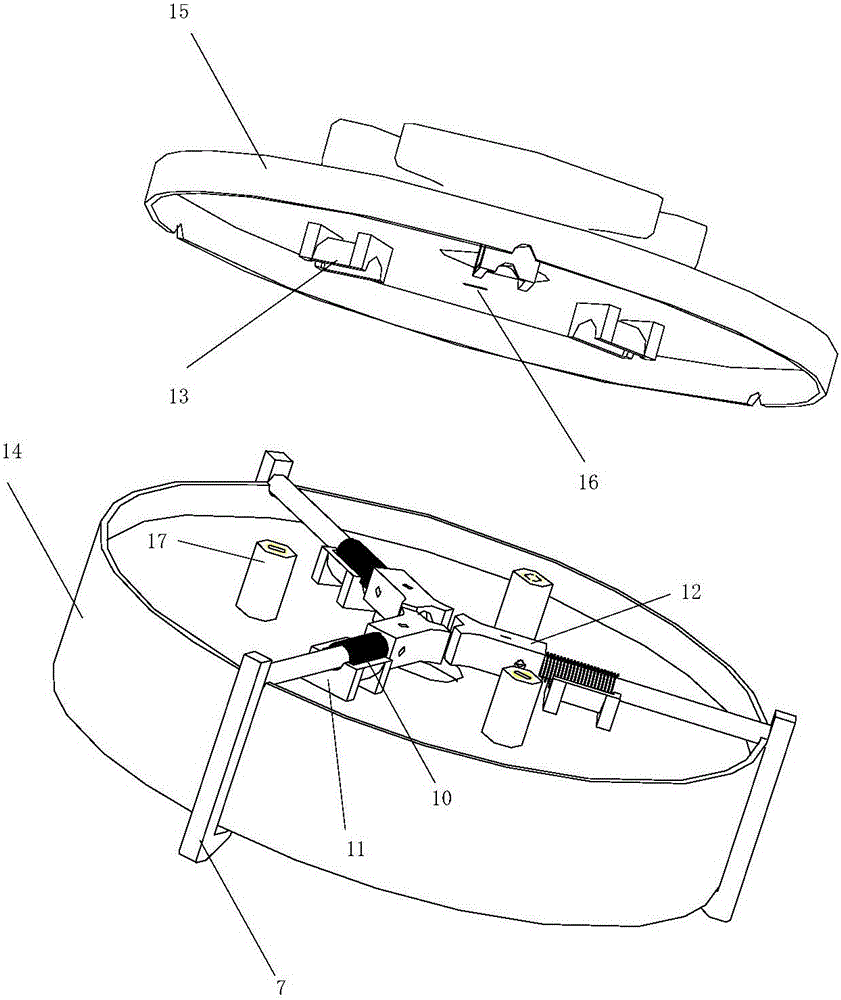

[0028] Embodiment 1. A primary packaging device for lunar surface sampling, such as figure 1 As shown, the device is composed of a body 1 , a sample container 2 , a sampling funnel 3 , a container cap packaging assembly 4 , a driving mechanism 5 and a container cap 6 .

[0029] The body 1 has two fixing spaces for fixing the sample container 2 and the driving mechanism 5 respectively.

[0030] The driving mechanism 5 has a driving shaft 23 for outputting driving force, and the driving shaft 23 realizes linear lifting motion and circular motion.

[0031] The stakeout funnel 3 is a flat-bottomed funnel, which is connected to the drive shaft through a funnel bracket.

[0032] The container cap packaging assembly 4 is connected to the drive shaft through the housing bracket 22 .

[0033] The container lid 6 is connected with the container lid packaging assembly 4 through a spring limiting mechanism.

[0034] When the drive shaft 23 moves upwards, it drives the container cap pac...

Embodiment 2

[0048] The device is composed of a packaging device body 1, a sample container assembly 2, a stakeout funnel 3, a container cover packaging assembly 4, a packaging device drive system 5, and a container cover 6. The main working process of the device is as follows: Figure 5 As shown, the description is as follows:

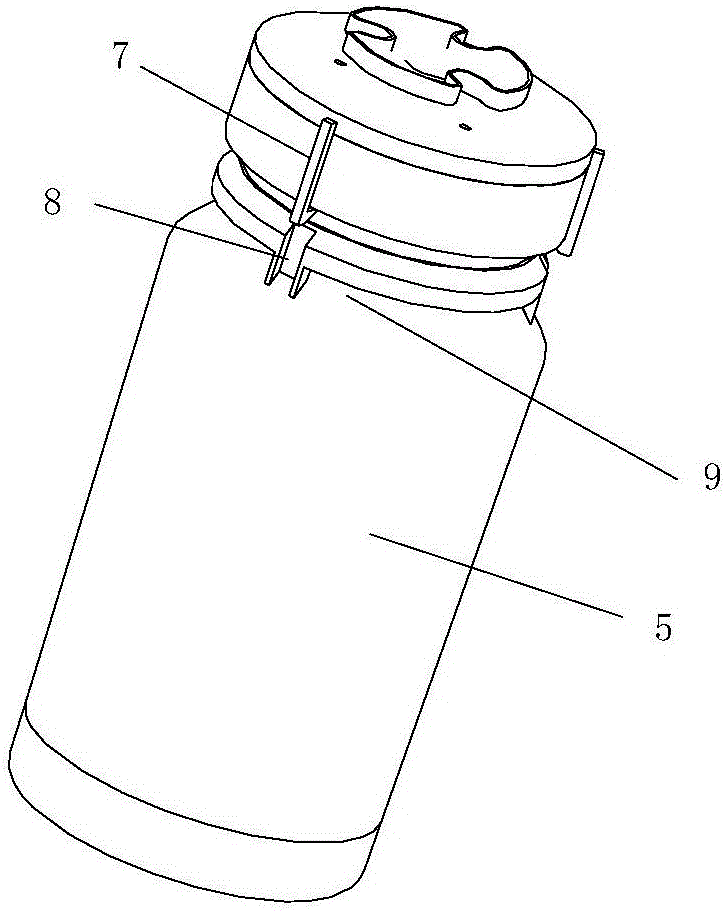

[0049] 1) In the launch stage: the drive system 5 presses the container cover 6 on the top of the sample container 6 with a certain pre-tightening force through the container cover packaging assembly 4, and at this time the container cover finger 7 is located in the container cover finger sliding groove 8, The container cover 5 only seals the sample container 6 to prevent pollutants from entering the sample container 6, but does not seal and lock it;

[0050] 2) Sampling preparation stage: the drive system 5 drives the drive shaft to perform linear upward movement, at this time the container cover finger 7 slides out from the container cover finger sliding groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com