Hemispherical candy packaging system

A packaging system, hemispherical technology, applied in the direction of conveyor belt packaging, etc., can solve the problems of consumption, large labor force, low work efficiency, etc., to avoid idling, improve work efficiency, and ensure smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

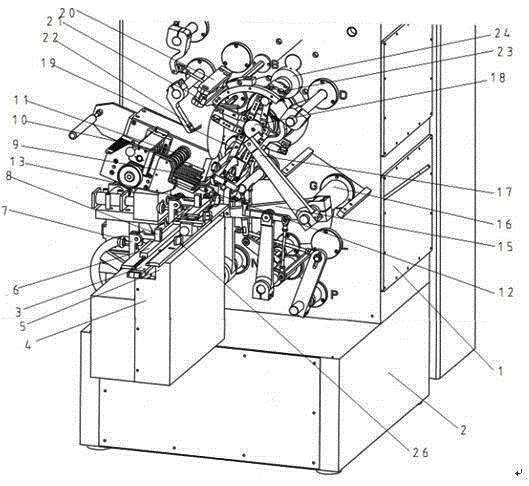

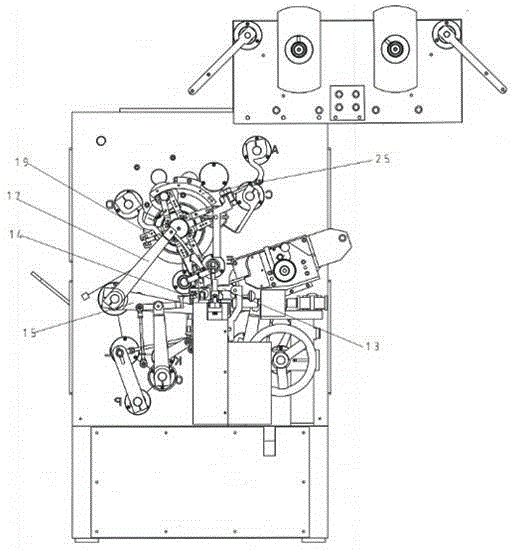

[0025] like figure 1 The shown hemispherical candy packaging system includes a packaging machine base and a conveying mechanism, a sugar feeding mechanism, a candy paper conveying mechanism, a rotating mechanism, a turning mechanism, a candy twisting mechanism and a candy blocking mechanism arranged in sequence along the candy conveying direction.

[0026] The packaging machine base is formed by a vertically arranged mounting seat 1 and a horizontally arranged base 2. Both the mounting seat 1 and the base 2 are installed in a rectangular parallelepiped. At the same time, the bottom end of the base 2 is also provided with four supports for supporting the base 2 foot.

[0027] The conveying mechanism is located at the feeding port end of the packaging machine base, and includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com