Intelligent packaging machine and control method thereof

A technology of intelligent packaging and rack, applied in the direction of packaging automatic control, packaging, transportation packaging, etc., can solve the problems of low work efficiency and large workload, and achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

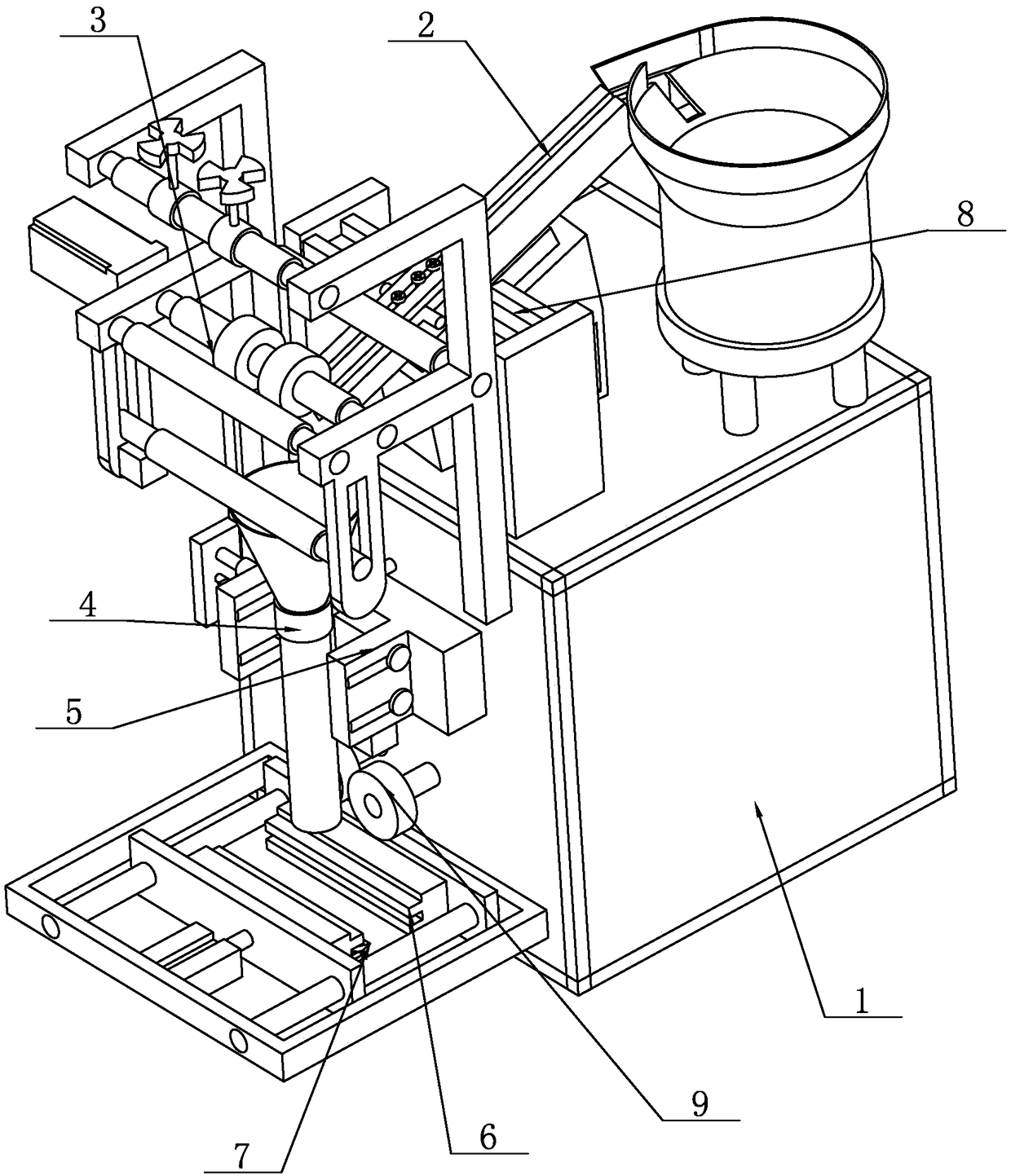

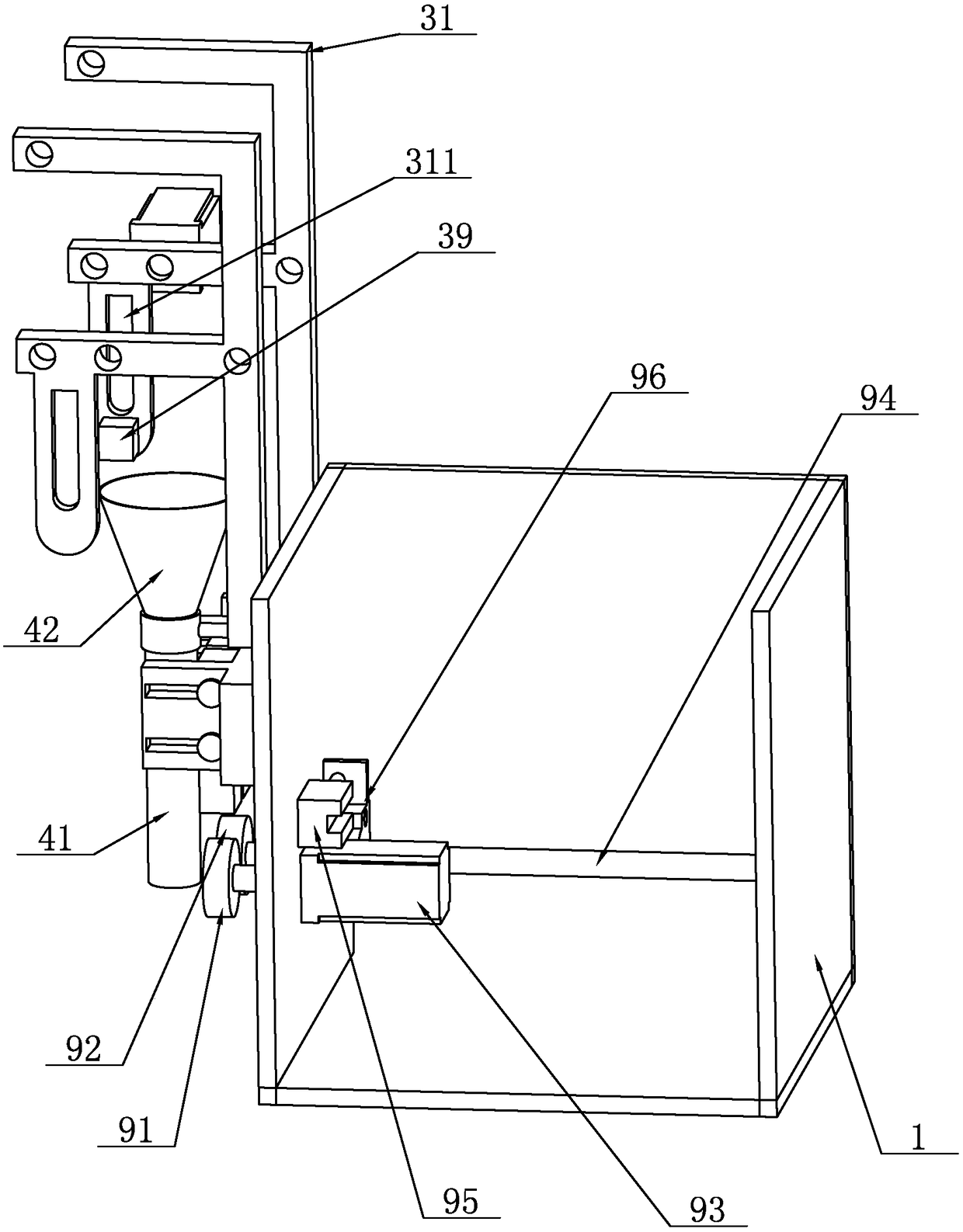

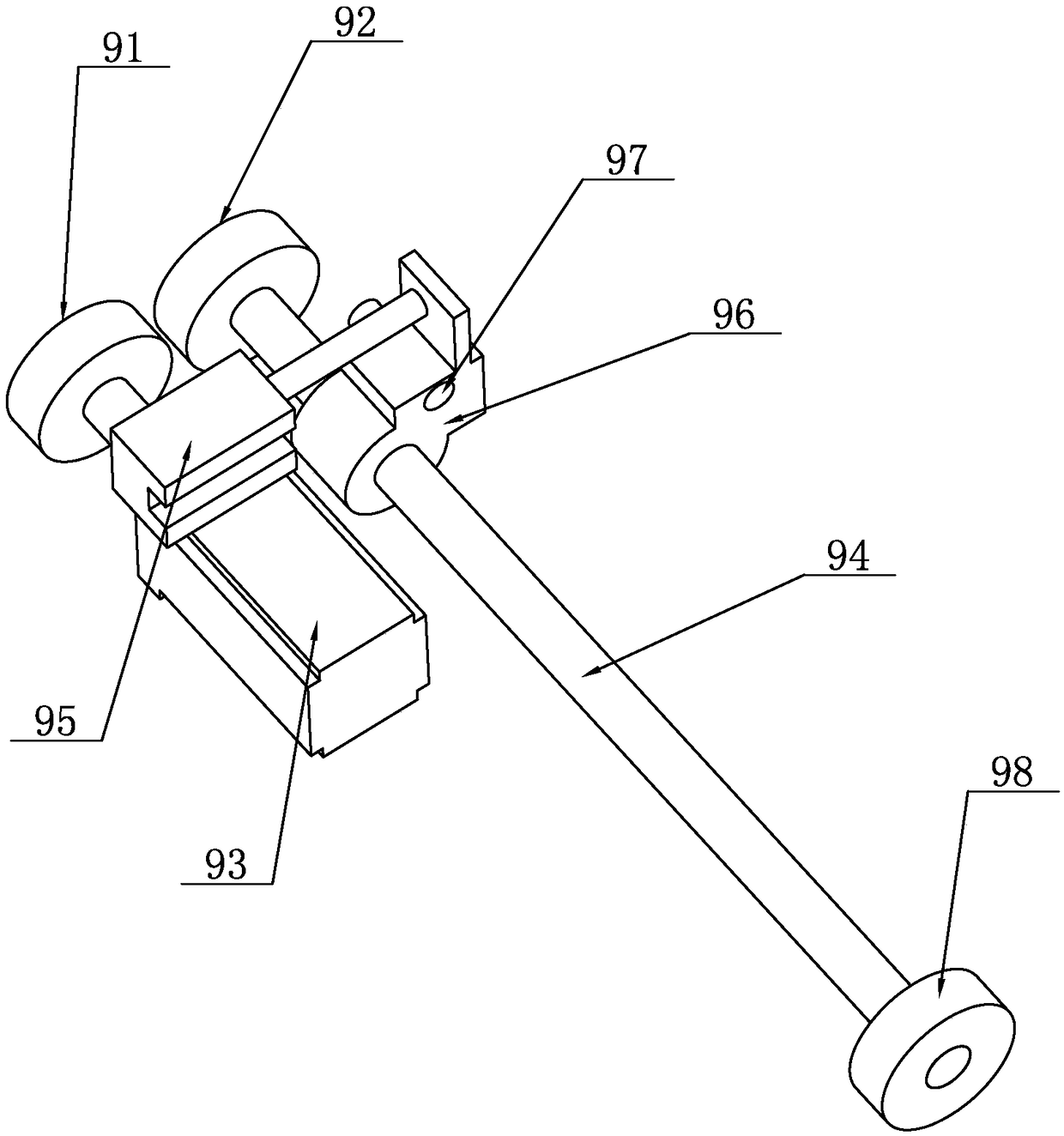

[0039] Such as Figure 1-Figure 9 As shown, an intelligent packaging machine includes a frame 1, and the frame 1 is provided with a screw feeding mechanism 2, a film feeding and conveying mechanism 3, a film bag forming mechanism 4, a longitudinal heat sealing mechanism 5, and a transverse heat sealing mechanism 6 , cutter mechanism 7 and controller 10, and this controller 10 can be used to control the normal operation of each mechanism, and film bag forming mechanism 4 comprises the bag former 41 that can curl film into cylindrical shape, and bag former 41 is along vertical The direction is fixed on the frame 1, the bag forming device 41 is provided with a channel 411, the top of the bag forming device 41 is provided with a hopper 42, the screw feeding mechanism 2 includes a feeding track 21 for transferring materials, and the outlet of the feeding track 21 The feed port extends to the hopper 42, the feeding track 21 is provided with a metering control assembly 8 that can con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com