Inner packing method for medical sterile gloves

A technology of inner packaging and gloves, which is applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of difficult to realize automatic packaging, long wearing time, complicated packaging, etc., and achieve low cost of packaging labor and consumables. The risk of pollution is small and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] According to the above methods, it can be understood that the present invention can be implemented in the following ways. refer to Figures 4a-4j Shown:

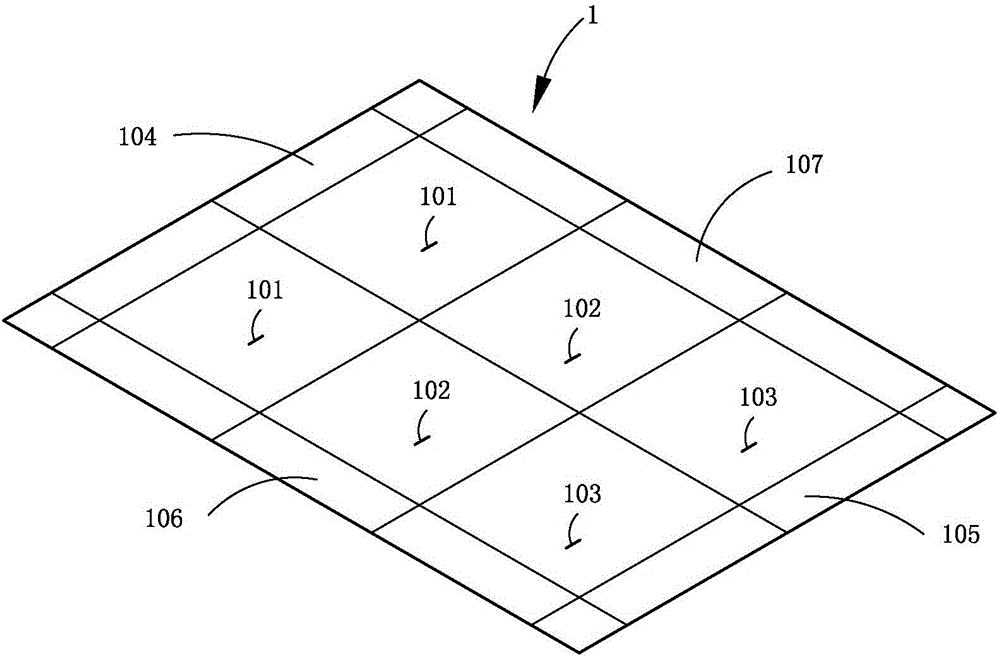

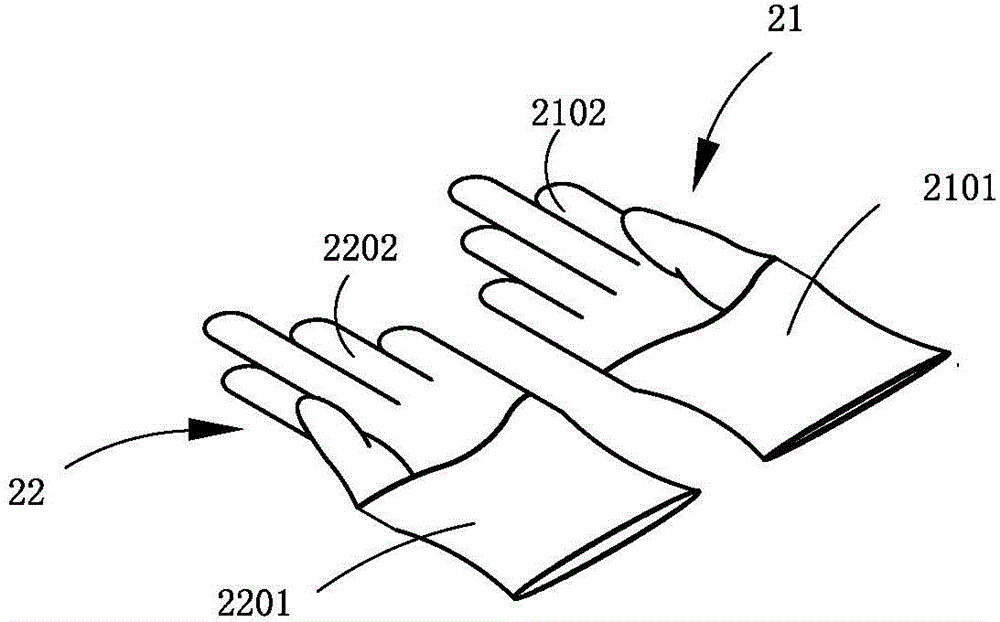

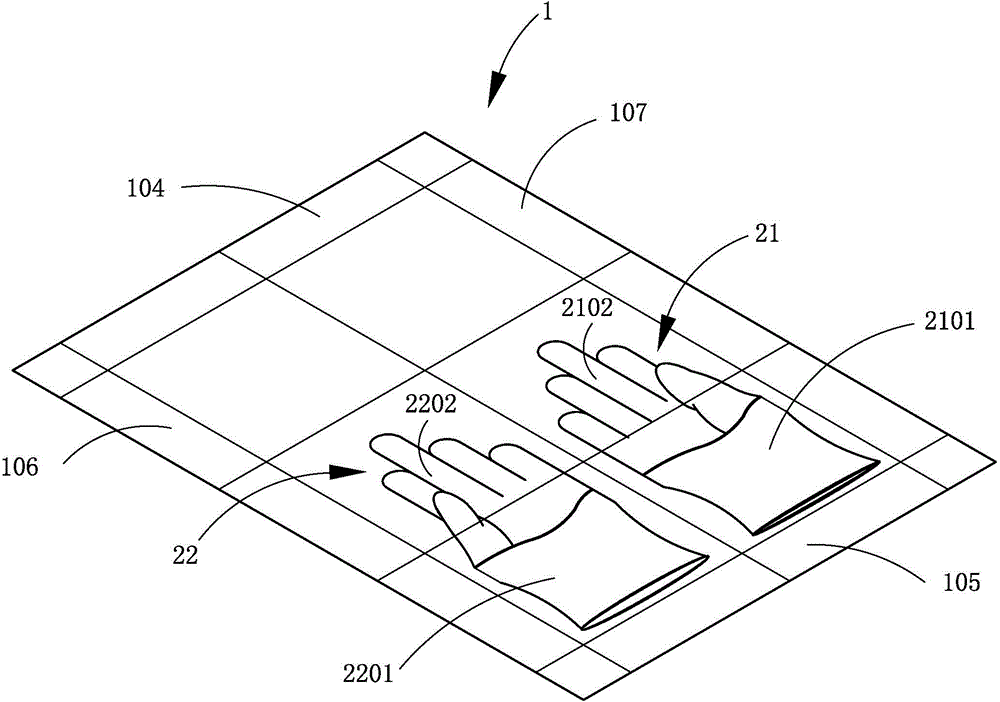

[0046] The first step is to provide a lining paper 1 and spread the lining paper 1 flat. The lining paper 1 has a rectangular structure. After laying the lining paper 1, it is roughly divided into three parts. Front part 101, inner lining paper middle part 102 and inner lining paper rear part 103; provide a pair of cuffed gloves, are respectively left hand glove 22 and right hand glove 21, and the glove palm portion of left hand glove 22 and right hand glove 21 is placed inside On the first surface of the lining paper 1, the little fingers of the left-hand glove 22 and the right-hand glove 21 are close to each other and in a symmetrical state; the specific position of a pair of cuffed gloves placed on the lining paper 1 is: the wrist of the left-hand glove 22 is placed on the lining paper The left side of the rear p...

Embodiment 2

[0055] According to the above methods, it can be understood that the present invention can be implemented in the following ways. refer to Figures 5a-5j Shown:

[0056] The first step is to provide a lining paper 1 and spread the lining paper 1 flat. The lining paper 1 has a rectangular structure. After laying the lining paper 1, it is roughly divided into three parts. Front part 101, inner lining paper middle part 102 and inner lining paper rear part 103; provide a pair of cuffed gloves, are respectively left hand glove 22 and right hand glove 21, and the glove palm portion of left hand glove 22 and right hand glove 21 is placed inside On the first surface of the lining paper 1, the little fingers of the left-hand glove 22 and the right-hand glove 21 are close to each other and in a symmetrical state; the specific position of a pair of cuffed gloves placed on the lining paper 1 is: the wrist of the left-hand glove 22 is placed on the lining paper The left side of the rear p...

Embodiment 3

[0065] According to the above methods, it can be understood that the present invention can be implemented in the following ways. refer to Figures 6a-6j Shown:

[0066]The first step is to provide a lining paper 1 and spread the lining paper 1 flat. The lining paper 1 has a rectangular structure. After laying the lining paper 1, it is roughly divided into three parts. Front part 101, inner lining paper middle part 102 and inner lining paper rear part 103; provide a pair of cuffed gloves, are respectively left hand glove 22 and right hand glove 21, and the glove palm portion of left hand glove 22 and right hand glove 21 is placed inside On the first surface of the lining paper 1, the little fingers of the left-hand glove 22 and the right-hand glove 21 are close to each other and in a symmetrical state; the specific position of a pair of cuffed gloves placed on the lining paper 1 is: the wrist of the left-hand glove 22 is placed on the lining paper The left side of the rear pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com