Crystal oscillator automatic packaging machine

An automatic packaging machine, crystal oscillator technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of time-consuming and laborious, damage to the appearance of the crystal oscillator, and increase the packaging operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

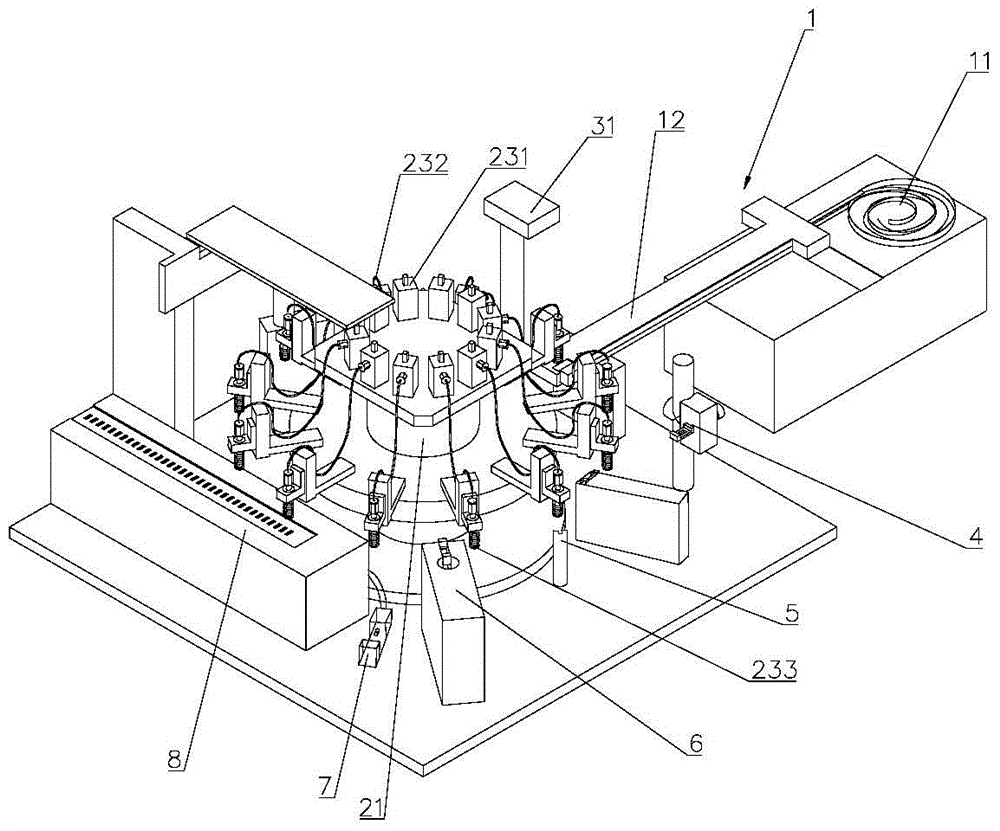

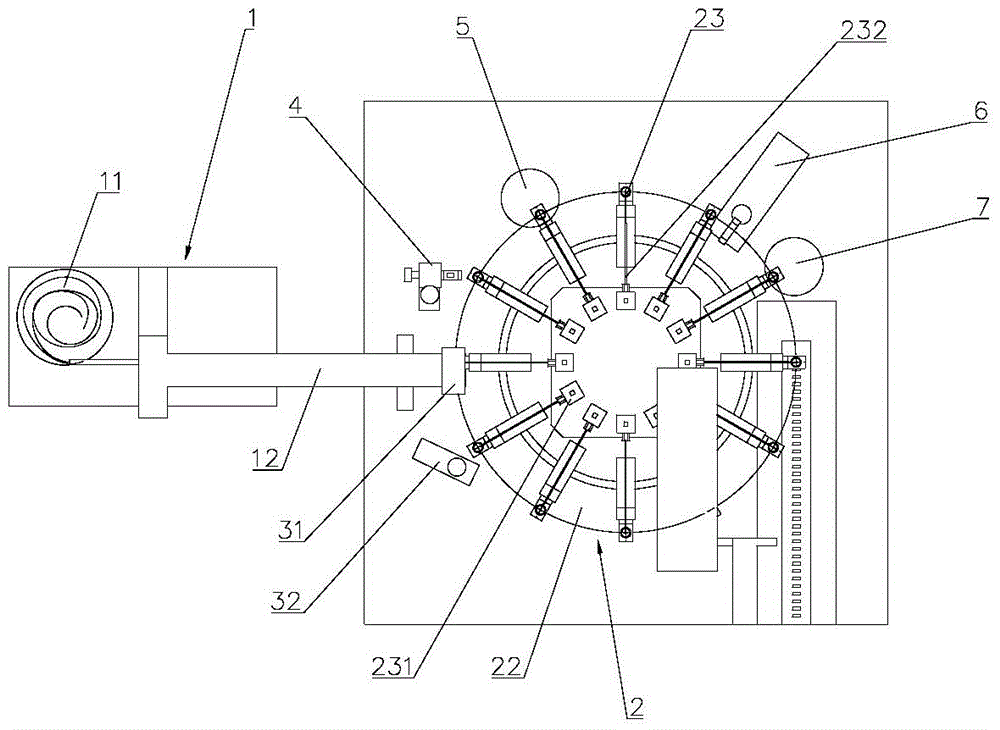

[0016] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0017] The most critical idea of the present invention is: through the cooperation of feeding mechanism, transmission mechanism, detection mechanism, rejecting mechanism, flipping mechanism, position correction mechanism, counting mechanism, packaging mechanism and controller, the crystal oscillators are all face-up. The entering packaging mechanism realizes the automatic packaging of the crystal oscillator.

[0018] Please refer to figure 1 and figure 2 , crystal vibration automatic packaging machine, including feeding mechanism 1, transmission mechanism 2, detection mechanism, rejecting mechanism 4, turning mechanism 5, position correction mechanism 6, counting mechanism 7, packaging mechanism 8 and controller, the controller and feeding Mechanism 1, tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com