Automatic packing machine for all-model aluminium products

An automatic packaging machine and aluminum material technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost of machinery, many overlapping parts of packaging paper, and difficulty in promotion, so as to save manpower, improve efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

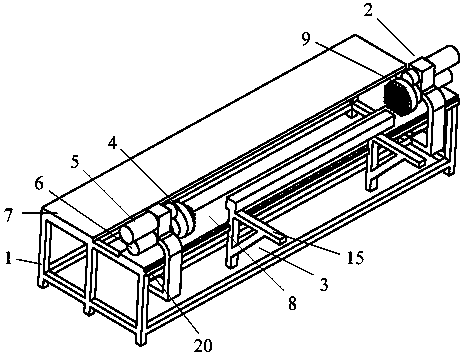

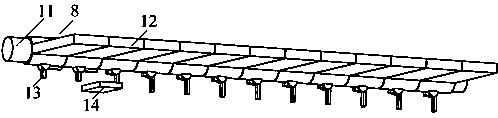

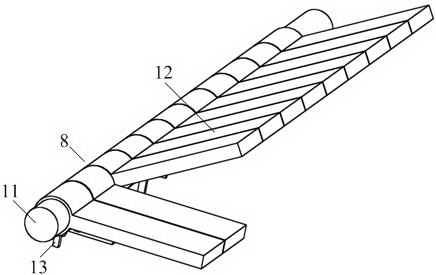

[0026] Such as figure 1 As shown, the first embodiment of the present invention provides a full-type automatic packaging machine for aluminum materials, including a frame 1, a packaging mechanism 2 arranged on the frame 1, and a packaging mechanism for transferring aluminum materials to the packaging mechanism The feeding mechanism 3 of 2; the packaging mechanism 2 includes a universal gripper 4 symmetrically arranged at both ends of the frame 1 for fixing the aluminum material, and the universal gripper 4 can rotate under the drive of the rotating motor 5 and Driven by the pneumatic push rod 6, it expands and contracts back and forth; the frame 1 is provided with a packaging platform 7, and the side of the packaging platform 7 corresponding to the universal gripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com