Automatic producing and packaging unit for stainless steel pipes

A packaging unit, stainless steel technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to automatically adjust the position of the welding seam, misalignment between the welding seam and the welding torch, and burrs at the cutting of the sheet, etc. Achieve the effect of good polishing effect, high welding quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

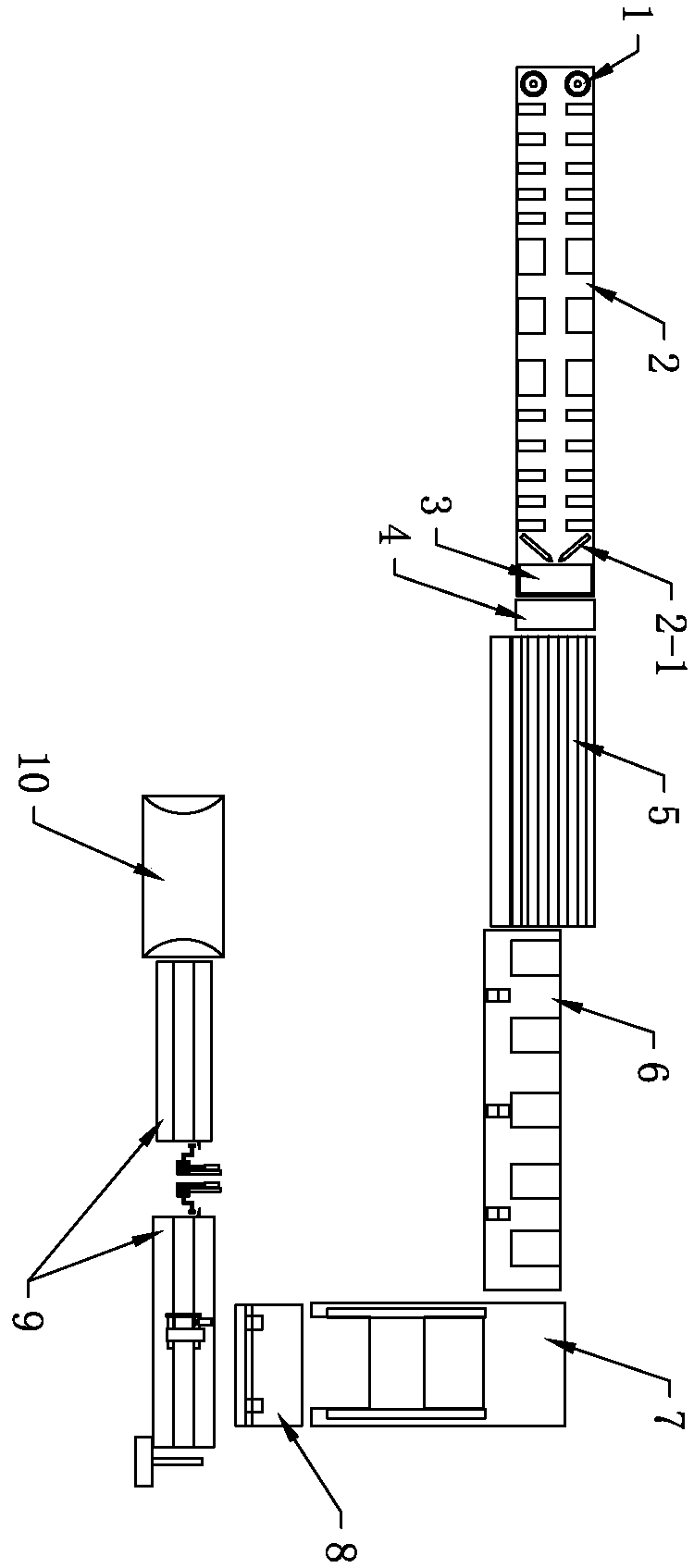

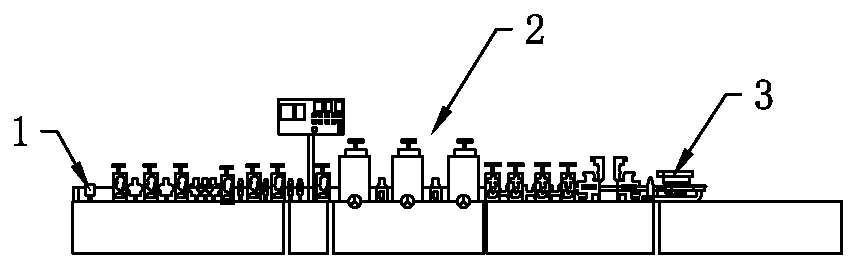

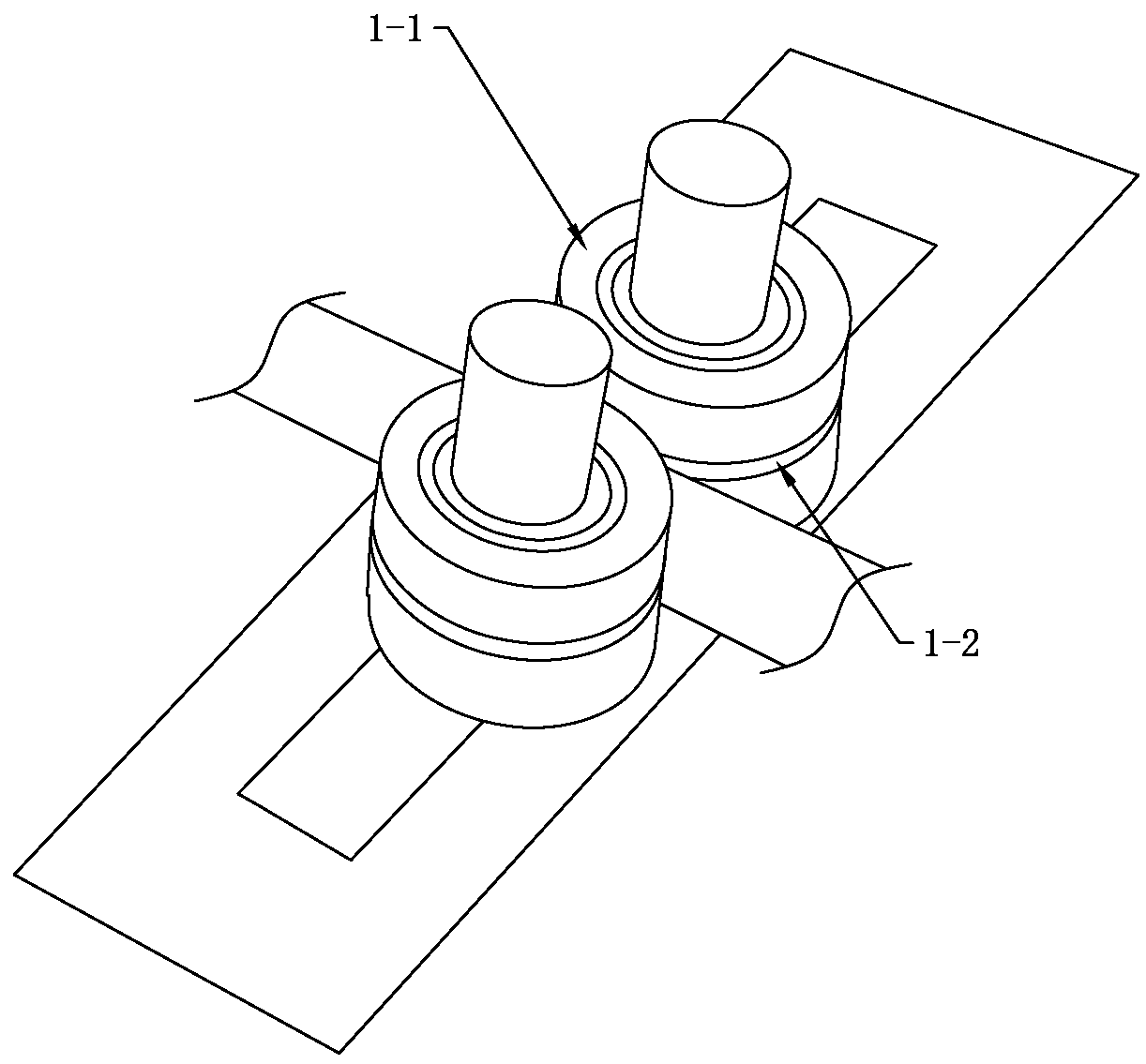

[0069] see Figures 1 to 13 , the stainless steel pipe automatic production and packaging unit of the present embodiment is provided with pipe making machine 2, pipe cutting machine 4, polishing machine 6 and steel pipe packaging machine 9 in sequence, pipe making machine 2, pipe cutting machine 4, polishing machine 6 and steel pipe packaging machine 9 are all controlled by the central controller. Wherein, the feeding side of the pipe making machine 2 is equipped with a sheet material side grinding device, and the sheet material side grinding device includes two paired grinding wheels 1-1, and the cross section of the grinding groove 1-2 is a It is trapezoidal with a large outside and a small inside, and the width of the inner bottom groove of the grinding groove 1-2 is the same as the thickness of the polished sheet. Each grinding wheel 1-1 is rotatably mounted on the wheel shaft, and the side surface of the grinding wheel 1-1 is provided with an annular grinding groove 1-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com