Modular panty-hose whole process automatic packing production line and working method thereof

A packaging production line, fully automatic technology, applied in the field of high-end packaging equipment, can solve problems such as transportation difficulties, time-consuming commissioning, troublesome installation, etc., and achieve the effects of improving operational reliability, flexible working methods, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

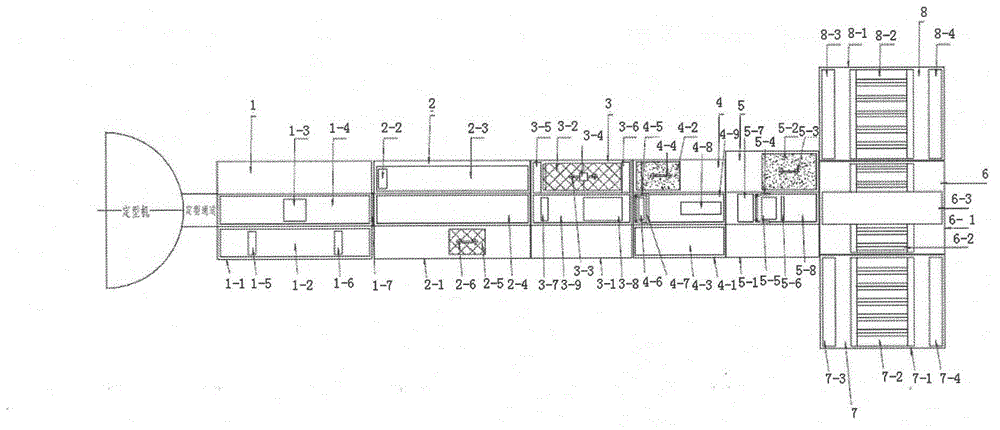

[0044] Such as figure 1 Shown is the schematic diagram of the composition of the whole automatic packaging production line of the modularized pantyhose of the present invention, including: a detection module 1, a folding module 2, an outer packaging module 3, a bagging module 4, a packaging module 5, a boxing module 6, and a boxing module 7 And sealing module 8.

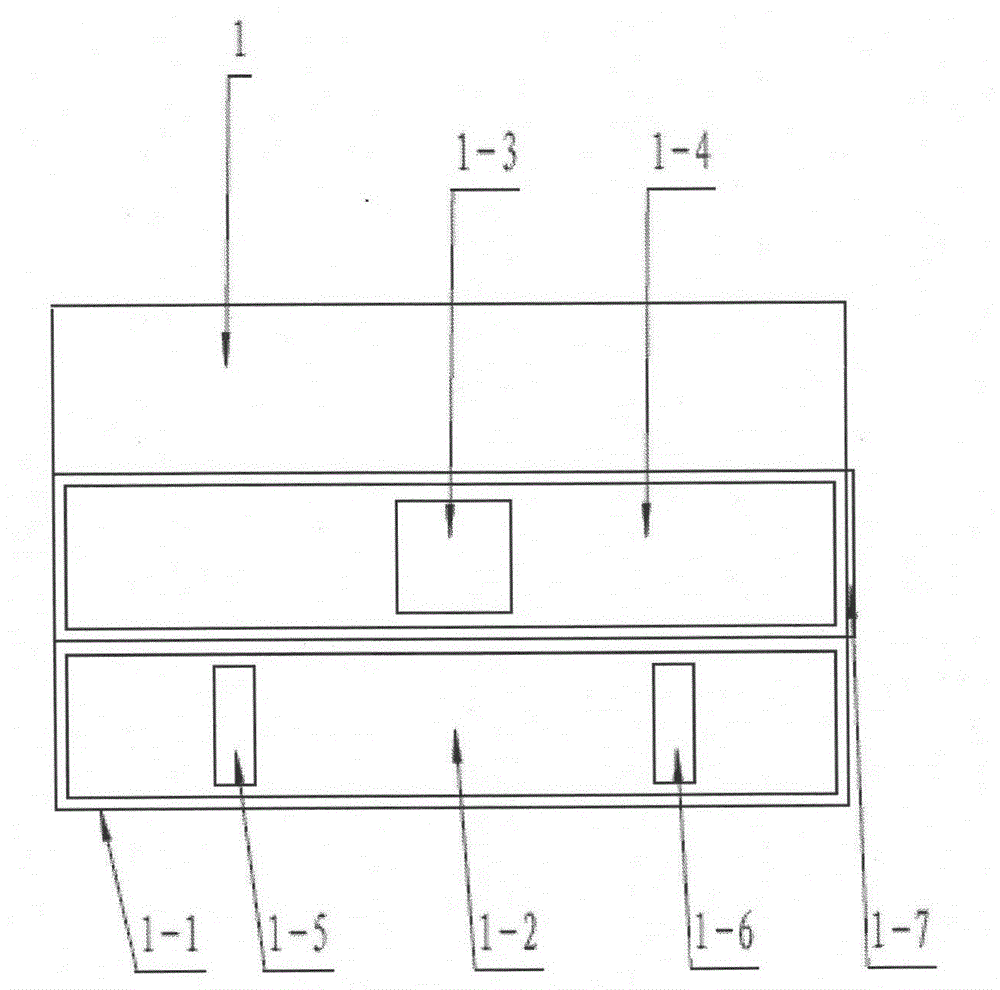

[0045] Such as figure 2 Shown is a schematic diagram of the composition of the detection module 1, which completes the quality inspection of pantyhose after finalizing and before packaging, including: detection module cabinet 1-1, and the control system of the automatic packaging production line is installed in the detection module cabinet 1-1 And be provided with defective pantyhose storage area 1-2, be provided with detection industrial camera 1-3, transmission mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com