Titanium dioxide automatic packaging process and dedicated system thereof

A technology of automatic packaging and titanium dioxide, which is applied in the direction of packaging, transportation and packaging, and the type of packaging items, to achieve the effect of increasing production, improving automation level, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

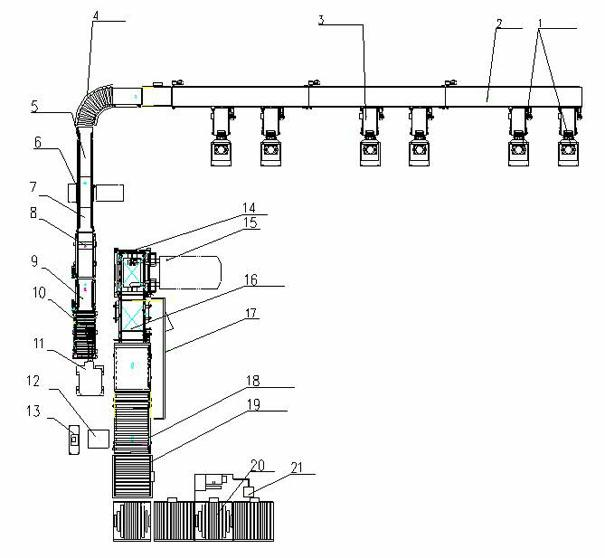

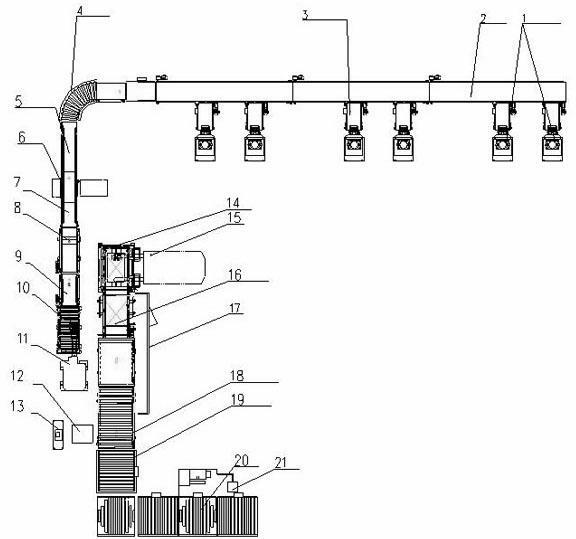

[0019] As shown in Figure 1, the special automatic packaging system for titanium dioxide of the present invention is a plurality of production lines, and each production line comprises: a packaging machine 1, a re-inspection machine 5, a sorting machine 6, a shaping machine 8, Palletizing manipulator 11, tonnage re-inspection scale 19, winding machine 20 and inkjet printer 21. There are also a complete set of equipment, accessories and auxiliary facilities that can ensure the normal and automatic operation of the production line, such as the conveying system control cabinet 13 and the guardrail 17;

[0020] Conveyors include the slow-stop conveyor 3 near the packaging machine 1, the main conveyor 2, the corner conveyor 4 between the packaging machine 1 and the re-inspection machine 5, and the climbing conveyor between the sorting machine 6 and the shaping machine 8 The slow-stop conveyor 9 between the machine 7, the shaping machine 8 and the stacking manipulator 11, the bag-ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com