An automatic cocoon cutting and separating device

A separation device and silkworm cocoon technology, applied in the directions of transportation and packaging, conveyor objects, metal processing, etc., can solve the problems of increased production costs of silkworm seeds, operators being cut, and labor-intensive, etc., to achieve compact structure and improve efficiency. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

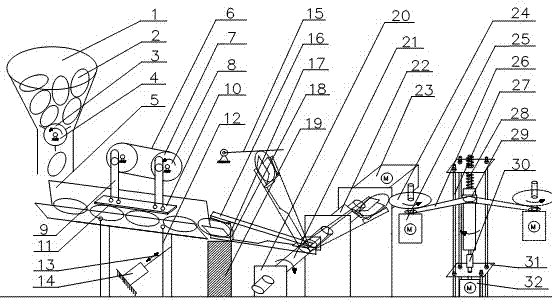

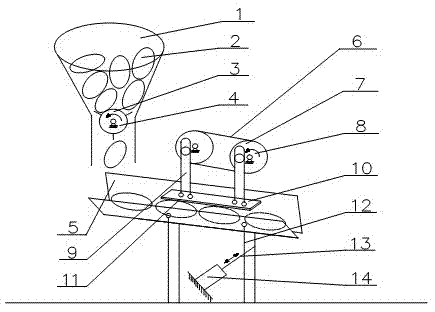

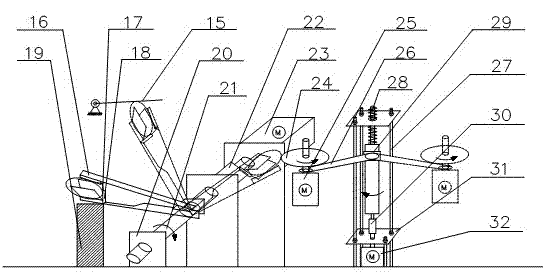

[0019] The specific structure of the present invention is provided by the following detailed description and accompanying drawings.

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as figure 1 As shown, the cocoon automatic cutting and separating device of the present invention mainly consists of an automatic cocoon arranging and conveying device, an automatic cocoon cutting and a silkworm shell and silkworm chrysalis separating device. The automatic arrangement and conveying device for silkworm cocoons mainly includes a hopper 1 for placing silkworm cocoons 2, a cocoon dial 4 fixed on the first motor 3, two smooth splints 5, a belt 6, and an eccentric wheel 8 fixed on the second motor 7 , guide rail 9, cocoon pressing plate 10, rubber gasket 11, spring steel sheets 12, 13 and electromagnet 14 are formed;

[0022] The cocoon automatic cutting and separating device includes a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com