Method and system for removing slitter edges of sheet products by die cutting processing

A sheet and die-cutting technology, applied in metal processing and other directions, can solve the problems of unclean removal, low efficiency, and damage to finished products, and achieve the effect of improving production efficiency and finished product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

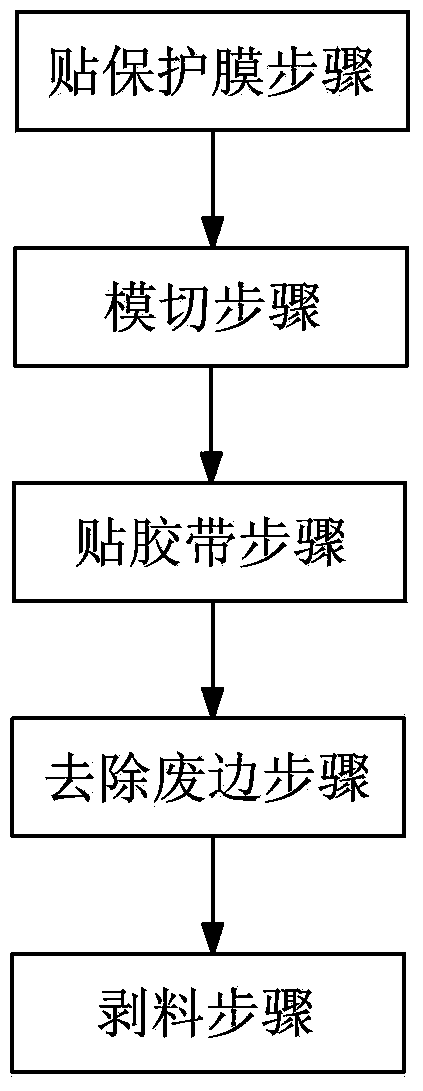

[0028] Such as figure 1 As shown, the present invention provides a kind of sheet material product die-cutting processing and removes waste side method, and it comprises the steps:

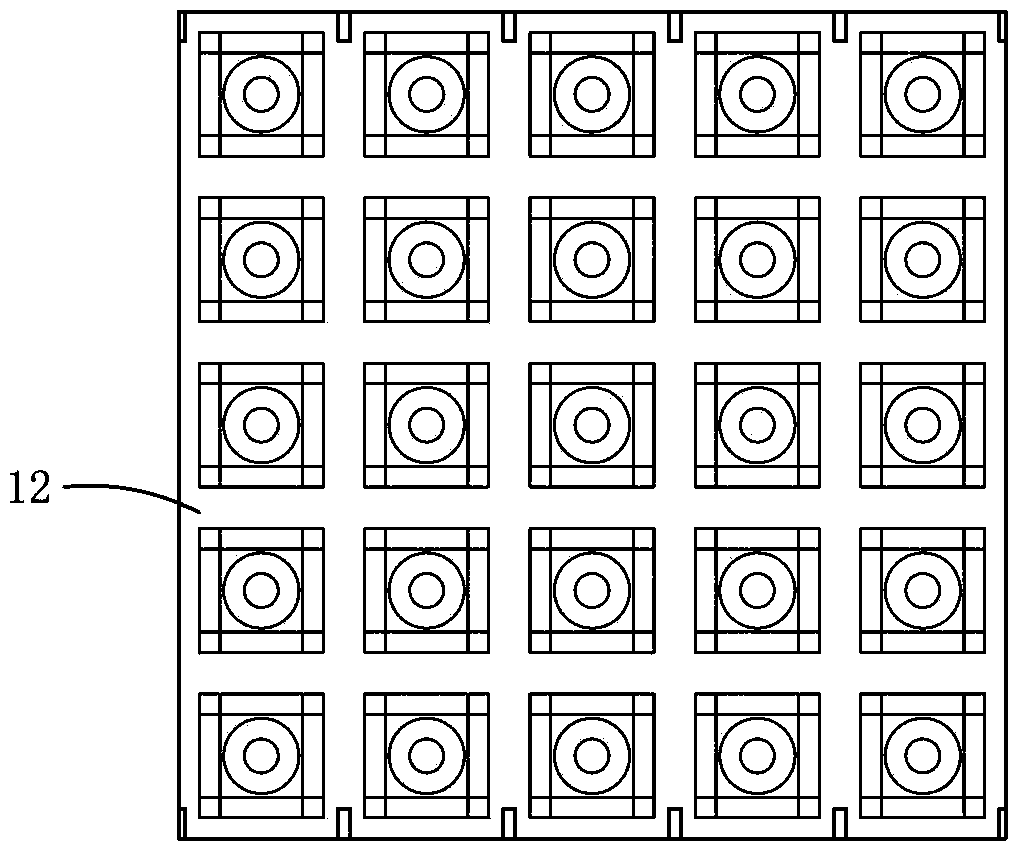

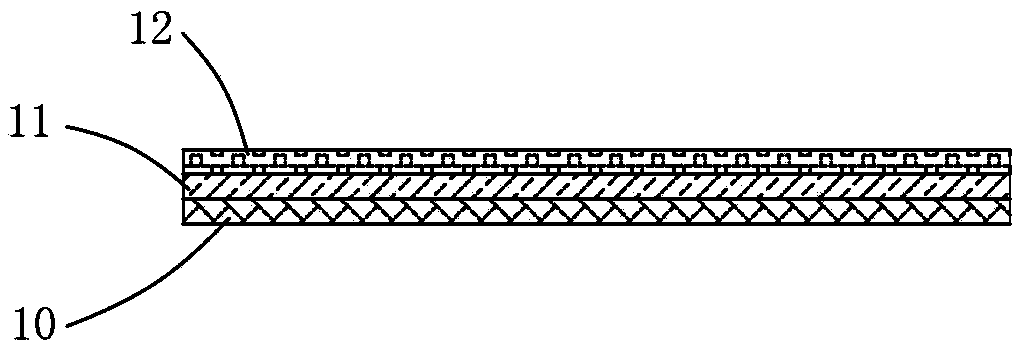

[0029] Paste the protective film step, stick the sheet material 12 (such as figure 2 and image 3 As shown), the outer surface of the release paper 10 is pasted on the protective film 14 that is tape-shaped and has an adhesive surface (such as Figure 4 and Figure 5 shown), and then collected into rolls for later use. Preferably, the sheet material 12 is pasted on the protective film 14 by manual lamination or automatic lamination of roll-to-roll laminating machines. The sheet with release paper 10 att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com