Material edge detecting method of tooling

An end picker and material grouping technology, applied in the field of robotics, can solve the problems of large amount of calculation, complex calculation, not simple and direct enough, etc., and achieve the effect of high operation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

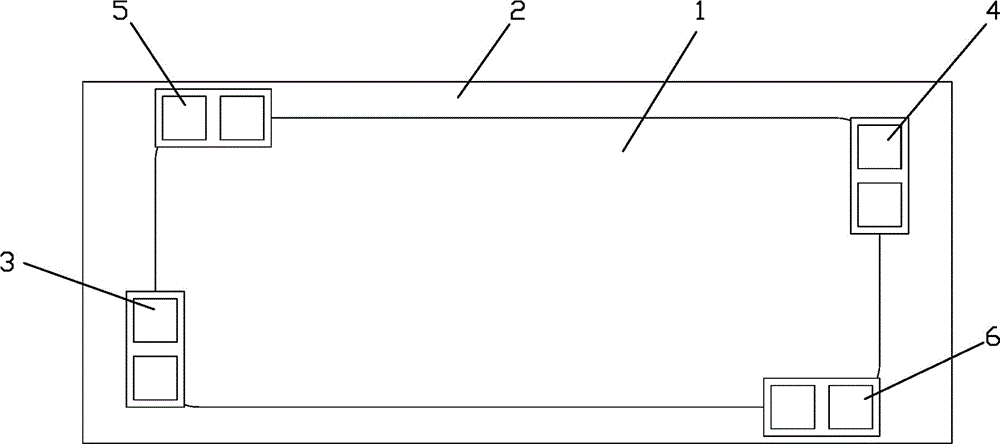

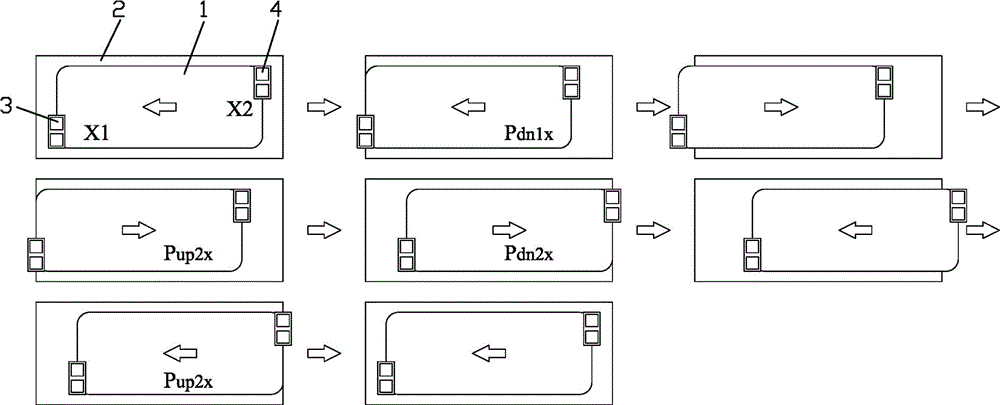

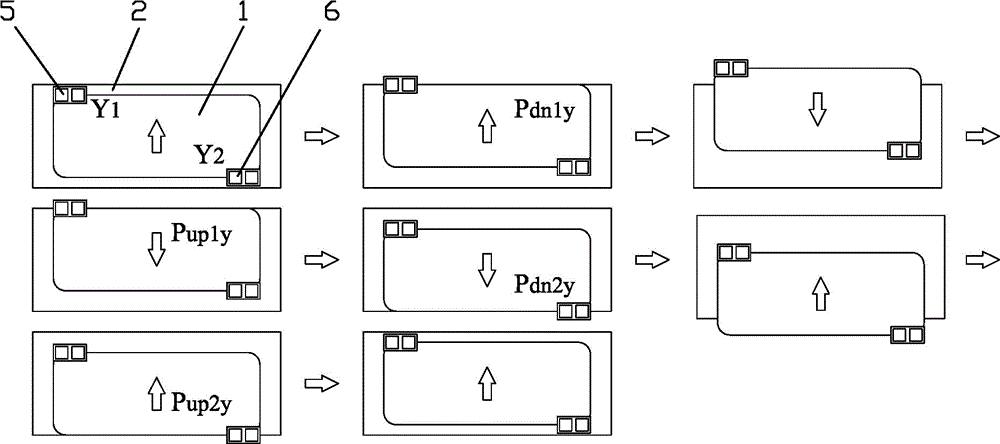

[0026] see Figure 1 to Figure 4 , the end picker of the present invention detects the edge of the group of materials, a group of edge sensors are respectively arranged in the X and Y directions of the end picker 1 to detect the edge position of the group material 2, and each group of edge detection The sensor has two sensors 3 to 6, which are installed at the diagonal position of the end picker 1; the edge measuring sensor is a photoelectric sensor, and its measuring direction, transmitting and receiving direction are perpendicular to the measuring side; The two directions of X and Y reciprocate at least once in order to obtain the position of the edge of the assembly 2, and the reciprocating stroke is ±50mm~±100mm; the lower part of the end picker 1 connected to the robot flange is provided with two end pickers for calibration. 1 Two sets of calibration sensors 7 for the positions of edge sensors 3-6.

[0027] After the edge measuring sensors 3 and 4 (X1, X2) reciprocate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com