Injection molding machine device comprising robot arm

A technology for injection molding machines and robotic hands, applied in the field of injection molding machine devices including robotic hands, can solve problems such as difficult clamping, waste of space resources, and large space occupation, and achieve accurate positioning and good stability for picking and blanking , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

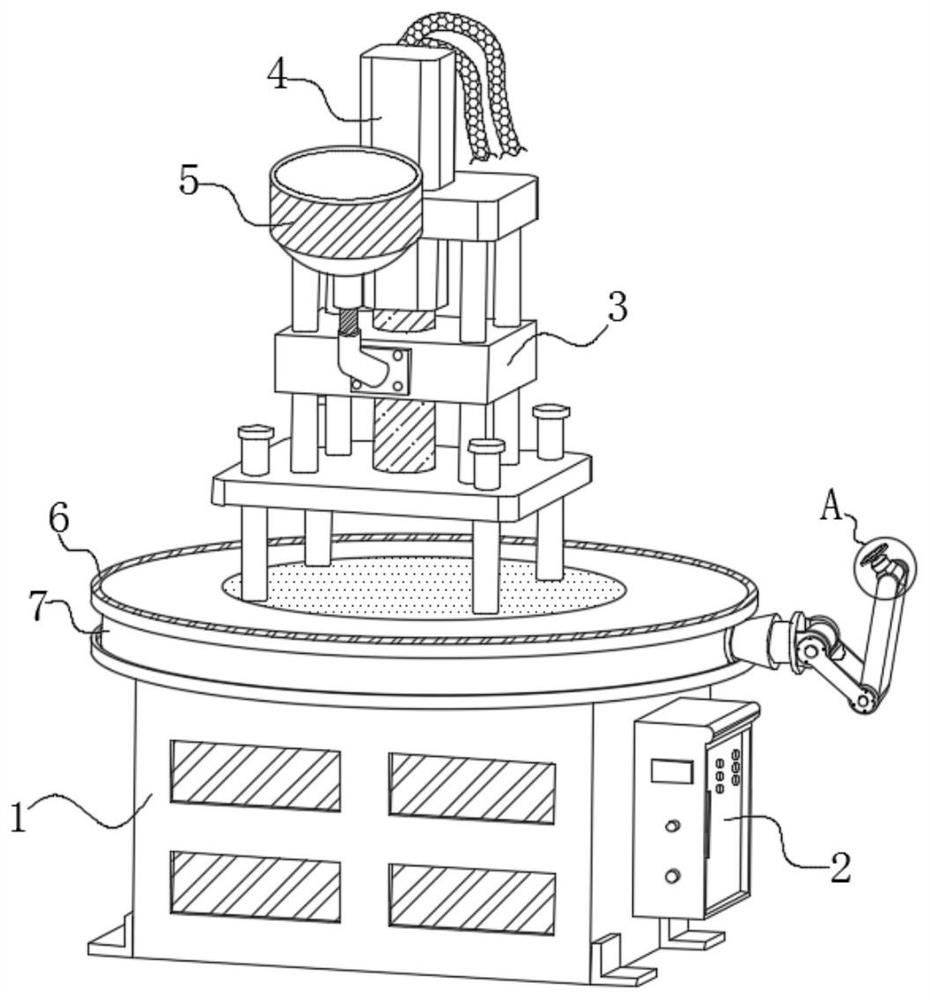

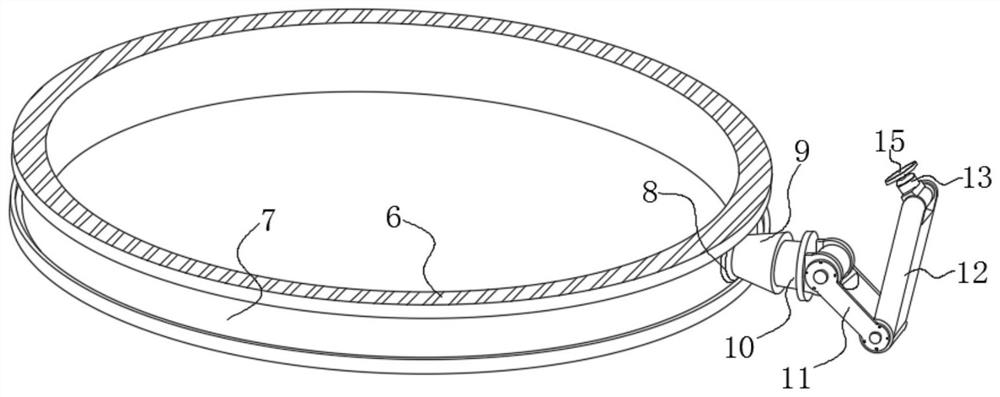

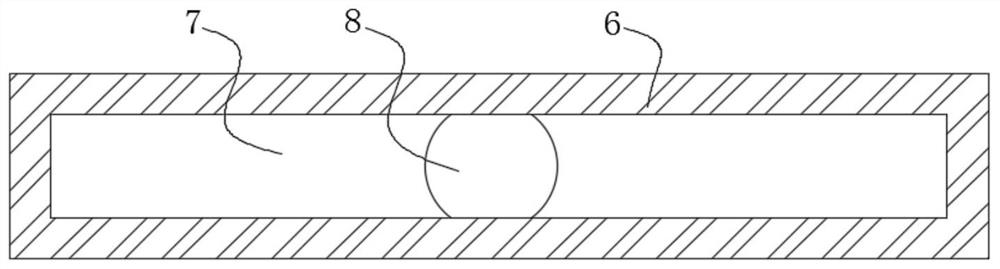

[0027] Example: such as Figure 1-6 As shown, an injection molding machine device including a robotic arm of the present invention includes an injection molding station 1, a control box 2 is provided on the side surface of the injection molding station 1, an injection molding mechanism 3 is fixedly connected to the upper surface of the injection molding station 1, and the top of the injection molding mechanism 3 A hydraulic mechanism 4 is provided, and the outer surface of the injection molding mechanism 3 is fixedly connected with a feeding port 5. The side surface of the injection molding table 1 is located above the control box 2 and is fixedly connected with a slide plate 6. The surface of the slide plate 6 is provided with a chute 7. The chute The inside of 7 is slidingly connected with a circular slide 8, the outer surface of the support shaft 9 is fixedly connected with the support shaft 9, the outer surface of the support shaft 9 is rotatably connected with the shaft bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com