Pulling rope release system of small multi-shaft unmanned aerial vehicle

A technology of unmanned aerial vehicle and traction rope, which is applied in the field of small multi-axis unmanned aerial vehicle traction rope deployment system, can solve the problems of low degree of mechanized installation, hidden dangers of personal safety, and insufficient scheme, so as to improve the operation accuracy and construction effect, reducing the intensity of manual labor, and controlling the shooting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

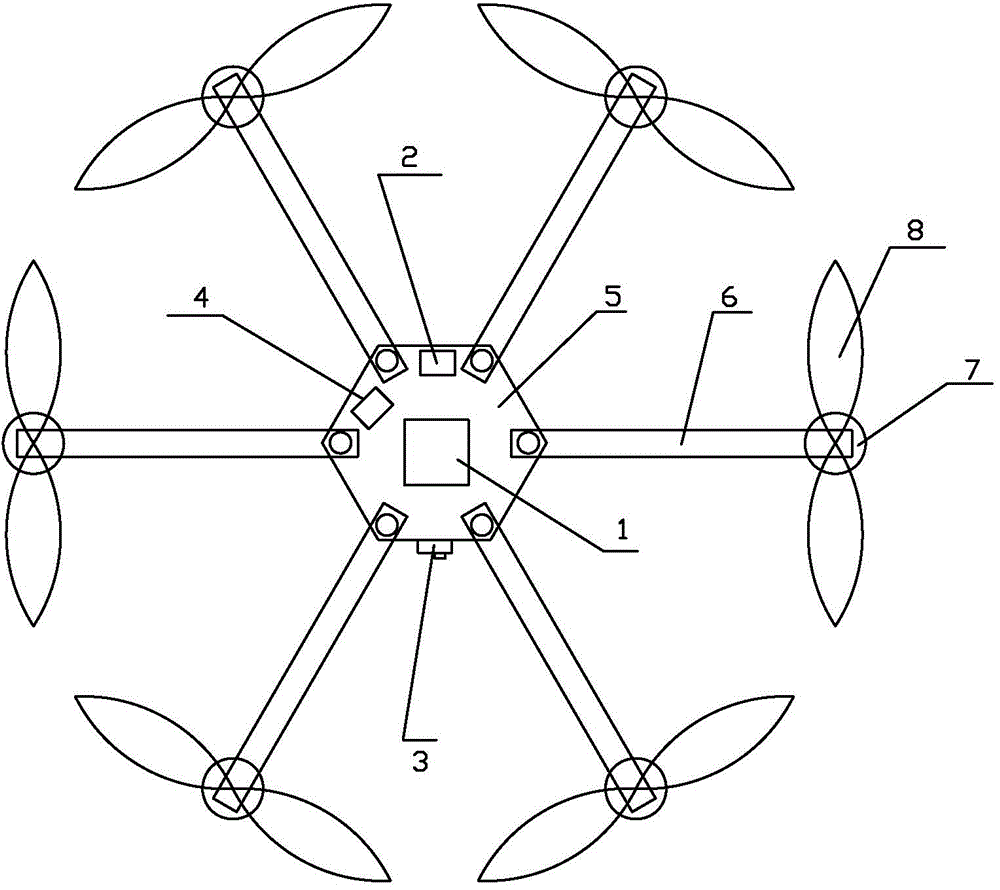

[0021] Examples, see figure 1 As shown, a kind of small-sized multi-axis unmanned aerial vehicle traction rope deployment system of the present invention comprises:

[0022] Multi-axis UAV, the multi-axis UAV is equipped with a control system 1 that can wirelessly receive remote control commands issued by the ground station and control the flight of the multi-axis UAV. The control system 1 specifically includes a GPS navigator, a receiving antenna, a power supply (The power supply is specifically a battery) and the master controller, the master controller receives the remote control command sent by the ground station through the receiving antenna;

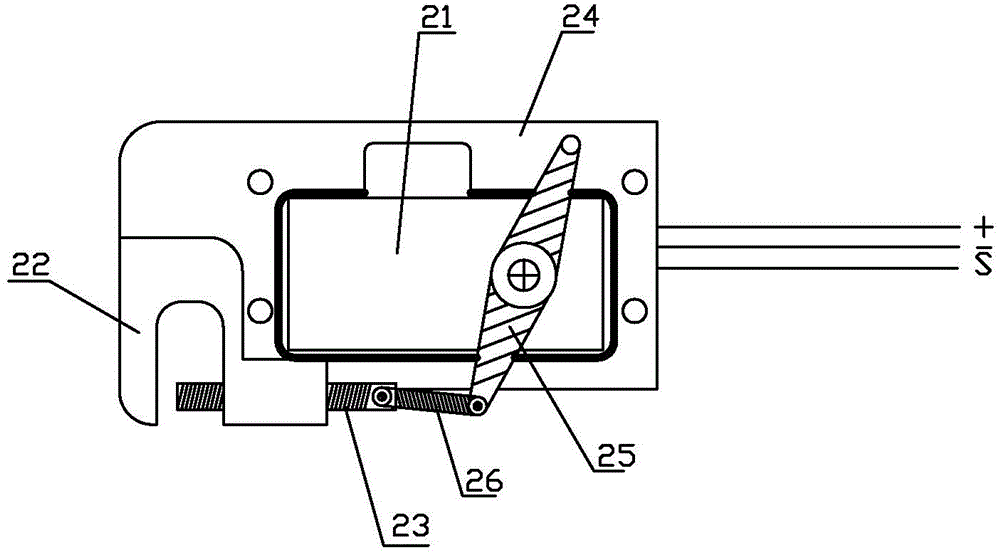

[0023] Lead wire unwinding device, the lead wire unwinding device includes a pay-off frame (not shown in the figure), a lead decoupling controller 2, a pay-off wheel is movable on the pay-off frame, and a traction rope is wound on the pay-off wheel. The pay-off frame is arranged on the ground, and the lead wire decoupling controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com