Industrial robot variable parameter stiffness identification and modeling method

An industrial robot and modeling method technology, which is applied in the field of variable parameter stiffness identification and modeling of industrial robots, can solve the problems of unsatisfactory robot stiffness modeling accuracy and low applicability in the whole working space, so as to improve operation accuracy and improve Predictability, Workload Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

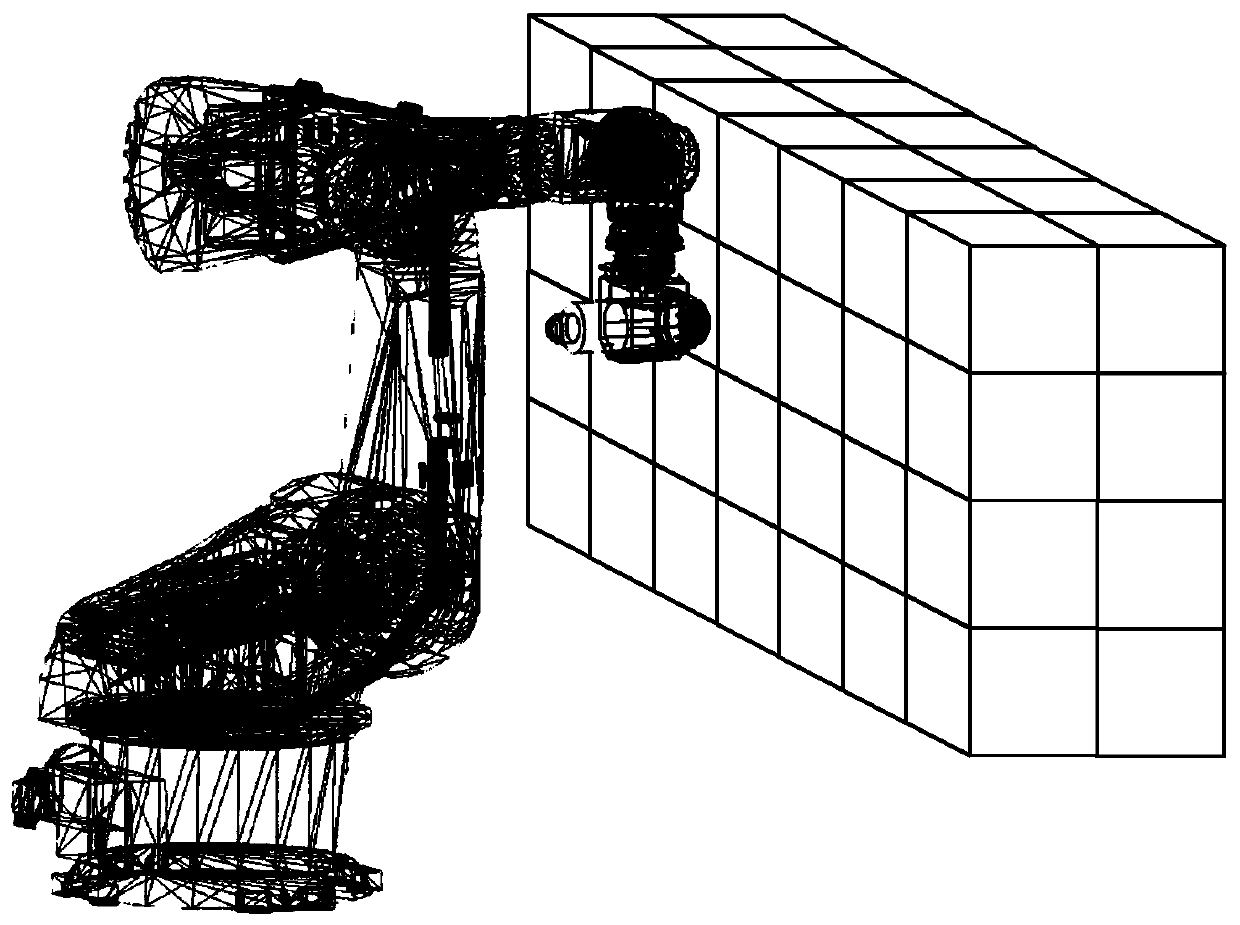

[0034] The stiffness identification equipment required by the technical solution of the present invention mainly includes: industrial robots, laser trackers (or other positioning acquisition sensors), six-dimensional force sensors, and the like.

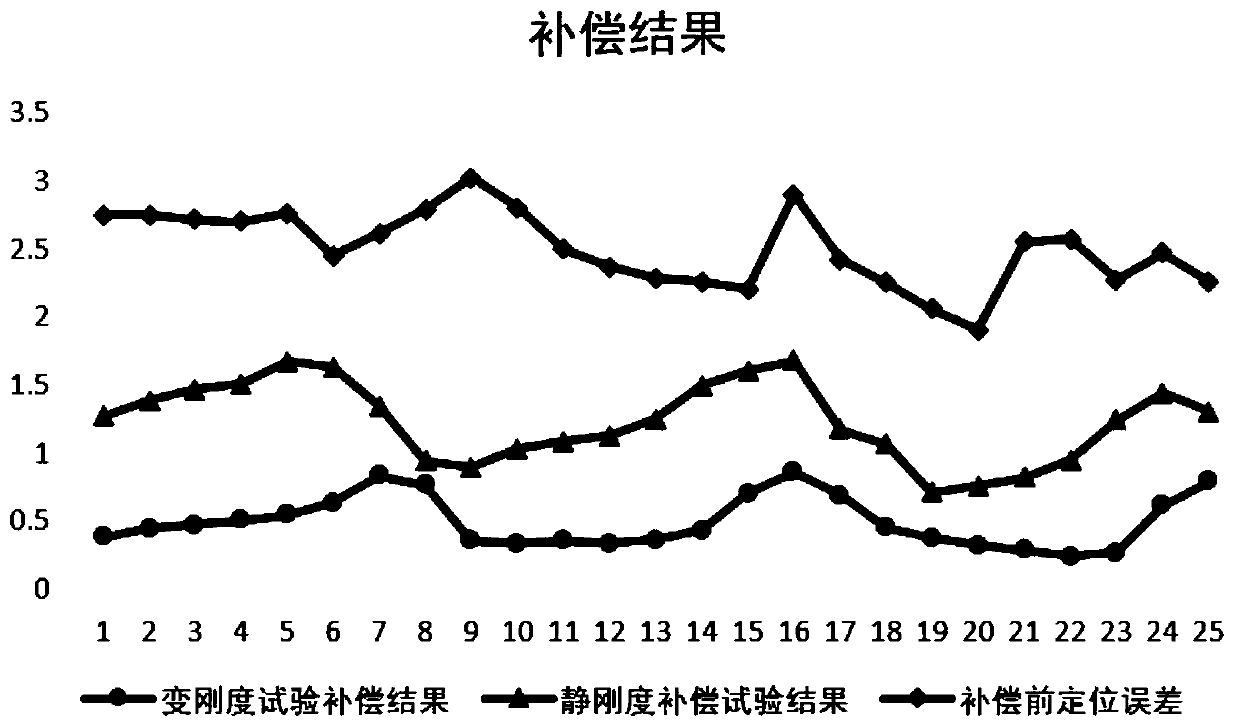

[0035] refer to figure 1 As shown, an industrial robot variable parameter stiffness identification and modeling method of the present invention includes the following steps:

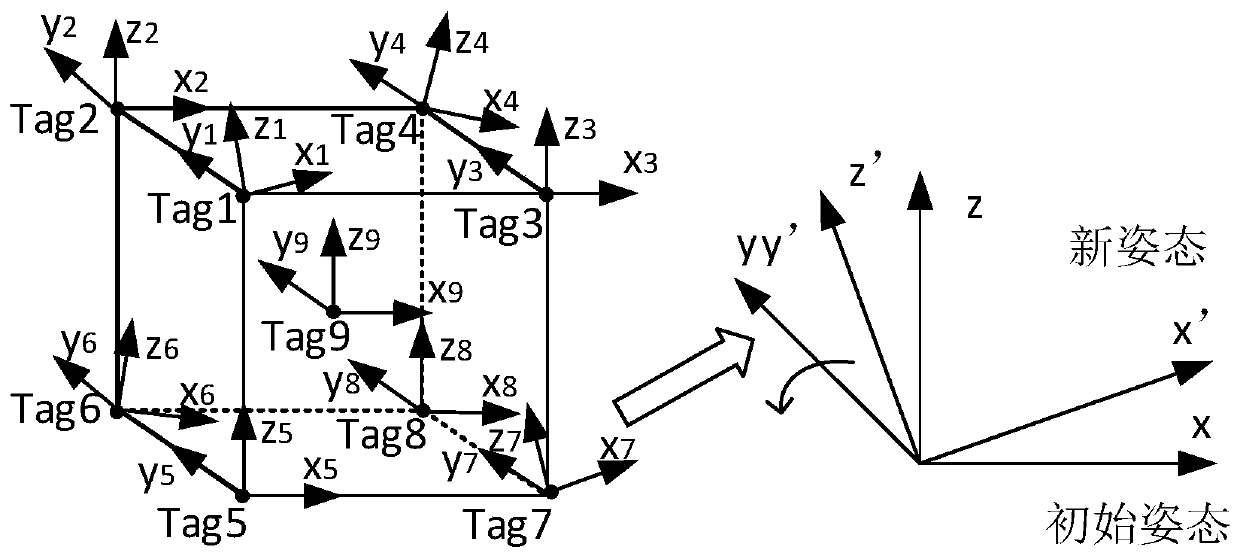

[0036] Step 1: Put the laser tracker in a suitable position for easy measurement. Use the laser tracker to measure and establish the coordinate system including the robot base coordinate system Base, the flange coordinate system Flange, the tool coordinate system Tool, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com