Curve transition method of variable thickness strip transition area

A transition curve and transition zone technology, applied in the field of variable thickness strip rolling, can solve problems such as the inability to meet the adjustability requirements, and achieve the effect of reducing the maximum rolling force and eliminating the sudden change of rolling force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

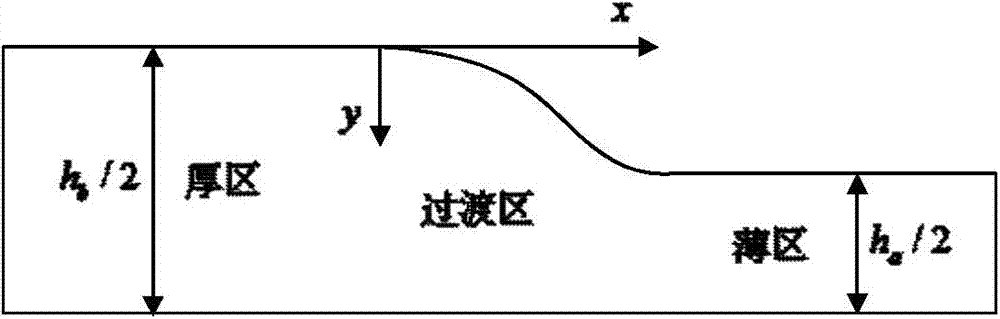

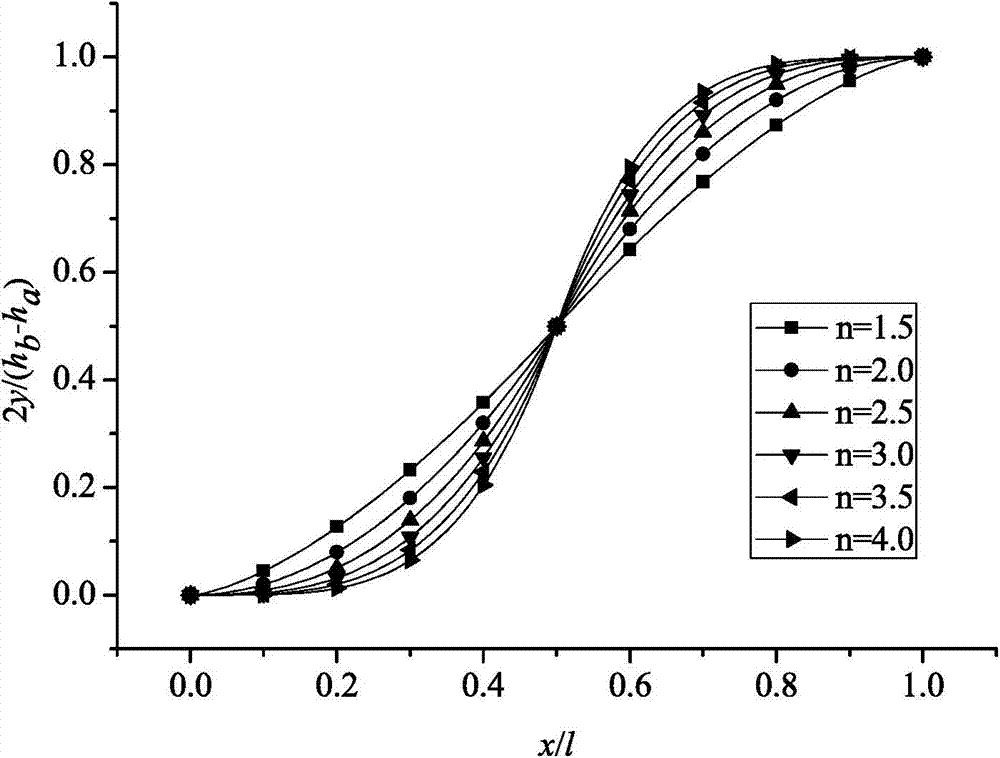

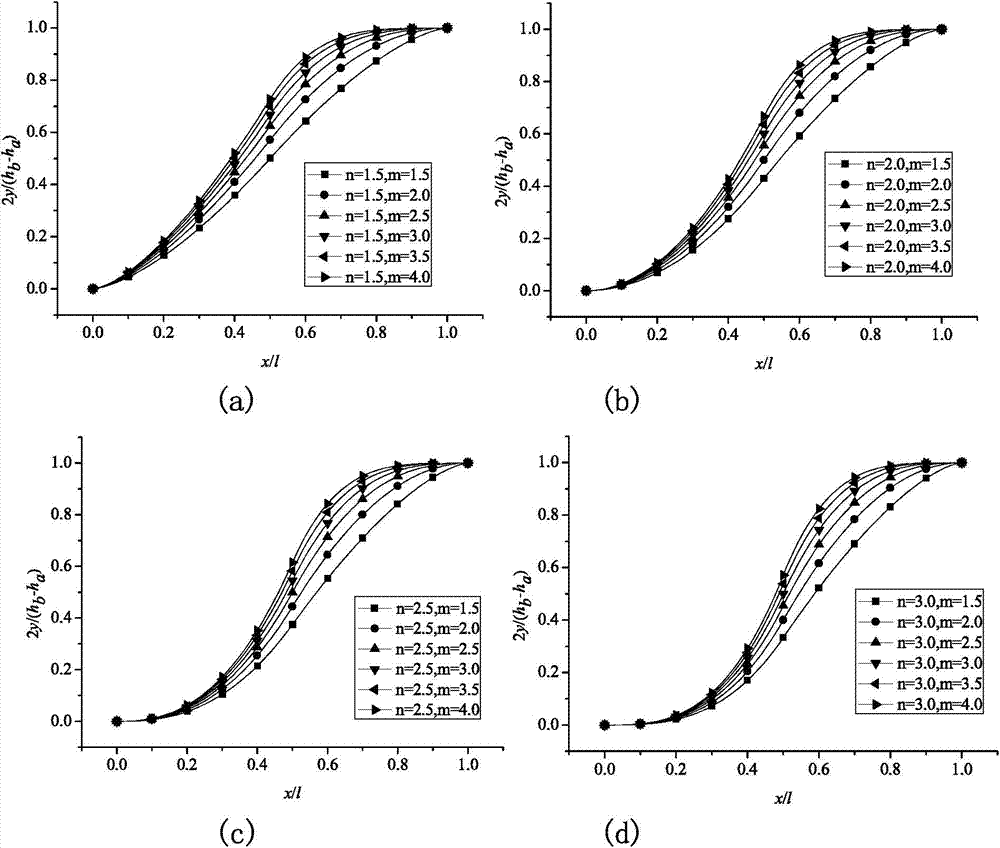

[0037] It is known that the rolling material is AISI-1045, the length of the transition zone is l=60mm, the thickness of the incoming material is 3.0mm, and the thickness of the thick zone is h b =2.7mm, the thickness of the thin area is h a = 2.1 mm. If the double power function curve with the same power index in the first half and the second half is adopted, the curve equation is:

[0038] y = 0.15 30 n x n 0 ≤ x ≤ 30 , n > 1 y = 0.3 - 0.15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com