Work machine maintenance system

A technology for working machines and maintenance systems, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., and can solve problems such as high time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described below with reference to the drawings.

[0018] The configuration, shape, size, and arrangement relationship described in the embodiments are merely schematic descriptions to the extent that the present invention can be understood and implemented. Therefore, the present invention is not limited to the embodiments described below, and various changes can be made without departing from the scope of technical ideas shown in the claims.

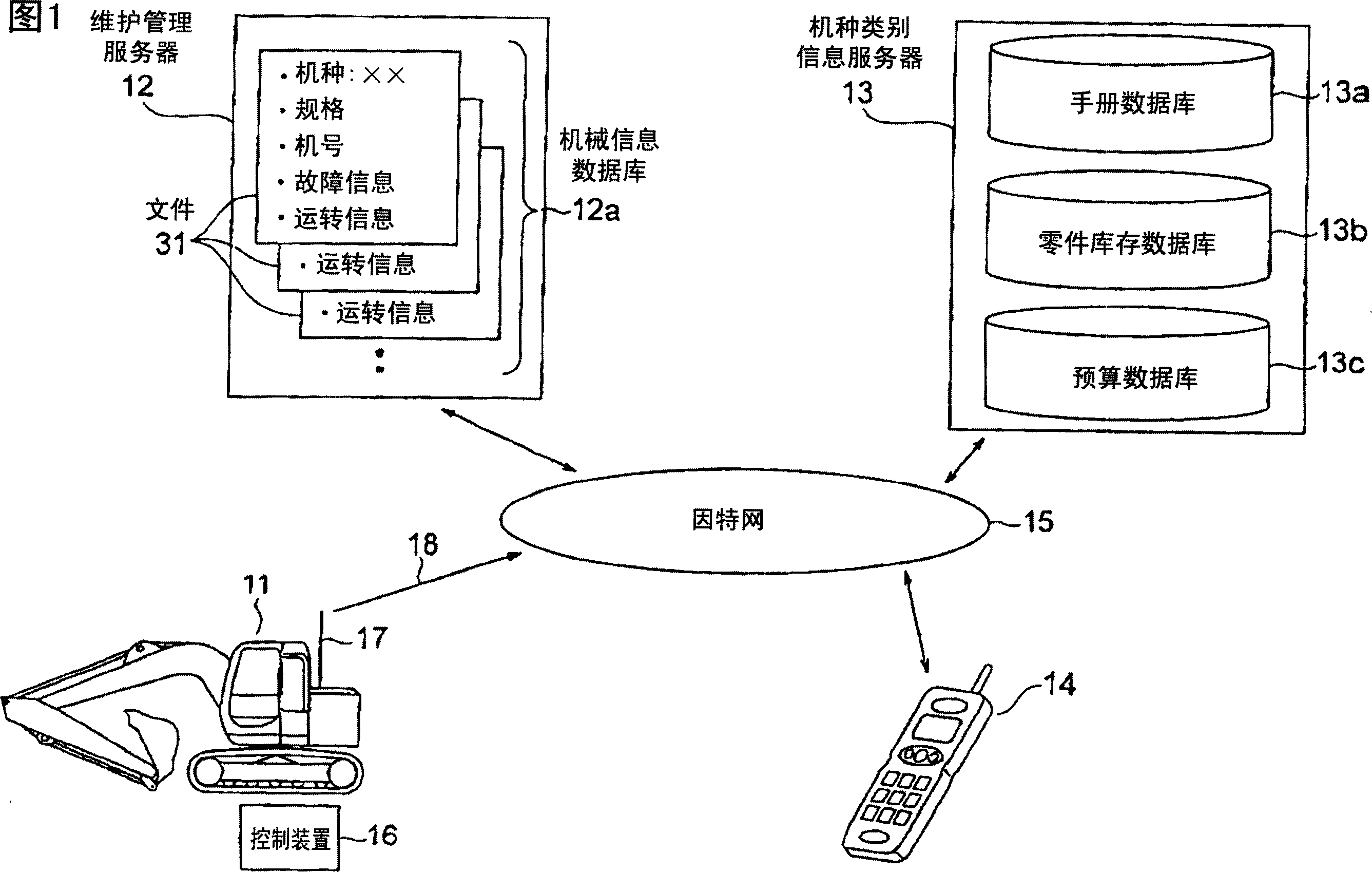

[0019] FIG. 1 shows the overall configuration of the maintenance system according to the present invention. In this embodiment, a hydraulic excavator will be described as a working machine. In FIG. 1 , a hydraulic excavator 11 , a maintenance management server 12 , a model category information server 13 , and a mobile phone 14 are shown installed at a work site. These are connected by a network (electrical communication line) 15, and data and the like can be transmitted / rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com