System for marking components and for verifying the applied marking

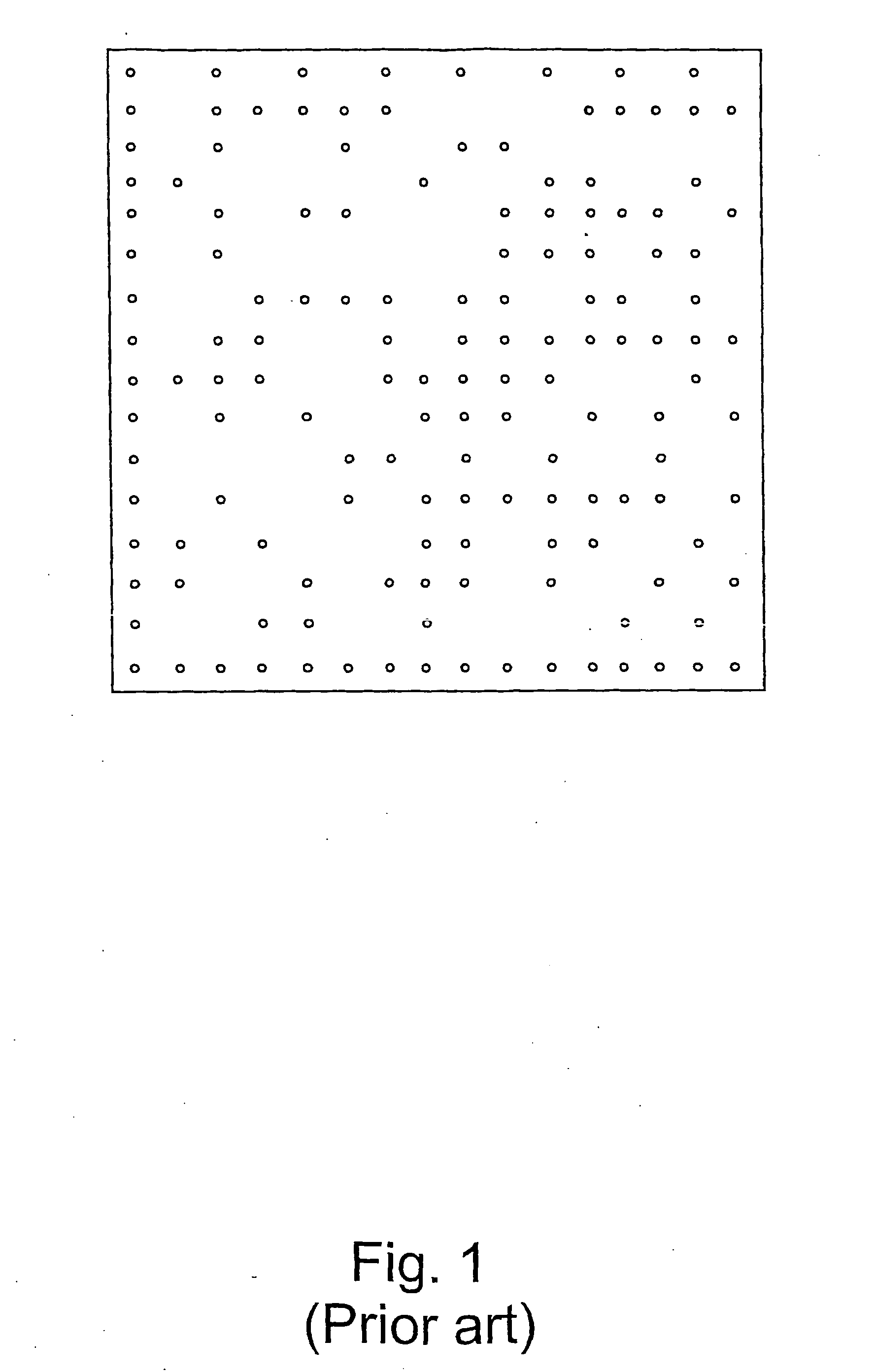

a technology for components and verification systems, applied in the field of marking, can solve the problems of scrapping whole components, difficult to comply with data matrix marking specifications, and severe operation conditions of engine aircraft components in particular, and achieve the effect of easy determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] There will now be described by way of example the best mode contemplated by the inventors for carrying out the invention. In the following description numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent however, to one skilled in the art, that the present invention may be practiced without limitation to these specific details. In other instances, well known methods and structures have not been described in detail so as not to unnecessarily obscure the present invention.

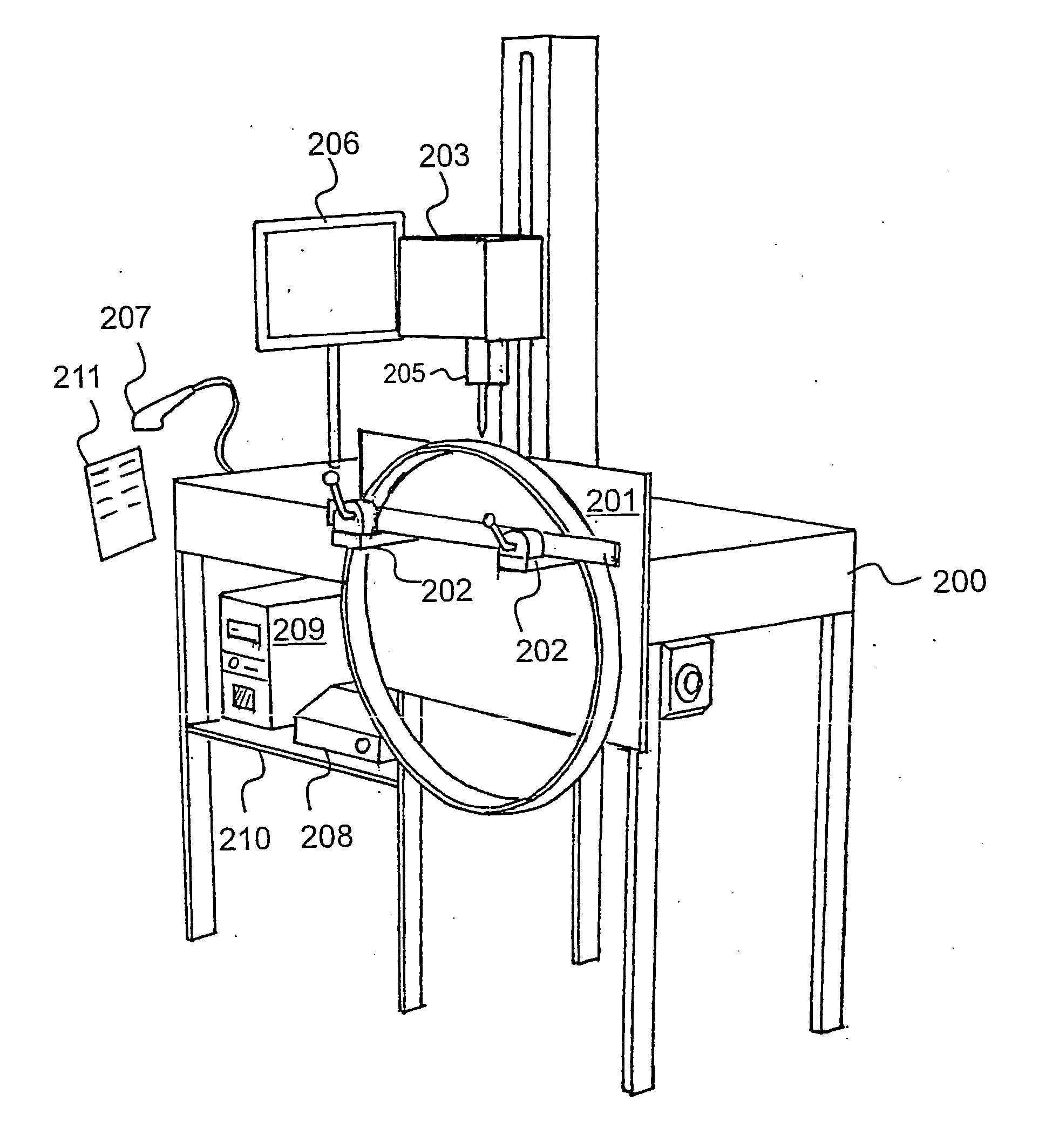

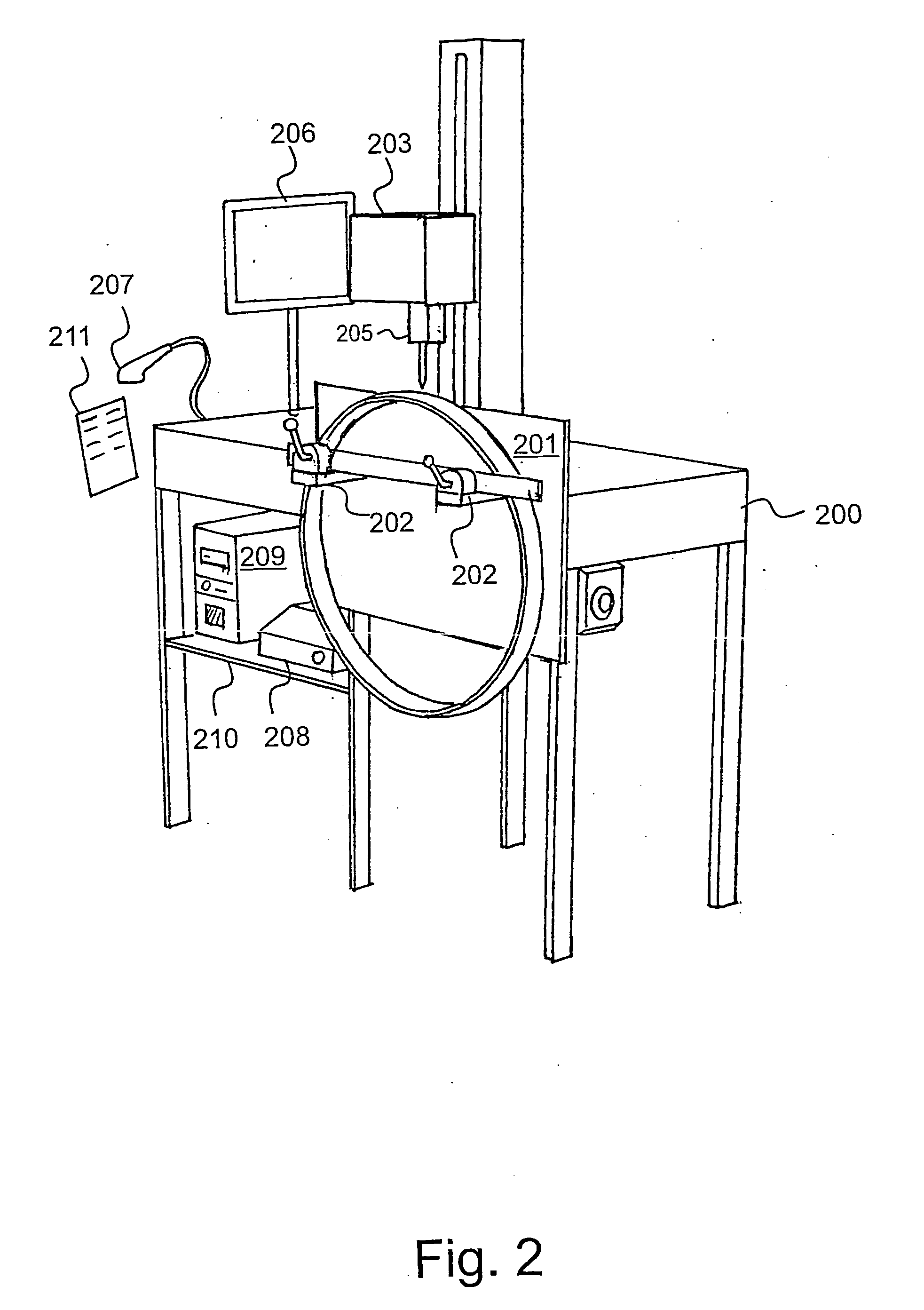

[0093] Specific implementations according to the present invention provide for an integrated marking and verification system for applying marks to components, in particular Data Matrix marks, and performing viewing and verification of those marks immediately after application of the marks, in an automated and integrated marking and verification operation.

[0094] A component to be marked is held firmly in a mounting device, and a mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com