Voltage-regulating energy saving spark machining pulse power supply

A technology of pulse power supply and electric spark, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of reducing the utilization rate of electric energy and limiting the adjustment range of pulse parameters, so as to save costs, reduce volume and weight, and achieve high The effect of high-frequency electromagnetic radiation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

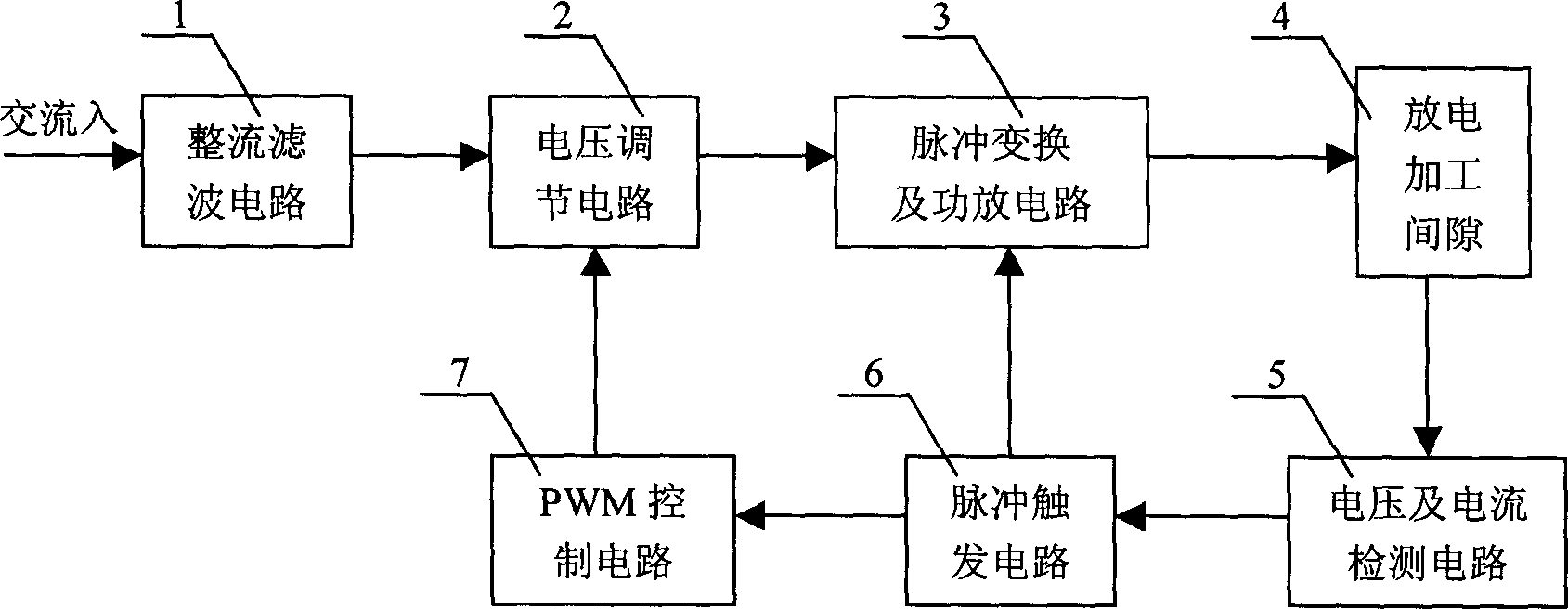

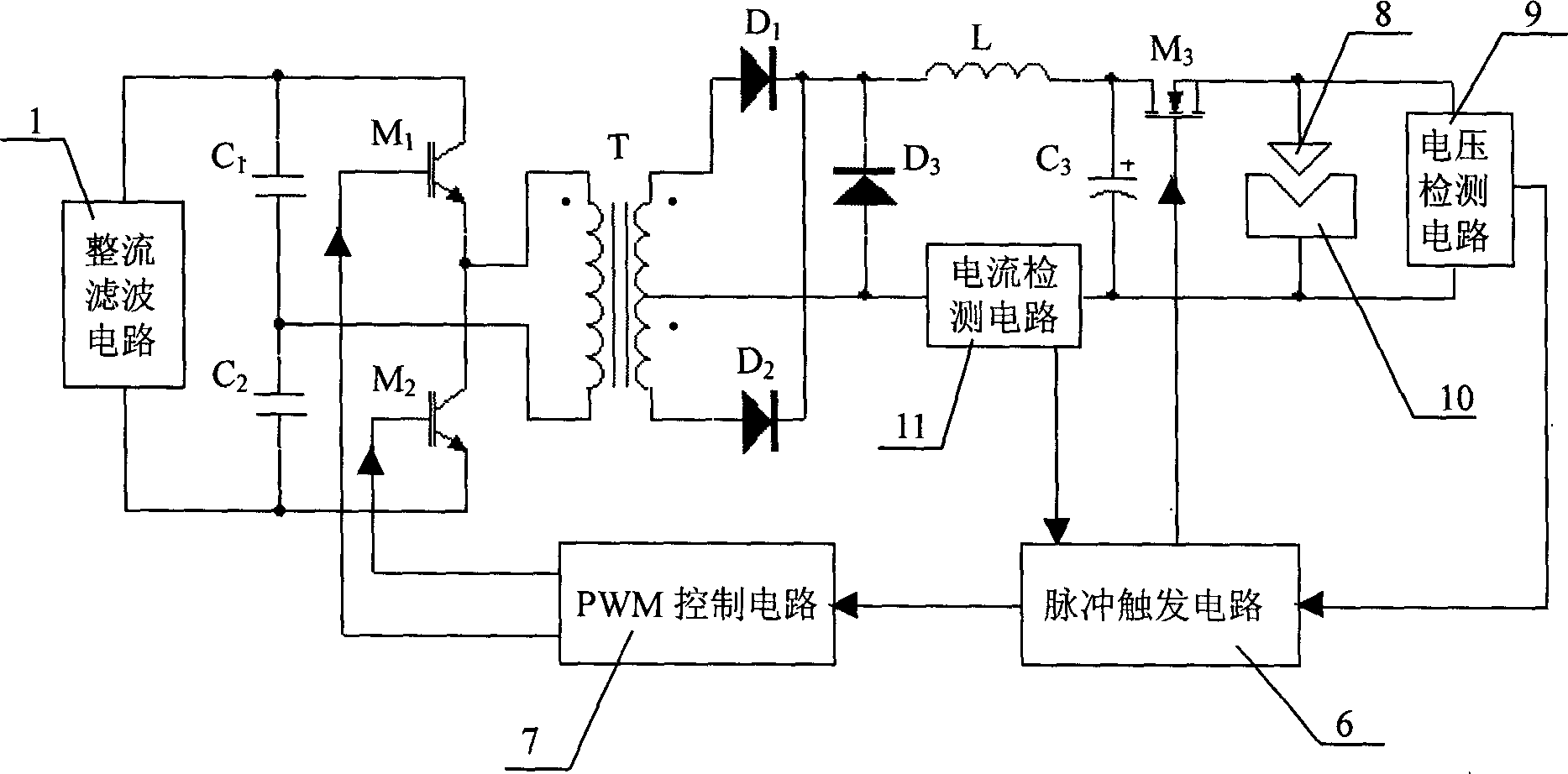

[0016] See figure 1 . The voltage-regulating energy-saving EDM pulse power supply of the present invention includes a rectifier filter circuit 1, a voltage adjustment circuit 2, a pulse conversion and power amplifier circuit 3, a voltage and current detection circuit 5, a pulse trigger circuit 6, and a PWM control circuit 7. The rectifier filter circuit 1 converts the alternating current into a regulated direct current, and delivers the direct current to the voltage regulation circuit 2. The voltage regulation circuit 2 automatically adjusts the voltage according to the control command sent by the PWM control circuit 7, and sends it to the pulse conversion and power amplifier circuit 3. When the high voltage of about 100V is output, it is used to break the discharge gap. When the gap is broken down, its output is adjusted to a machining maintenance voltage of about 25V. When the pulse discharge enters the discharge interval for deionization, the circuit outputs no load again Volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com