White car body assembly product line ski reciprocation conveying system branch station lifting mechanism

A technology of conveying system and lifting mechanism, which is applied to conveyer objects, motor vehicles, transportation and packaging, etc., can solve problems such as large kinetic energy loss, heavy mechanical maintenance workload, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

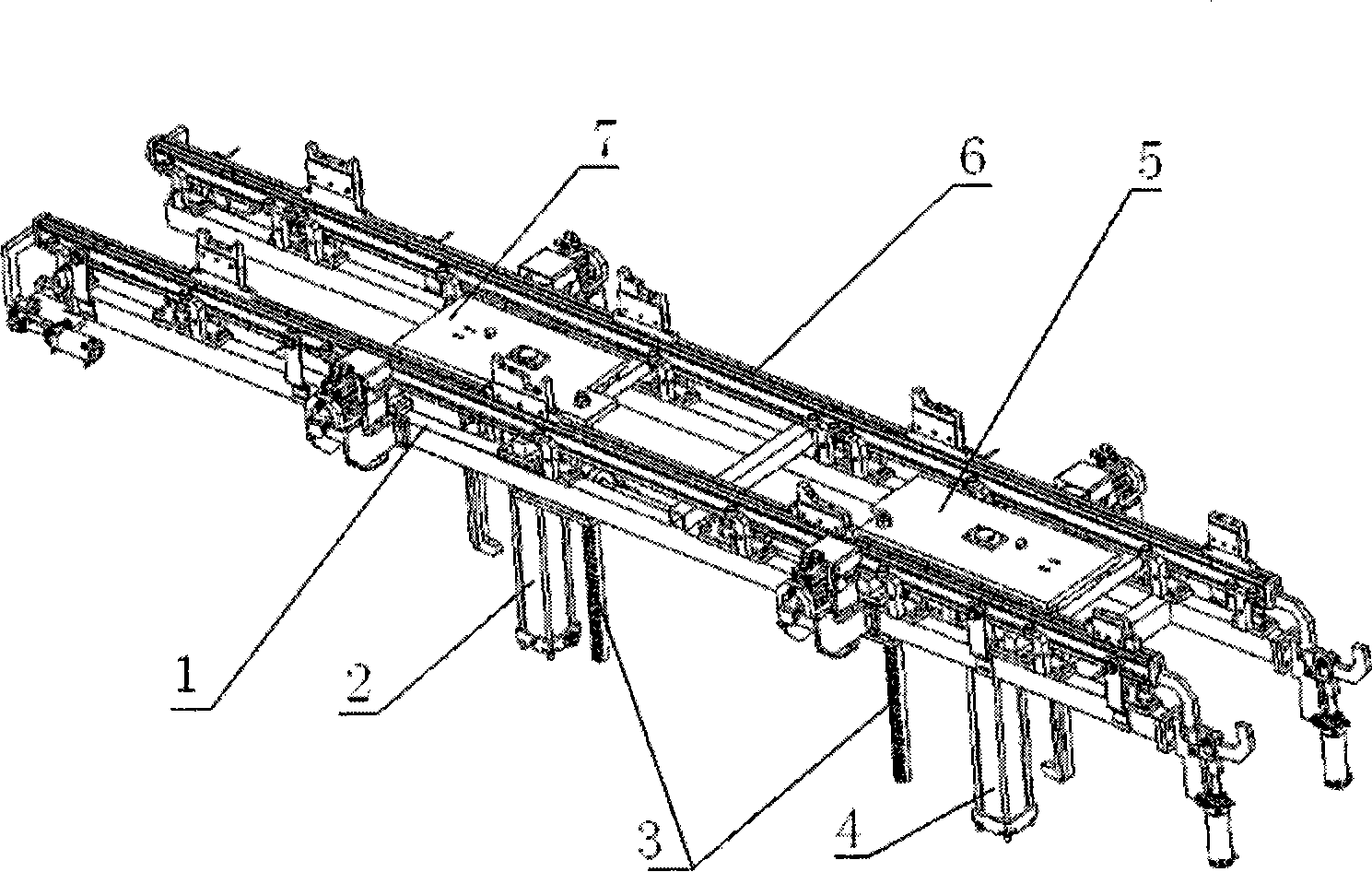

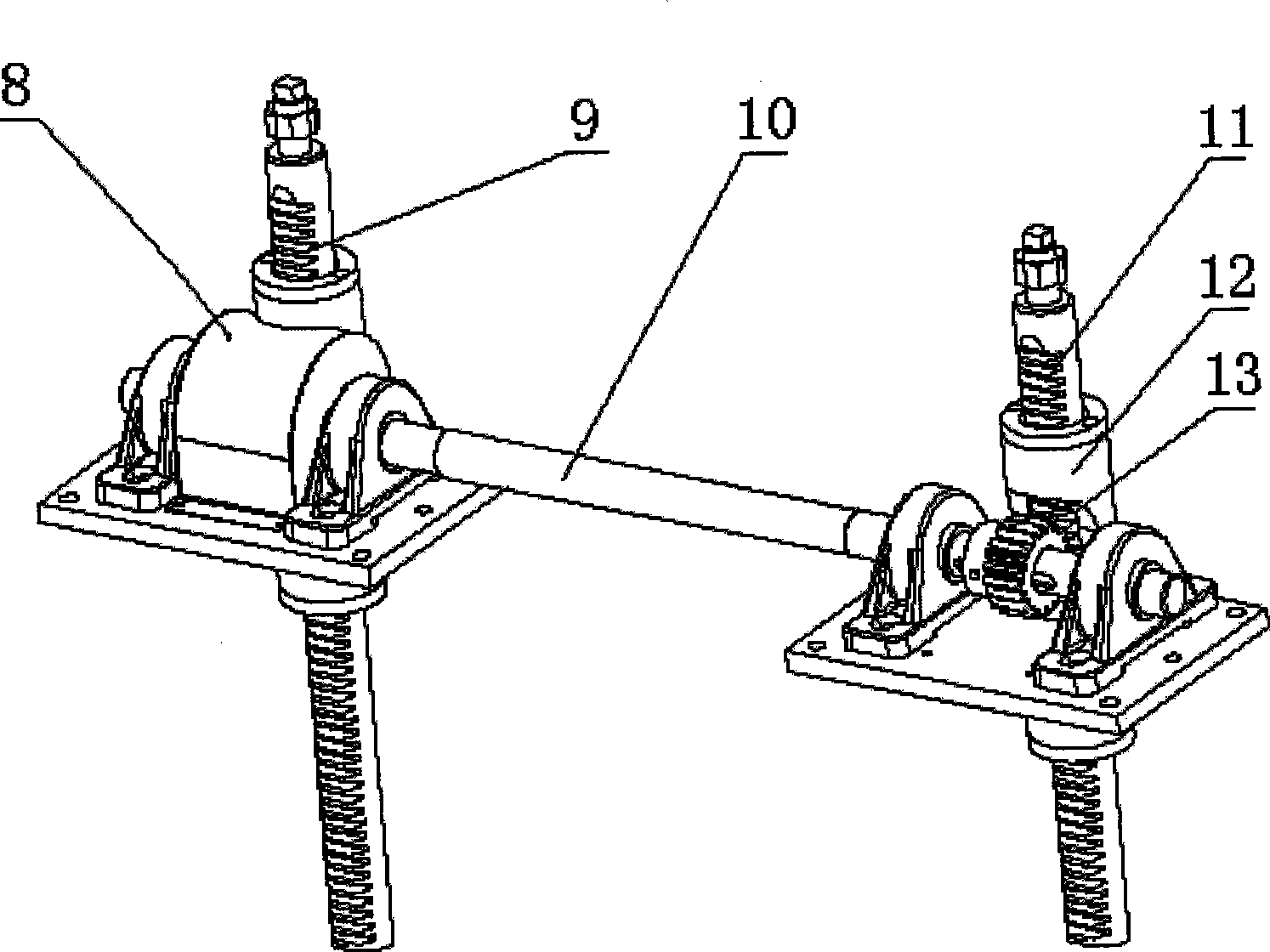

[0011] A car body-in-white assembly production line skid back-and-forth conveying system sub-station lifting mechanism, which has multiple sub-station lifting mechanisms with the same structure, such as figure 1 , figure 2 As shown, each substation lifting mechanism includes a first mounting plate 7, a second mounting plate 5, a first cylinder 2, a second cylinder 4 and a synchronizer 3, and the first mounting plate 7 and the second mounting plate 5 are located at the substation Between the slides 6 above the base 1 , the first cylinder 2 is vertically connected below the first mounting plate 7 , and the second cylinder 4 is vertically connected below the second mounting plate 5 . The synchronizer includes a first rack guide rod 9, a connecting rod 10, a second rack guide rod 11, pinion gears 13 at both ends of the connecting rod 10 and connecting rod seats 8, 12, the first rack guide rod 9 and the second rack guide rod The bar guide rods 11 mesh with the pinion gears 13 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com