Corrosion-resistant high-strength conductive concrete and preparation method thereof

A conductive concrete, high-strength technology, used in manufacturing tools, ceramic molding machines, etc., can solve the problems of unsuitable conductive concrete conductive medium, loss of conductivity, poor corrosion resistance, etc., to achieve good conductivity, strong conductivity, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh the raw materials according to the following parts by weight: 50 parts of cement, 50 parts of river sand, 5 parts of graphite, 1 part of stainless steel fiber (4-8 microns in diameter, 3-6 mm in length), 40 parts of water, 5 parts of silica powder, Dispersant 0.1 part. Then follow the steps below to prepare conductive concrete:

[0047] 1) Dissolve the dispersant in water first, then put the stainless steel fiber in the water and stir thoroughly;

[0048] 2) Add cement, graphite and silicon micropowder to the mixed liquid obtained in step 1), and stir with the mixer quickly (285±10 rpm) for 5-6 minutes, and stir evenly;

[0049] 3) Add river sand to the mixture obtained in step 2), and stir with the mixer quickly (285±10 rpm) for 10-15 minutes, and stir evenly;

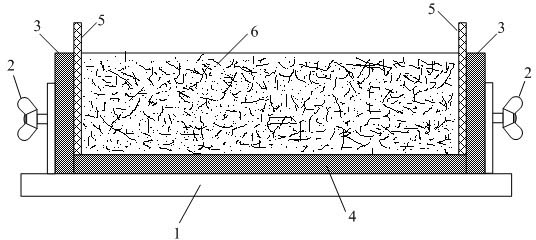

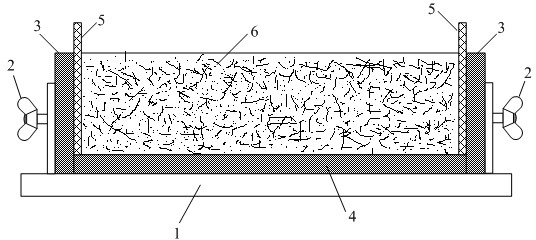

[0050] 4) Pour the cement mortar obtained in step 3) into such figure 1 molded in the mold shown;

[0051] 5) Release the mold after 24 hours of curing in the standard curing room, and cure to the spe...

Embodiment 2

[0054] Weigh raw materials according to the following parts by weight: 80 parts of cement, 80 parts of river sand, 15 parts of graphite, 5 parts of carbon fiber (4-8 microns in diameter, 3-6 mm in length), 70 parts of water, 8 parts of micro-silica powder, dispersed 0.5 parts of the agent. Then follow the steps below to prepare conductive concrete:

[0055] 1) Dissolve the dispersant in water first, then put the stainless steel fiber in the water and stir thoroughly;

[0056] 2) Add cement, graphite and silicon micropowder to the mixed liquid obtained in step 1), and stir it with a mixer at a rapid speed (285±10 rpm) for 5-6 minutes, and stir evenly;

[0057] 3) Add river sand to the mixture obtained in step 2), and stir with the mixer quickly (285±10 rpm) for 10-15 minutes, and stir evenly;

[0058] 4) Pour the cement mortar obtained in step 3) into such figure 1 molded in the mold shown;

[0059] 5) Release the mold after 24 hours of curing in the standard curing room, a...

Embodiment 3

[0062] Weigh the raw materials according to the following parts by weight: 100 parts of cement, 100 parts of river sand, 40 parts of graphite, 15 parts of stainless steel fiber (4-8 microns in diameter, 3-6 mm in length), 110 parts of water, 8 parts of silica powder, Dispersant 0.8 parts. Then follow the steps below to prepare conductive concrete:

[0063] 1) Dissolve the dispersant in water first, then put the stainless steel fiber in the water and stir thoroughly;

[0064] 2) Add cement, graphite and silicon micropowder to the mixed liquid obtained in step 1), and stir it with a mixer at a rapid speed (285±10 rpm) for 5-6 minutes, and stir evenly;

[0065]3) Add river sand to the mixture obtained in step 2), and stir with the mixer quickly (285±10 rpm) for 10-15 minutes, and stir evenly;

[0066] 4) Pour the cement mortar obtained in step 3) into such figure 1 molded in the mold shown;

[0067] 5) Release the mold after 24 hours of curing in the standard curing room, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com