Method for preparing particle-filled conductive thermoplastic polymer

A high polymer and thermoplastic technology, applied in the field of electromagnetic shielding material preparation, can solve the problems of reducing the strength of composite materials, electromagnetic shielding conduction, prone to residual impurities, and increasing process complexity, etc., achieving low cost, high yield, The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with an embodiment, but the application of the present invention is not limited to the following specific examples of implementation.

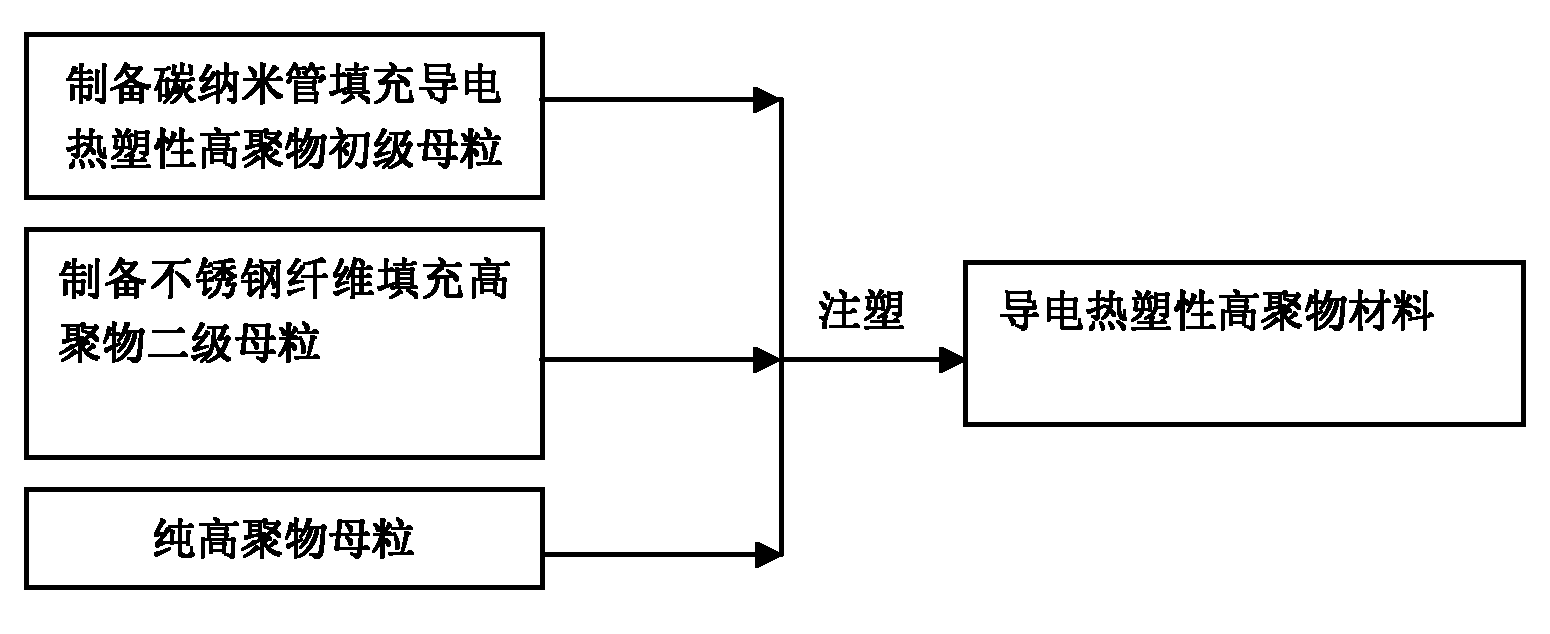

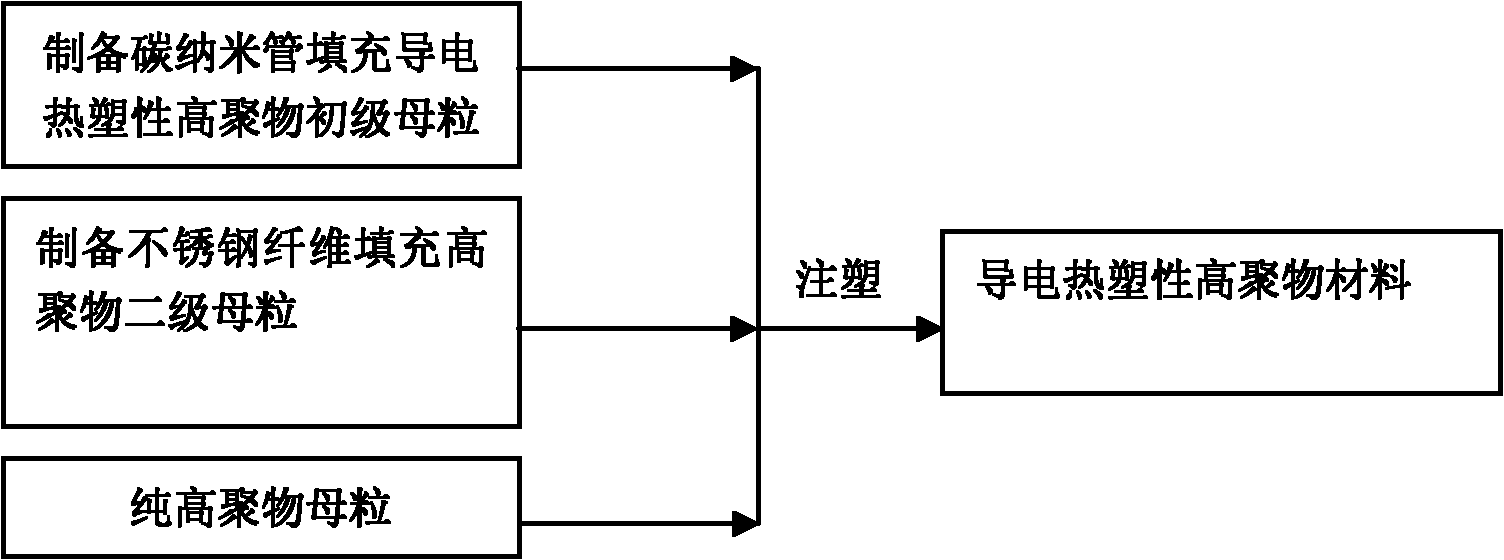

[0018] With reference to Fig. 1, the preparation process of the present invention is as follows:

[0019] 1. The pure polymer masterbatch is baked in an oven at 60-120°C for more than 8 hours.

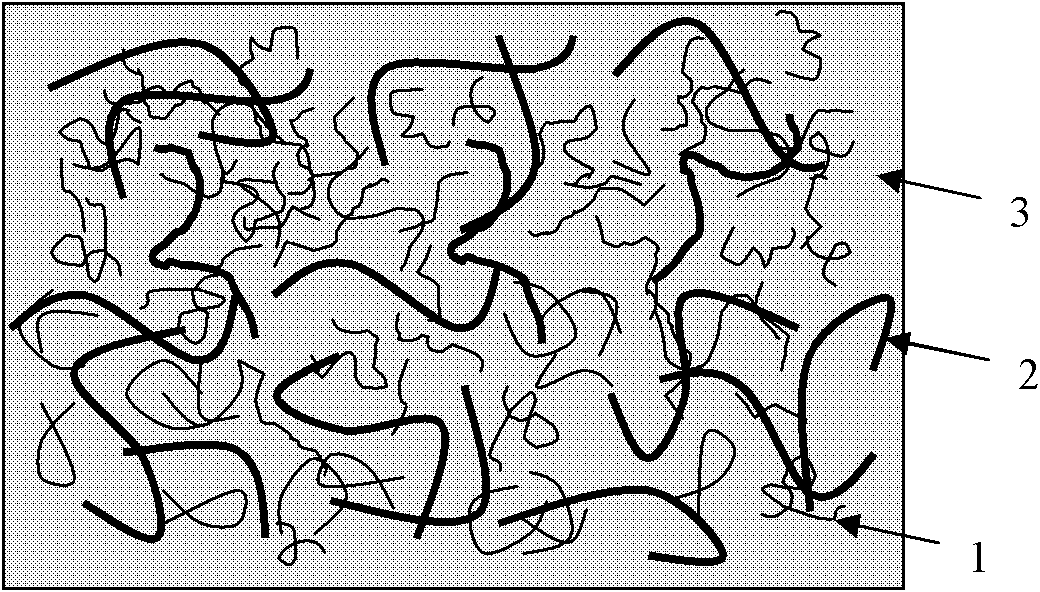

[0020] 2. Mix carbon nanotubes and pure high polymer masterbatch in a mixer (including drum type, vertical mixer or electric mixer), wherein the mass fraction of carbon nanotubes is 0.1%-20%, pure high polymer Including: PP (polypropylene), PE (polyethylene), PS (polystyrene), PC (polycarbonate), ABS (acrylonitrile-styrene-butadiene copolymer), PA (polyamide, commonly known as nylon ), PBT (polybutylene terephthalate, commonly known as polyester), PET (polyethylene terephthalate), PPO (polyphenylene ether), PPS (polyphenylene sulfide), PVC (rigid polyethylene Vinyl chloride),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com