Method for producing cold-rolled stainless steel annealing and pickling brand steel

A production method, stainless steel technology, applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of large gas consumption, affecting the quality of strip steel, and large environmental pollution, so as to reduce pollution and acid consumption, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

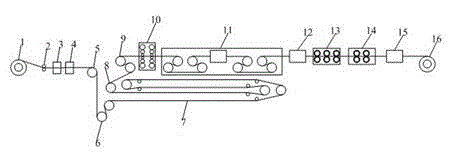

[0027] The production method of stainless steel annealing and pickling steel strip for cold rolling provided by the invention comprises the following steps:

[0028] (1) After the strip is uncoiled and welded, it is rolled directly through two online six-roll mills without lubrication, and the reduction rate is 30~60%;

[0029] (2) After the strip steel is rolled by an online six-high rolling mill, the strip steel is stretched and straightened and phosphorus is broken, and the elongation rate is 2% to 7%;

[0030] (3) After the strip steel is stretched and straightened to break phosphorus, the strip steel is subjected to shot blasting treatment. The shot blasting treatment is a slurry sprayed with a mixture of water and abrasives, wherein the volume percentage of the abrasives in the slurry is 30~ 40%;

[0031] (4) After the shot blasting treatment, use the scrubbing machine to grind and scrub the strip steel, and grind and scrub rollers at least 4 pairs to remove the oxide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com