Fluid composition concentration test method and device thereof

A concentration measurement and fluid technology, which is applied in the field of fluid composition concentration measurement and devices, and can solve the problems of high atmospheric composition and inapplicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

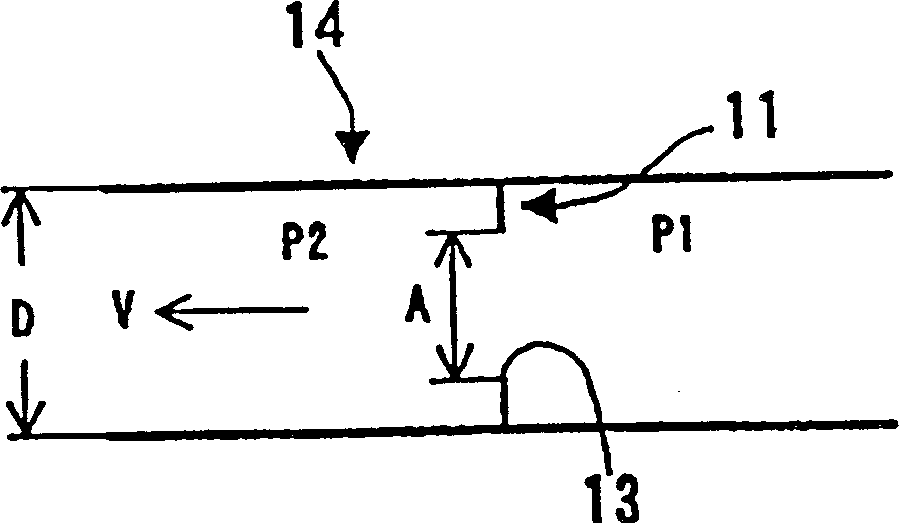

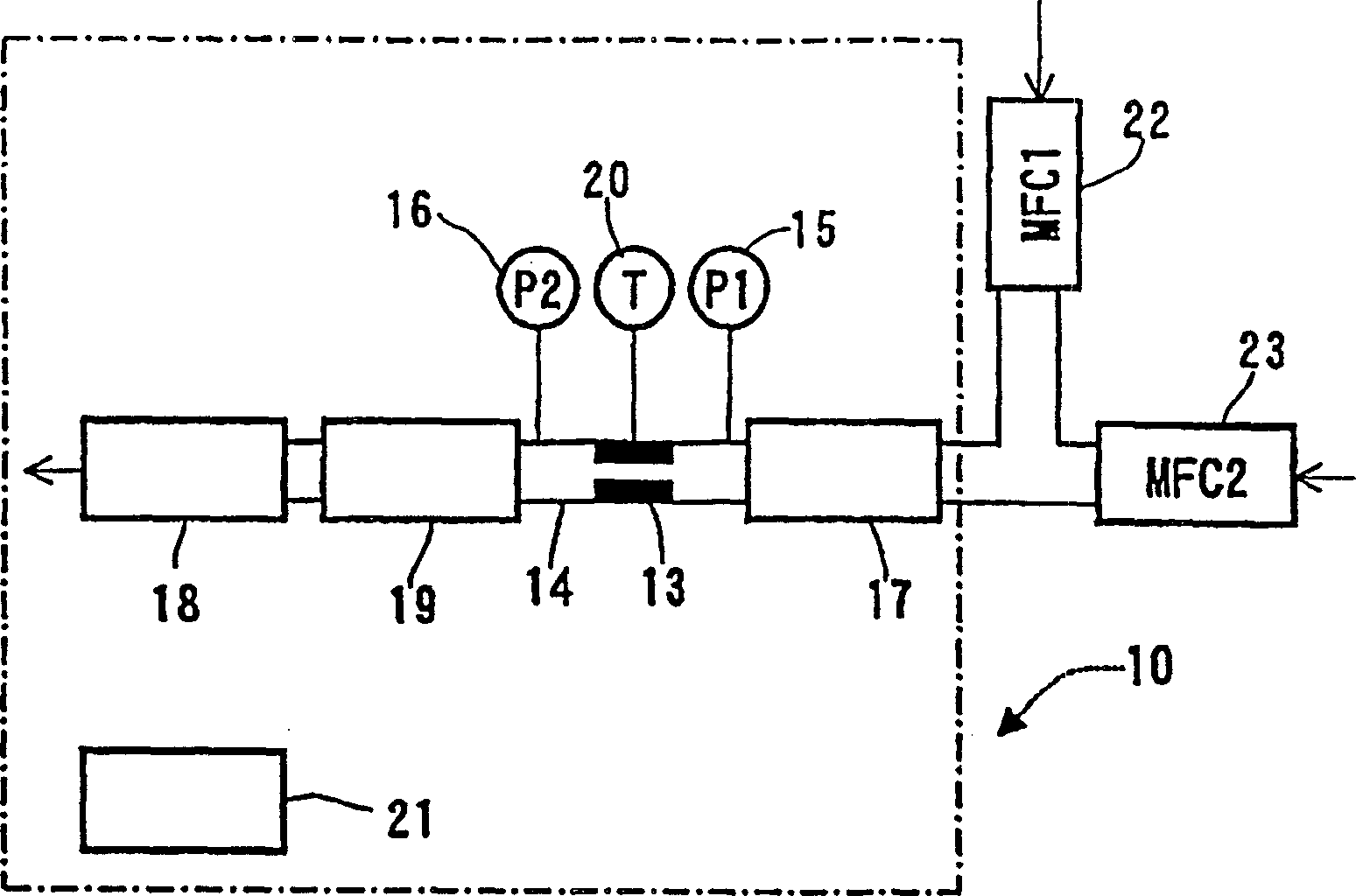

[0065] use as Figure 9 The experimental setup shown. In this experimental device, a pipe provided with a needle valve (UVCIILM manufactured by Motoyama Seisakusho) 13b was used as the pipe for measurement. The first flow controller 22 for introducing krypton (Kr) and nitrogen (N 2 ) The second flow controller and back pressure regulating valve (UR7340B manufactured by STEC) 17a for introduction, and the flow controller (mass flow controller: SEF4400 manufactured by STEC, heat conduction type mass flow meter) 19 is installed downstream.

[0066] The opening degree of the needle valve 13b is set to be appropriate, the back pressure regulating valve 17a is set to a state of 145Kpa, and the two flow controllers 22 and 23 are operated to change the mixing ratio of krypton and nitrogen, and the flow rate after each mixing ratio passes through the needle valve 13b Measured with flow controller 19. The mixing ratio of krypton and nitrogen (Kr / N 2 ) is related to the flow output of...

no. 2 example

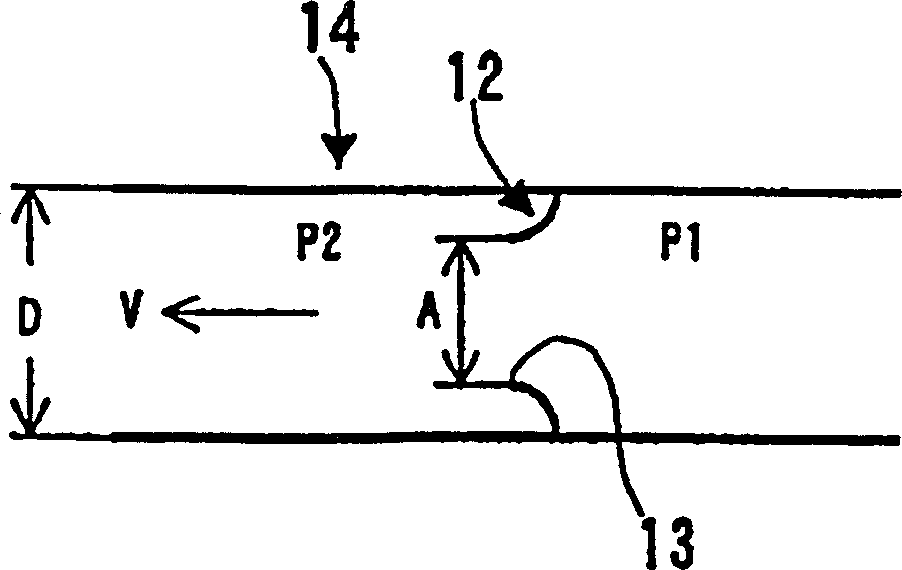

[0067] use as Figure 11 The experimental setup shown. This experimental device uses the experimental device of the first embodiment, plus an upstream side pressure measuring device 15 for measuring the pressure on the upstream side of the needle valve 13b, and a downstream side of the flow measuring device 19 for measuring the pressure on the downstream side of the needle valve 13b. A pressure measuring device 16 and a temperature measuring device as a temperature measuring means of the needle valve 13b.

[0068] The pressure difference between the front and rear of the needle valve 13b was set at a fixed value of 45Kpa, and 100% pure nitrogen was continuously supplied for about 16 hours. Meanwhile, the flow output of the flow measuring device 19 is expressed as Figure 12 . Moreover, the temperature change of the needle valve 13b measured by the temperature measuring device 20 at this time is as follows: Figure 13 . Furthermore, the relationship between measured temper...

no. 3 example

[0070] Using the same experimental device as the second embodiment, the temperature of the needle valve 13b is fixed at 25°C, 100% pure argon gas is introduced, and the pressure difference between the front and back of the needle valve 13b is changed to 100KPa, 200KPa, and 300KPa at intervals of 30 minutes , measure the flow output at this time. This result is as Figure 16 shown. Moreover, the relationship between differential pressure and flow output is as Figure 17shown. It can be seen from the results that there is a positive correlation between the pressure difference and the flow output, and the correlation coefficient in this case is 3.73. Then, this correlation coefficient is multiplied by the pressure difference from the reference pressure difference of 300KPa, and the pressure correction of the flow output is performed by multiplying it by the flow output at this time. The result is as Figure 18 shown.

[0071] From the above description, according to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com