Method for measuring slurry density of desulfurizing absorption column

A desulfurization absorption tower and absorption tower technology, which is applied in the direction of determining the specific gravity by measuring the pressure difference, can solve the problem that the specific implementation structure of the sampling and pressure measurement device is not mentioned, the implementation structure of the sampling and pressure measurement device is not mentioned, and there is no consideration problems such as the measurement system, to achieve the effect of convenient and reliable cleaning and maintenance, reduction of inherent errors, and easy measurement operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

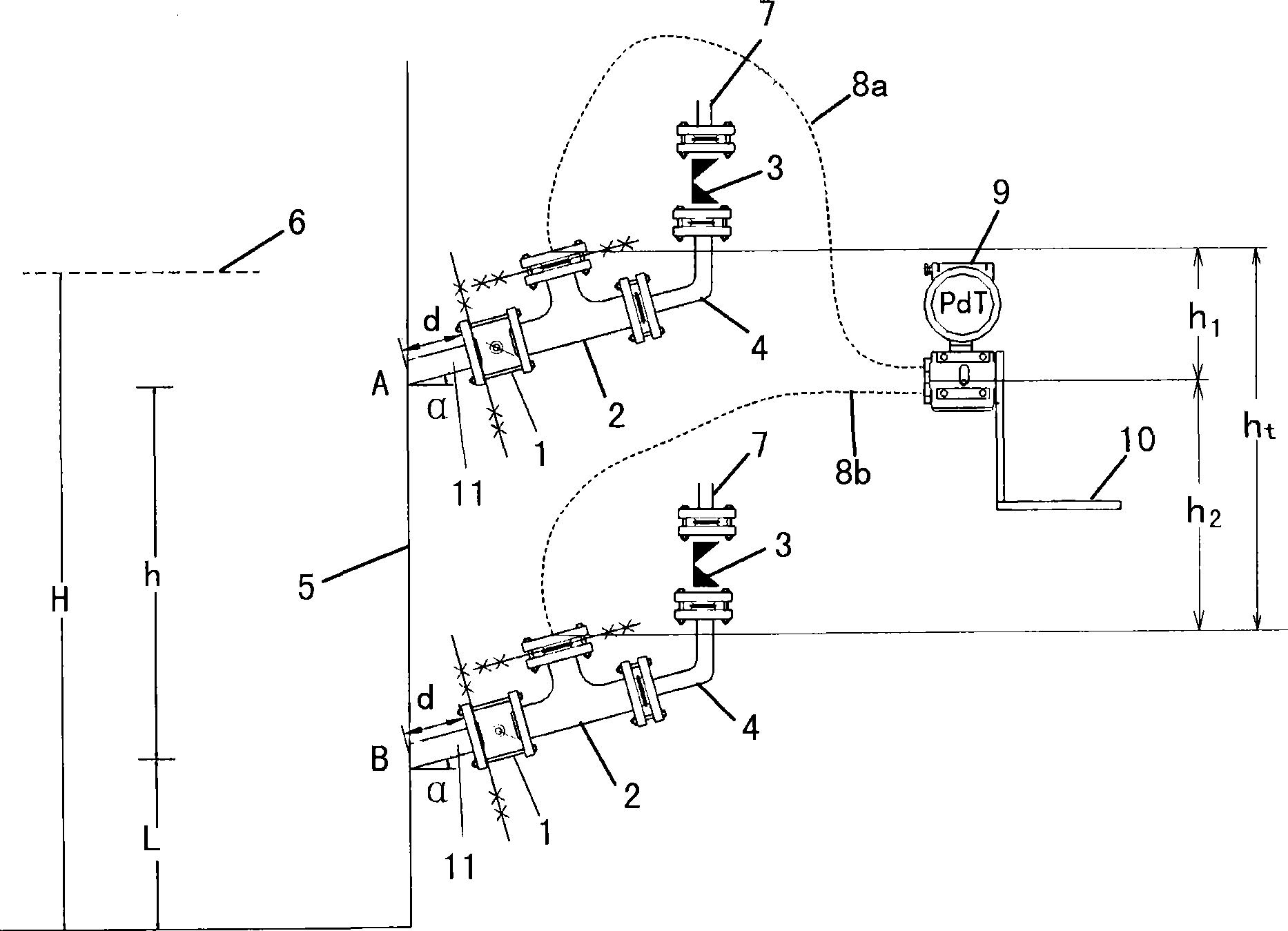

[0014] figure 1 One embodiment of implementing the method of the invention is shown. exist figure 1 Among them, the absorption tower 5 only schematically draws the bottom and side walls with lines, and usually this absorption tower 5 is erected in a cylindrical shape. Depend on figure 1 It can be seen that two pressure sampling points are selected on the absorption tower 5 in the height direction along the tower body, that is, the upper low-pressure side pressure sampling point A and the lower high-pressure side pressure sampling point B. Each pressure sampling point A or B is respectively led out through a sampling pipe section. In this embodiment, the above sampling pipe section is composed of an outlet pipe 11 , a valve 1 and a tee flange 2 . Here, the outlet pipe 11 is connected to one interface of the three-way flange 2 through the valve 1, the other interface of the three-way flange 12 is connected to the flushing water valve 3 through the flange adapter 4, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com