A Small Vertical Thrust Vectoring Test Bench

A technology of thrust vector and test bench, which is applied in the calibration/testing of force/torque/work measuring instruments, measuring force components, force/torque/work measuring instruments, etc., and can solve problems such as the influence of lateral force on horizontal structures , to achieve the effect of speeding up the calibration process, less complicated connections, and high force measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

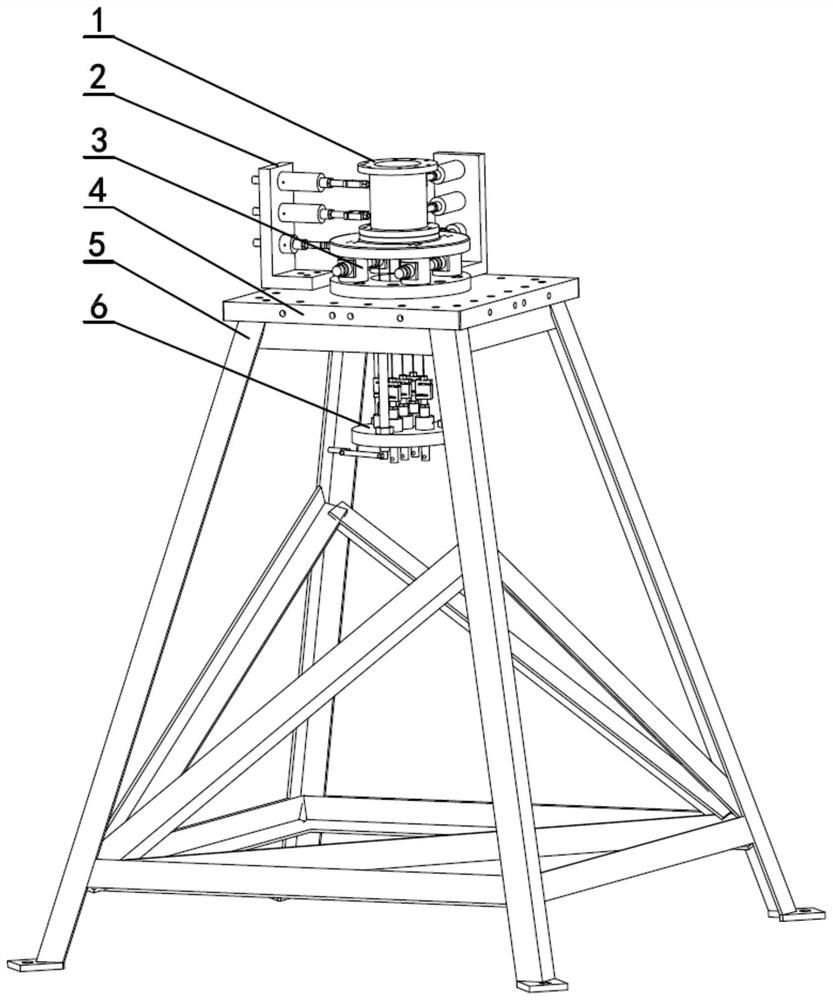

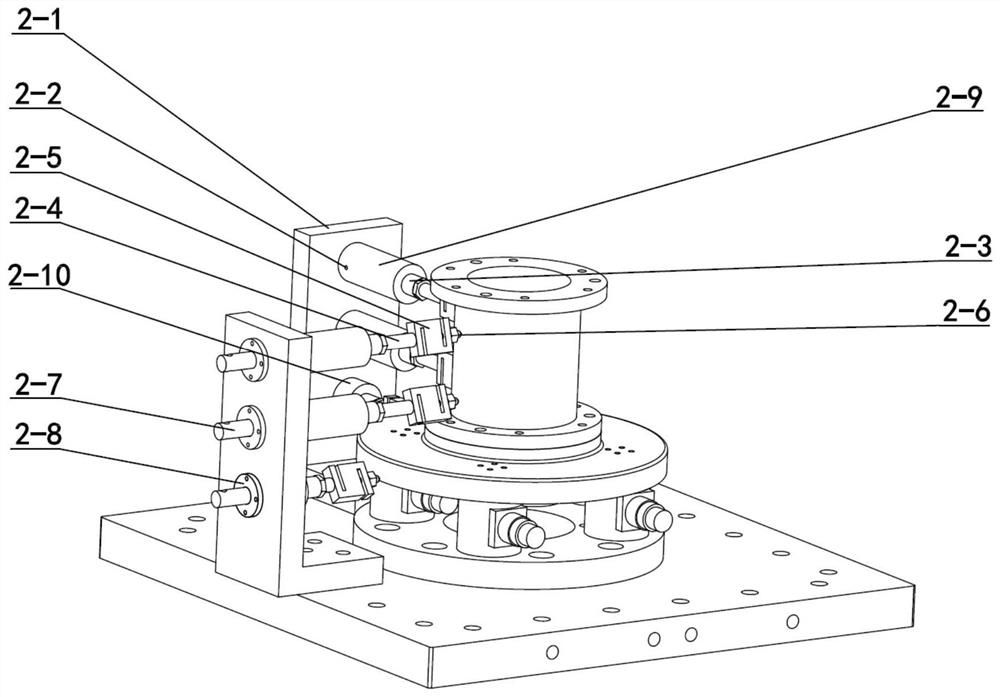

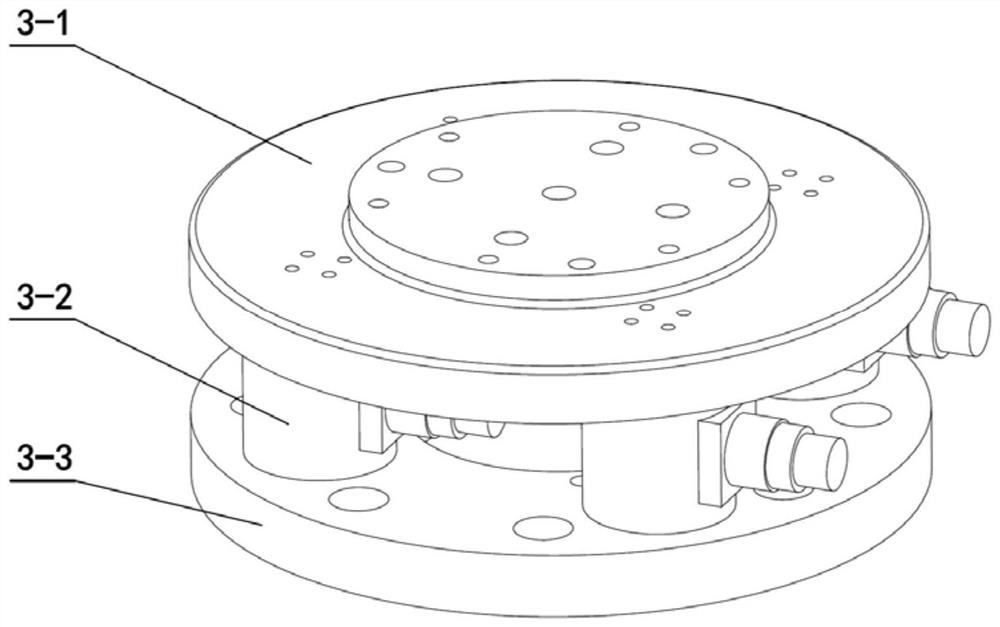

[0021] combine figure 1 , a small vertical thrust vectoring test bench according to the present invention, including a flange adapter 1 , a force measuring assembly 3 , a base plate 4 , a stand 5 , a main thrust calibration device 6 and two sets of side thrust calibration devices 2 . The stand 5 is fixed on the ground, the bottom plate 4 is fixed on the top surface of the stand 5, the center of the bottom plate 4 is provided with a through hole, the main thrust calibration device 6 is located below the bottom plate 4, and is fixedly connected with the bottom surface of the bottom plate 4, the force measuring assembly 3 Fixed on the top surface of the bottom plate 4, the main thrust calibration device 6 is connected to the force measuring component 3 through a through hole, the flange adapter 1 is fixed on the top surface of the force measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com