Icebound type pressure-maintaining and temperature-preserving sampler

A sampler and ice-sealed technology, which is applied in the field of pressure-holding and heat-preserving sampling drilling tools, can solve problems such as ball valves or plate valves are difficult to close normally, ball valves or plate valves are occupied, and core diameters are small, so as to improve the reliability of pressure-holding and Success rate, increasing core diameter and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment describe in further detail:

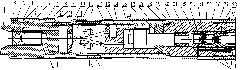

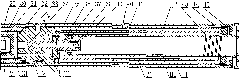

[0024] attached Figure 1a the right end of the attachment Figure 1b The left end constitutes a complete ice-sealed pressure-preserving and heat-preserving sampler.

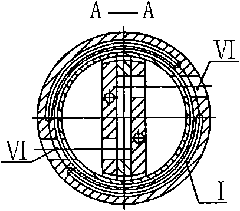

[0025] The ice-sealed pressure-preserving and heat-preserving sampler is composed of a drilling / sampling switching mechanism, a refrigerant circulation system, a mud ice valve and a core valve in-situ generating mechanism, a single-action mechanism for a core holding tube and channels I, II, III, IV, V, VI composition;

[0026] Drilling / sampling switching mechanism: the different-diameter joint 1 is connected to the diverter valve seat 2 through threads, the diverter valve seat 2 is connected to the return joint 8 through threads, the return joint 8 is connected to the outer pipe 17 through threads, and the diverter valve core 6 Insert diverter valve seat 2 and position it by retaining ring 3 and diverter valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com