Upright support configuration for a pallet racking system

a pallet racking and support configuration technology, applied in the direction of storage devices, cabinets, show hangers, etc., can solve the problems of lack of strength, high cost of heavy duty steel beams in pallet racking, and inconvenient use of heavy duty steel beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

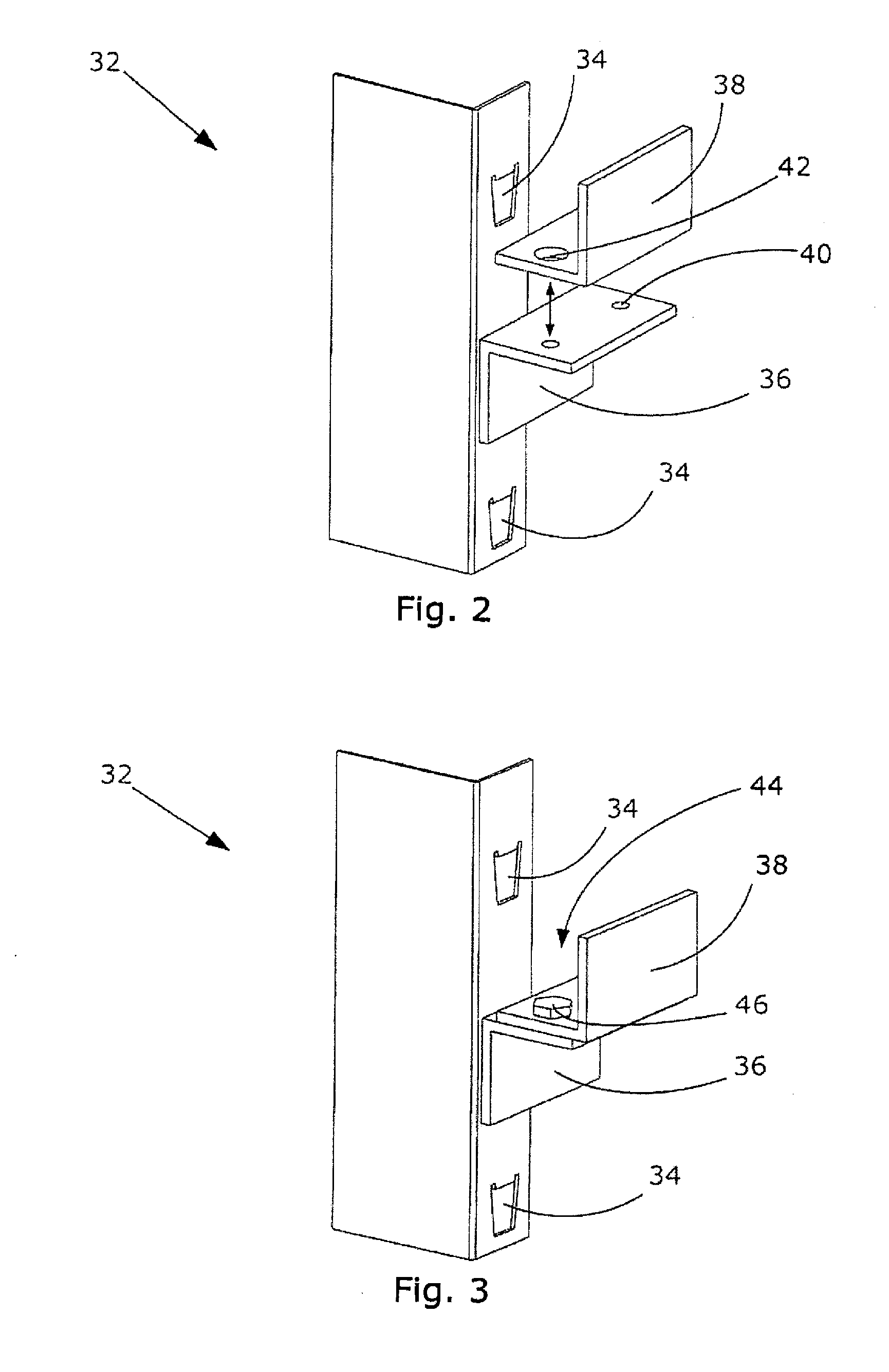

[0071]The following detailed description of the invention refers to the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings and the following description to refer to the same and like parts. Dimensions of certain parts shown in the drawings may have been modified and / or exaggerated for the purposes of clarity or illustration.

[0072]The present invention relates to a pallet racking system and bracket therefor which allows for horizontal cross beams supporting the pallets to be constructed of cheaper and lighter material and / or be of lesser cross sectional size than hitherto known beams used in conventional pallet racking systems. The present invention can be used in conjunction with either the “Pushback” or “Flowthrough” racking systems which are known, but it is to be understood that the invention could equally well be applied to any kind of racking system.

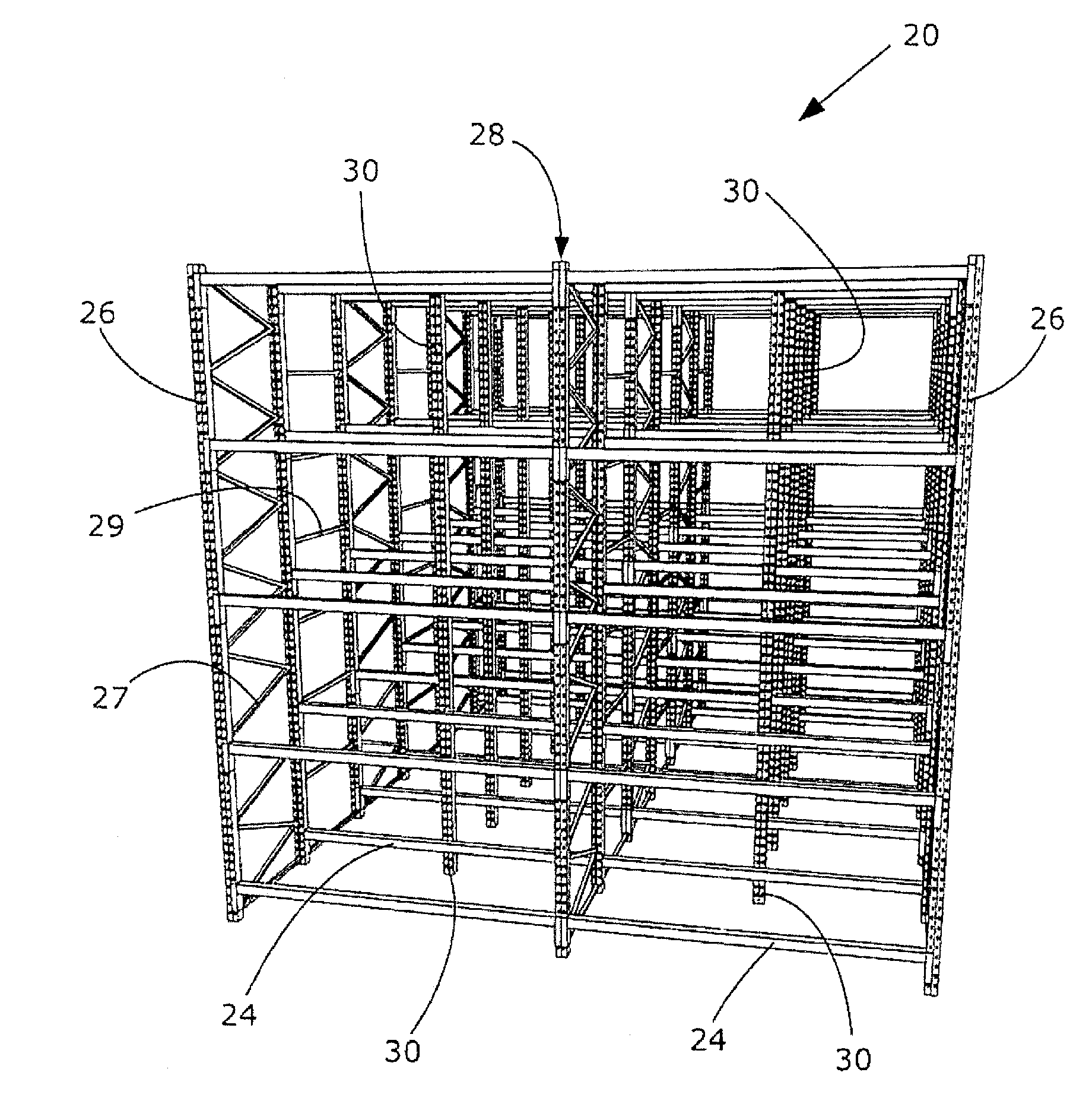

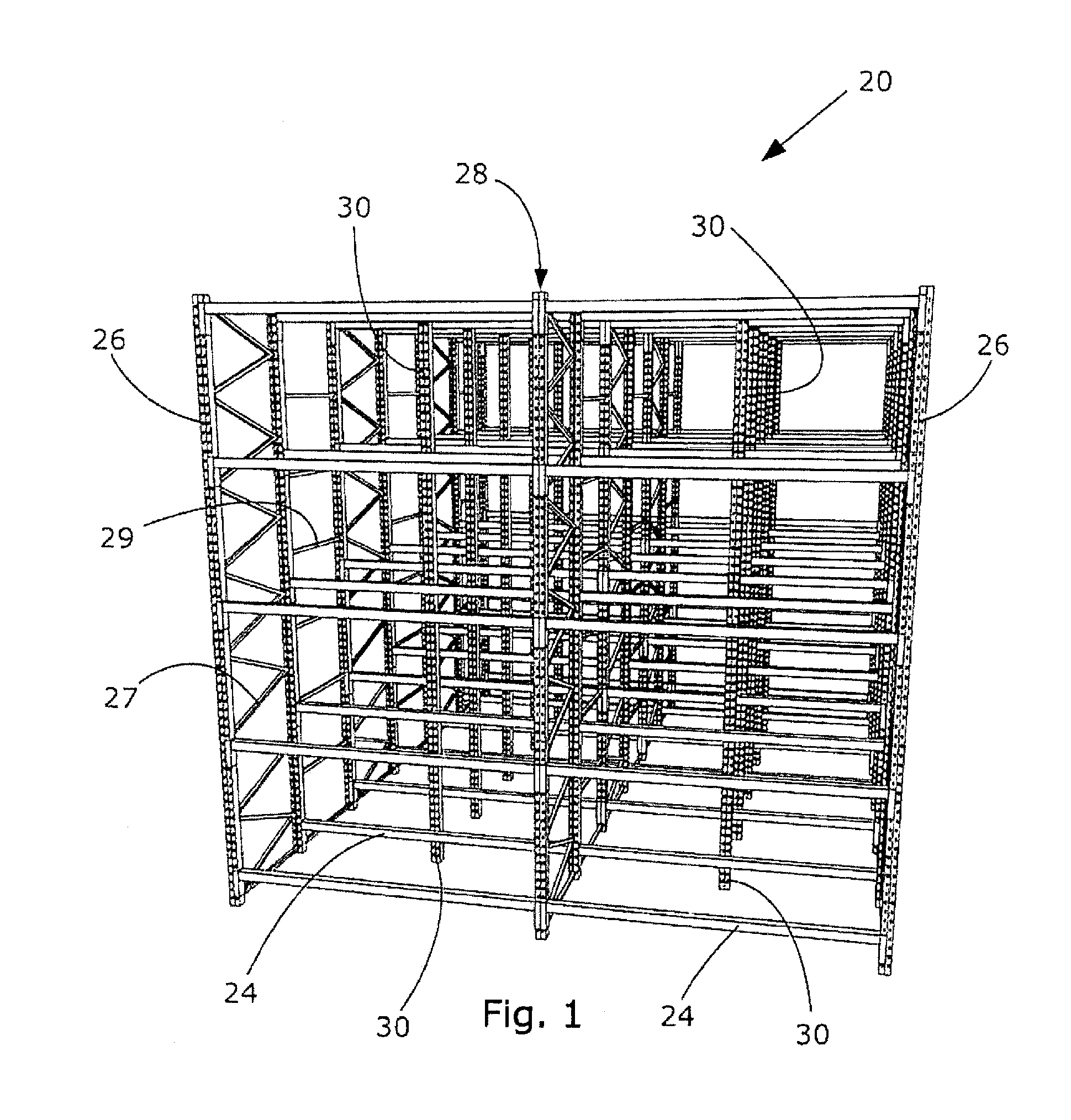

[0073]Referring now to the drawings there is illustrated in FIG. 1 a rackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com