Product early-fault root cause recognition method based on fuzzy data processing

A technology for early faults and fuzzy data, applied in electrical digital data processing, special data processing applications, manufacturing computing systems, etc., can solve problems such as the disadvantage of accurately locating the root cause of early faults, hindering targeted reliability, and difficult quantitative analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

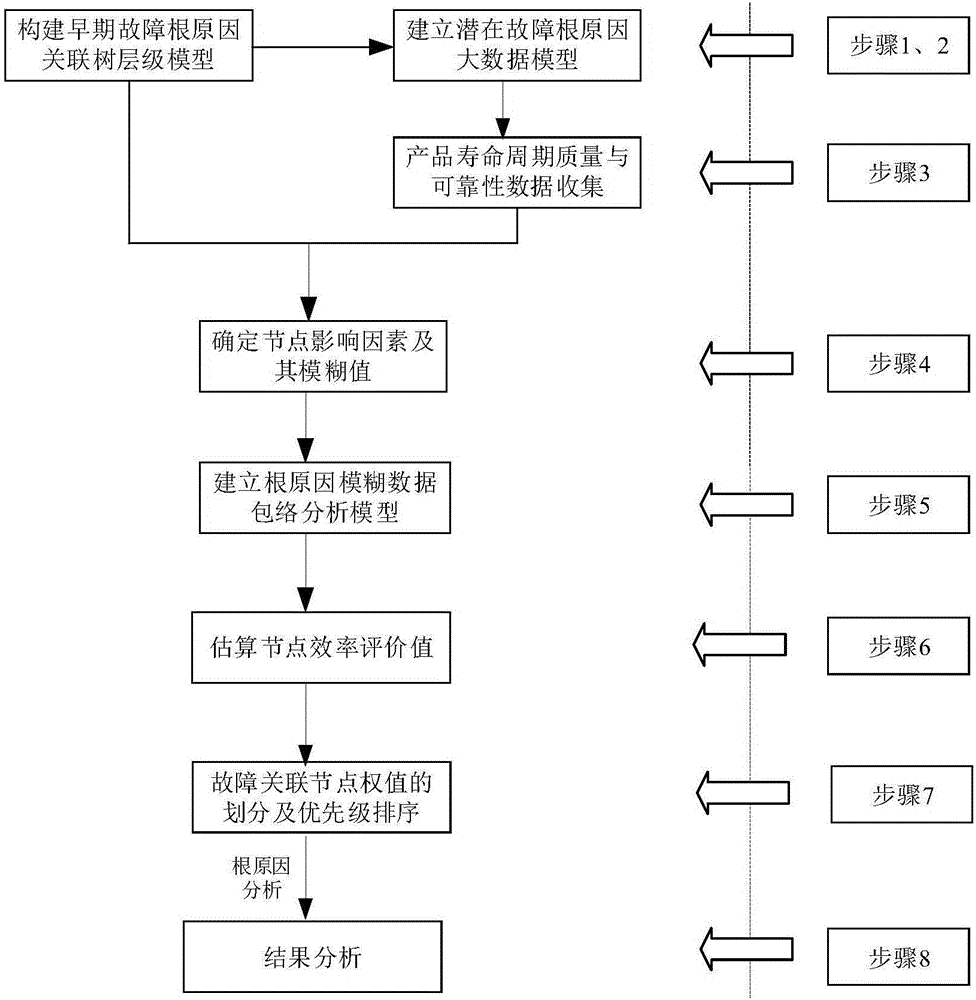

[0078] The present invention is based on the association tree and fuzzy data envelopment analysis method for identifying the root causes of early failures of products, see figure 1 As shown, the specific steps are as follows:

[0079] Step 1. Build a hierarchical model of root causes of product early failures

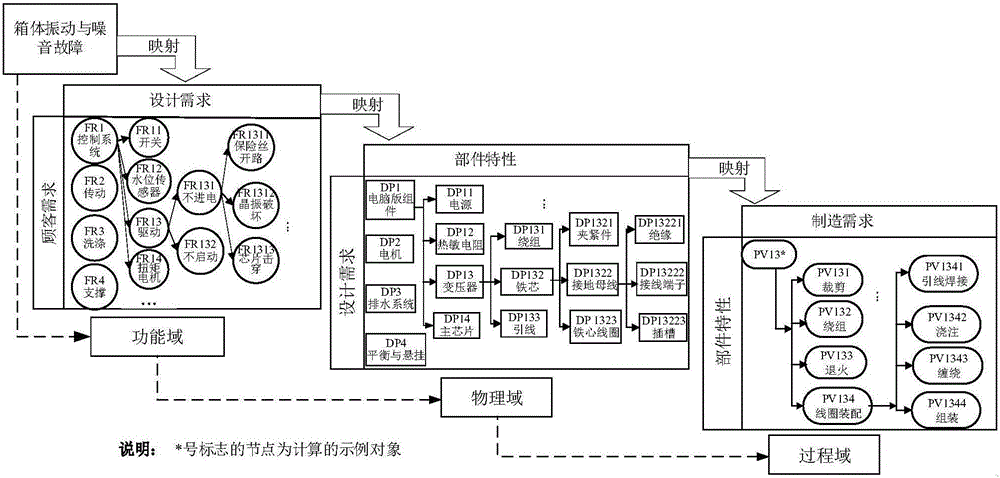

[0080] Using the axiomatic domain mapping theory to build a hierarchical model of early fault root cause correlation tree, and construct a hierarchical fault correlation tree model from design to manufacturing of functional domain (FR), physical domain (DP) and process domain (PV), such as figure 2 shown.

[0081] Step 2, Build a data model of potential root causes of failures

[0082] In actual engineering applications, product failures are caused by many different reasons, such as unqualified products in the product design stage, physica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com