Method for preparing fructooligosaccharide by taking waste molasses as raw material

A technology of fructooligosaccharides and waste molasses, applied in the direction of fermentation, can solve the problems of prolonging the production cycle of products, harsh working environment, high temperature liquid overflowing and splashing, etc., to achieve good resource protection and comprehensive utilization, speed up adjustment and industrial upgrading , the effect of reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

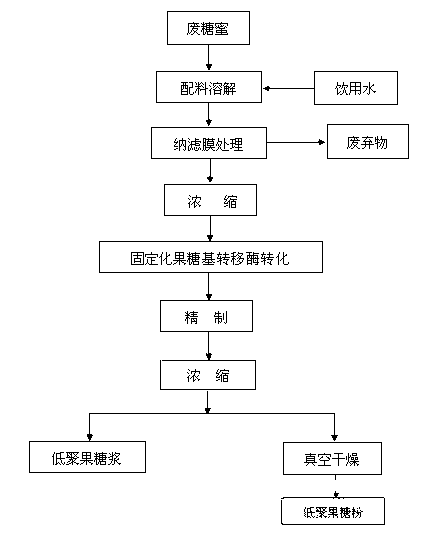

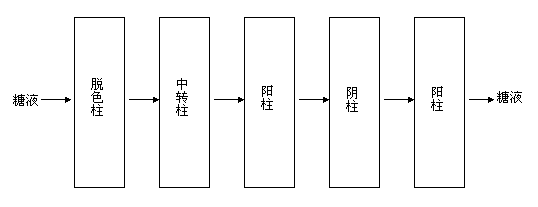

[0018] Mix waste molasses and drinking water into a solution with a concentration of 15% in a certain proportion, and filter it through a nanofiltration membrane. The operation is performed at an average operating temperature of 34~45°C, inlet pressure and outlet pressure of 5~8bar and 4~6bar, respectively. Under certain conditions, when the membrane flux is less than or equal to 2LMH, the feeding is stopped, and the membrane is backwashed with dilute lye. After the dialysate is concentrated with a mass fraction of 52%, add fructosyltransferase, adjust the pH to 5.0, keep warm at 38°C for 10 hours, filter, and use the improved continuous decolorization interchange process to carefully refine the sugar solution. Decolorization and separation process conditions: The pH of the sample solution is 5.0, the sample concentration is 30%, and the sample flow rate is 2. BV / h, that is, 3ml / min. The light transmittance of the column material liquid is ≤85%, and when the conductance of the...

Embodiment 2

[0020] Mix waste molasses and drinking water into a solution with a concentration of 20% in a certain proportion, and filter it through a nanofiltration membrane. The operation is performed at an average operating temperature of 35~45°C, inlet pressure and outlet pressure of 5~8bar and 4~6bar, respectively. Under certain conditions, when the membrane flux is less than or equal to 2LMH, the feeding is stopped, and the membrane is backwashed with dilute lye. The concentrated dialysate solution with a mass fraction of 50% was added with fructosyltransferase to adjust the pH to 5.5, kept at 38°C for 20 hours, filtered, and the improved continuous decolorization interchange process was adopted to carefully refine the sugar solution, decolorization and separation process conditions: The pH of the sample solution is 5.5, the sample concentration is 35%, and the sample flow rate is 2.5 BV / h, that is, 4ml / min. The light transmittance of the material liquid is ≤85%, and when the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com