Method for manufacturing root portion of fan blade with square embedded bolt sleeve

A technology of pre-embedding bolts and fan blades, which is used in mechanical equipment, wind turbines, wind turbine components, etc., can solve the problems of pulling out the bolt sleeve and harmful blade operation, and achieves increased strength, high firmness, and reasonable process design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. A method for preparing the root of a fan blade with a square pre-embedded bolt sleeve, comprising the following steps:

[0040] a. Preparation of square bolt sleeves:

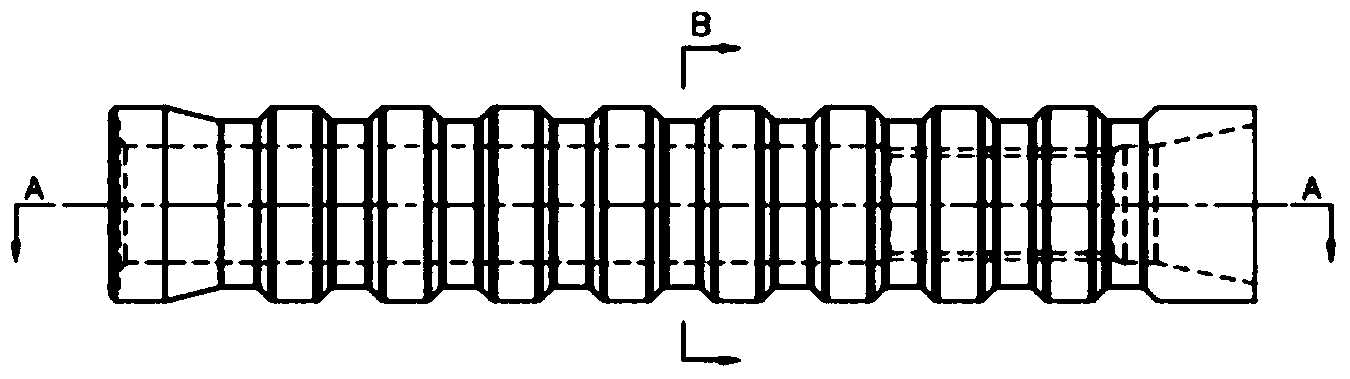

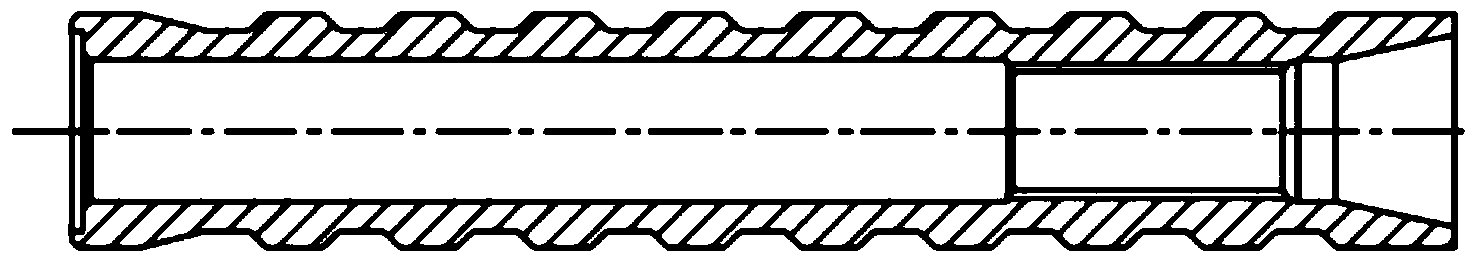

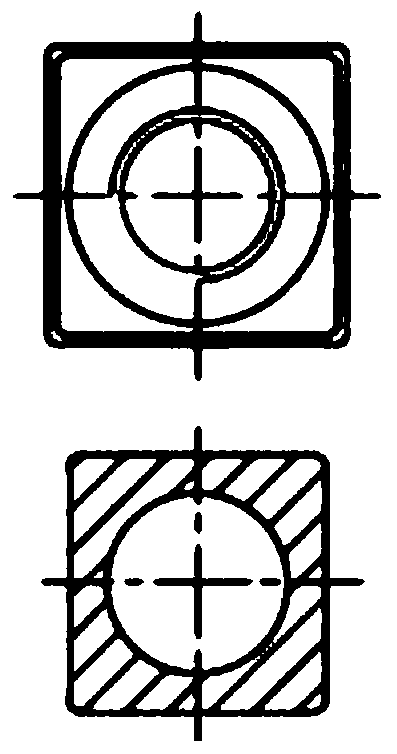

[0041] Choose circular bar or metal material with square cross-section as the processing substrate, heat the circular or square processing substrate, then put it into the mold with the reverse shape of the square bolt sleeve, apply external load pressure, and process it into a surface There is a square bolt sleeve with horizontal or threaded grooves, and then the surface of the square bolt sleeve is sandblasted to prepare a square bolt sleeve (1); as Figures 1 to 3 Shown:

[0042] b. Wrap the roving (2) in the surface groove of the square bolt sleeve (1);

[0043] c, then install a steel flange (4) for positioning the square bolt sleeve (1) at the root of the blade mold (3);

[0044] d. Lay a release cloth inside the root of the blade mold (3), and then lay a dry glass fiber cloth (5) of a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com