Full BF gas hot blast furnace

A technology of blast furnace gas and hot blast stove, applied in air heaters, combustion chambers, combustion methods, etc., which can solve the problems of increased floor area, insufficient coke oven gas, and lack, etc., to achieve easy installation and replacement, and small floor space , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

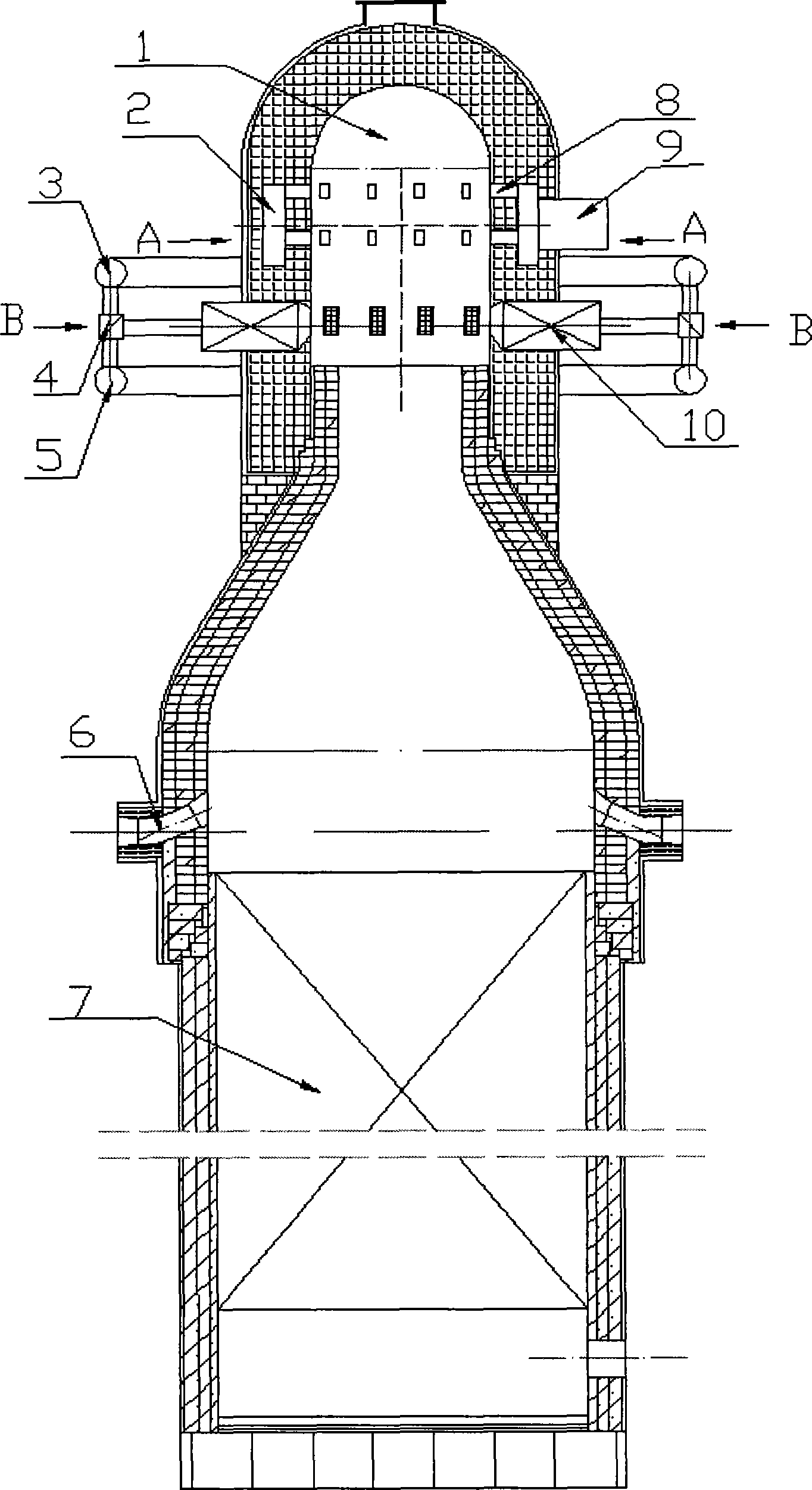

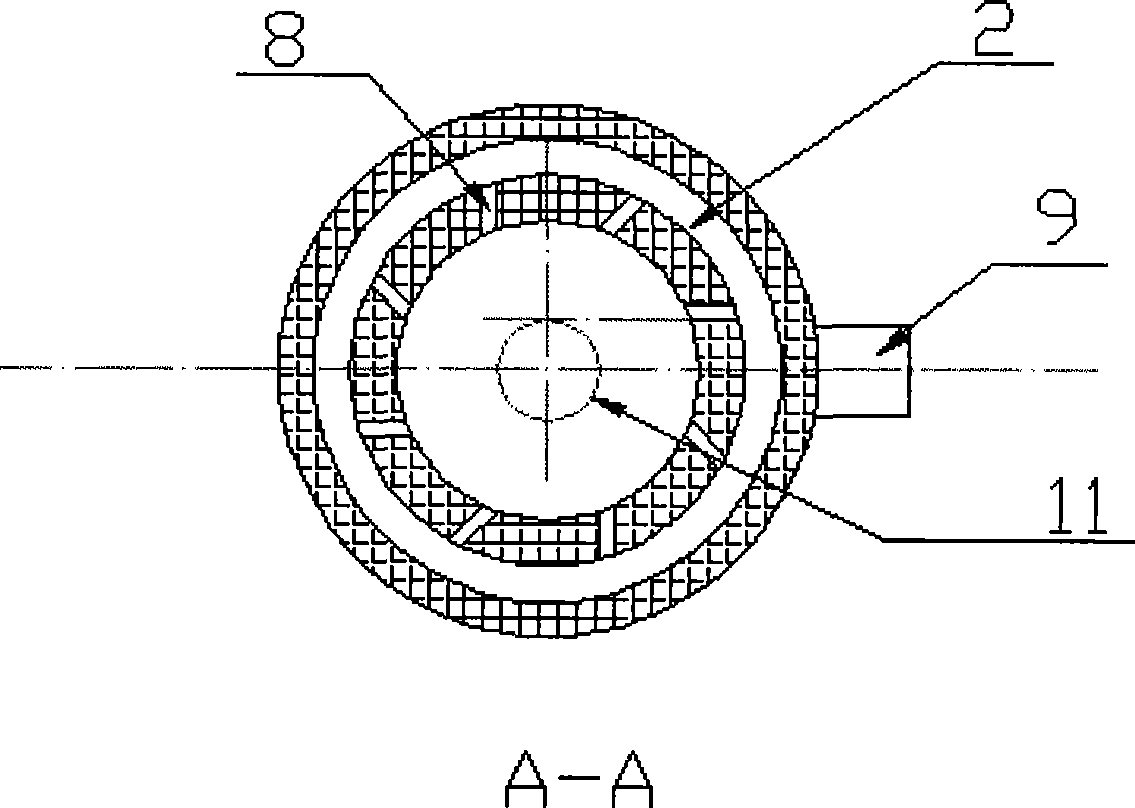

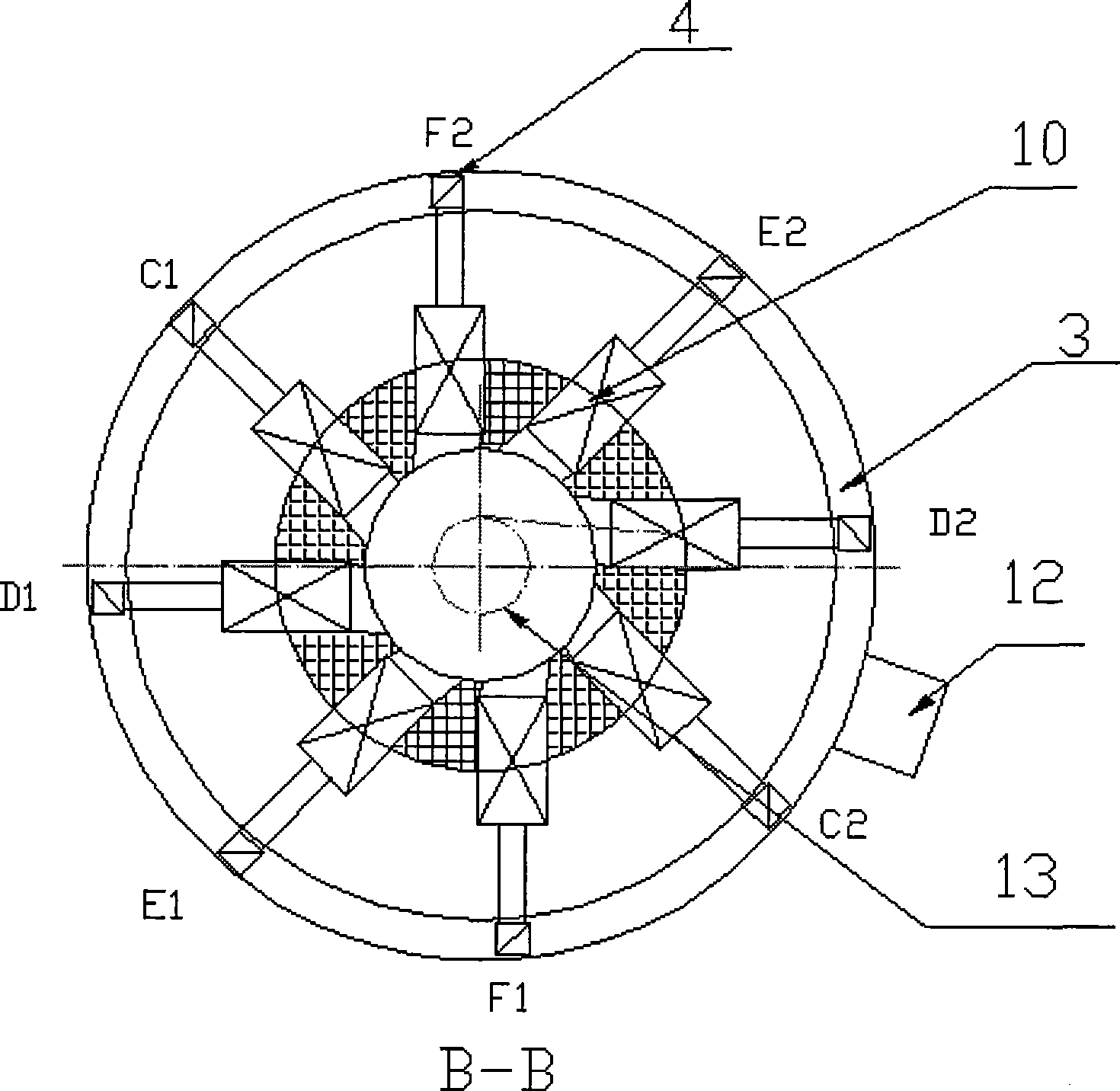

[0030] Figure 1 ~ Figure 4 It is a specific embodiment of the present invention that burns blast furnace gas high wind temperature hot blast stove

[0031] The hot blast stove of the present invention only needs one to realize the full combustion of blast furnace gas to reach a high blast temperature of 1250-1600°C. Two to four hot blast stoves 14 work together, one is burning and the other is blowing air. It can be two burns and one delivery, two burns and two deliveries, or three burns and one delivery. In the hot blast stove 14 in the combustion period, 90-95% of the flue gas at the tail passes through the separate heat pipe heat exchanger 21 to preheat the gas after dry dust removal to 150-250°C, and the gas passes through the gas pipeline 17 to reach the gas inlet 9. Enter the combustion chamber 1 from the gas nozzle 8 in the tangential direction of the tangential circle 11 through the gas loop, and the air blower 23 mixes the air with 5-10% of the flue gas at the tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com