Patents

Literature

100results about How to "Realize parameterization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

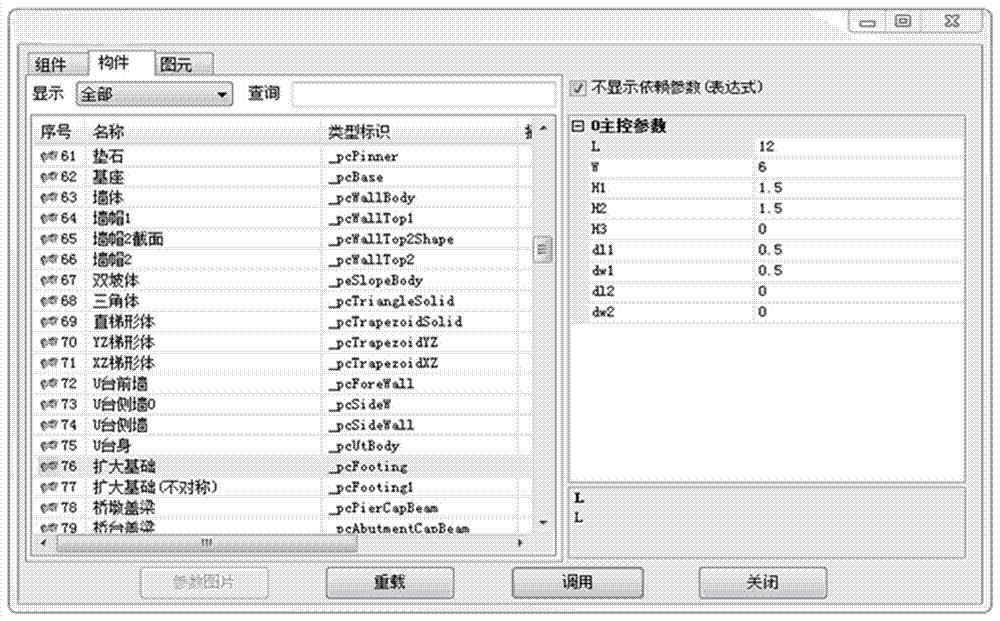

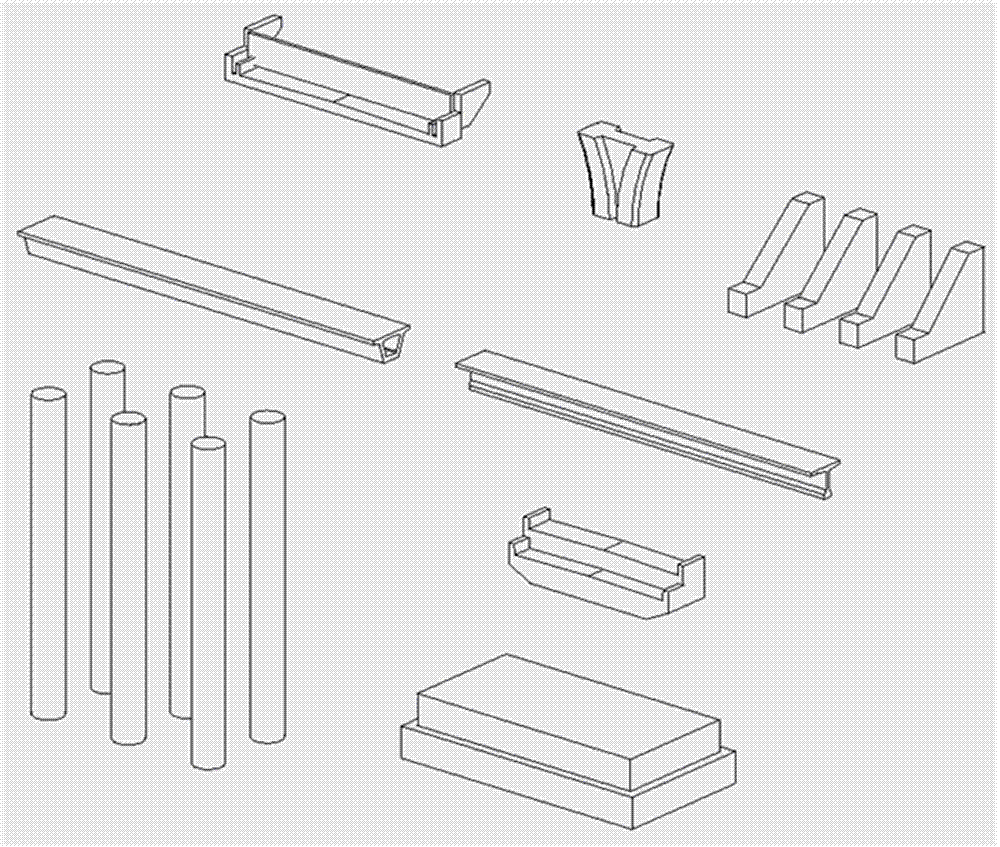

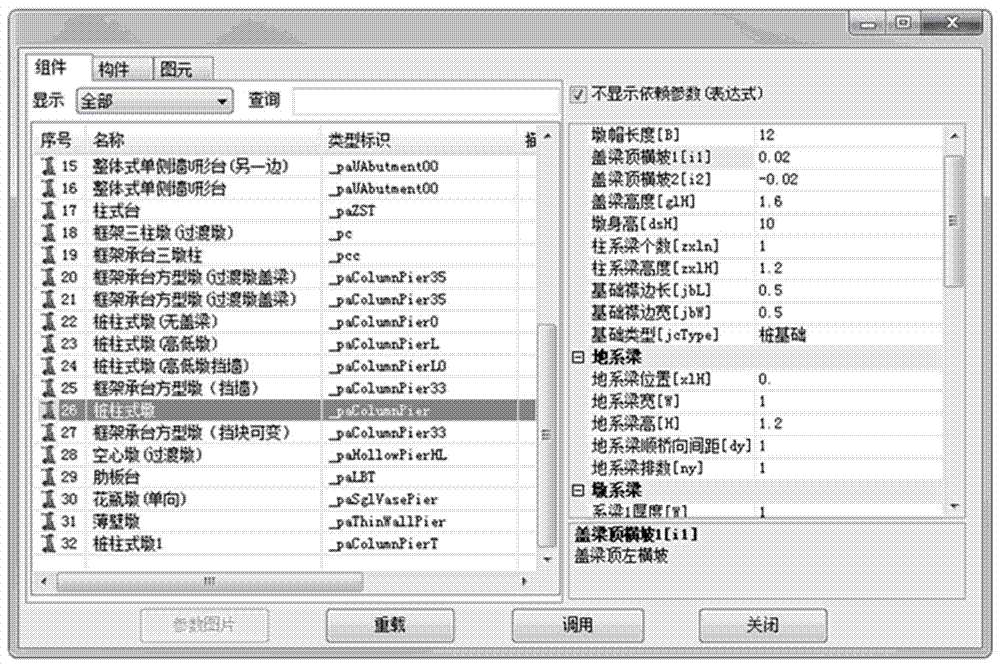

Bridge three-dimensional model construction method based on BIM

InactiveCN106934163ARealize parameterizationAchieve standardizationGeometric CADDesign optimisation/simulationComputer scienceTemplate library

The present invention discloses a bridge three-dimensional model construction method based on the BIM. The method comprises the following steps: dividing objects of an whole structure of the bridge, and classifying the objects of the bridge in a normative manner; subdividing the bridge components into elements and primitives, parameterizing the elements and primitives, and formulating a parameter table corresponding to the geometric dimensions; carrying out assembly and positioning on the three-dimensional model of the bridge components, determining and defining element control points and relative spatial position relationships, assembling the elements into components, storing the components into an component template library, and establishing component control points; extracting three-dimensional route information of the project, and determining stake marks and the design elevation of the route; and assembling the component three-dimensional model, based on the route information, using positioning parameters to determine the location of the component model, and calling the type method, so that parametric assembly can be automatically carried out between components. According to the method disclosed by the present invention, by optimizing the bridge model, parameterization and standardization of the bridge components are realized, the modeling time is shortened, and the design efficiency and quality are improved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

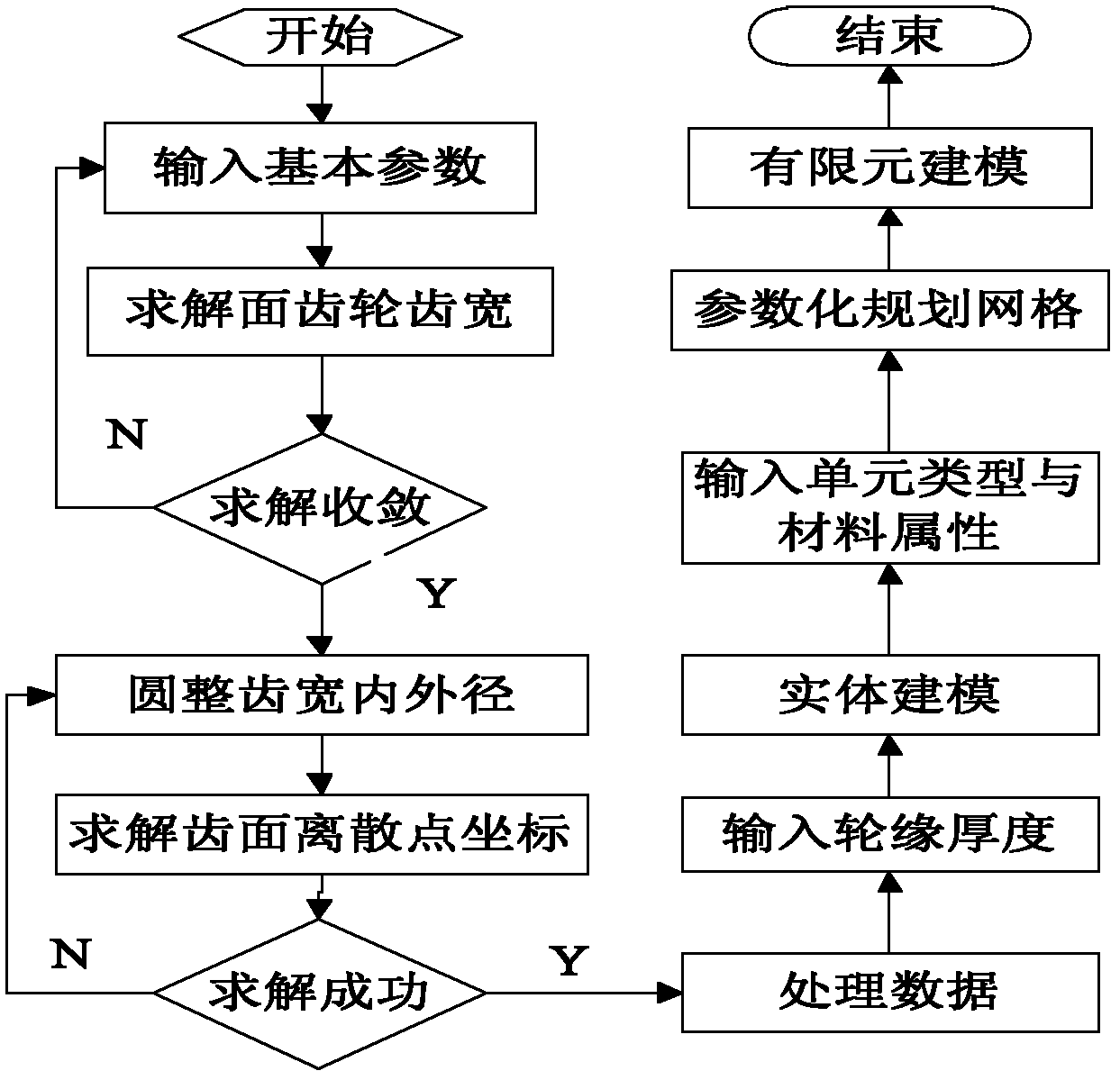

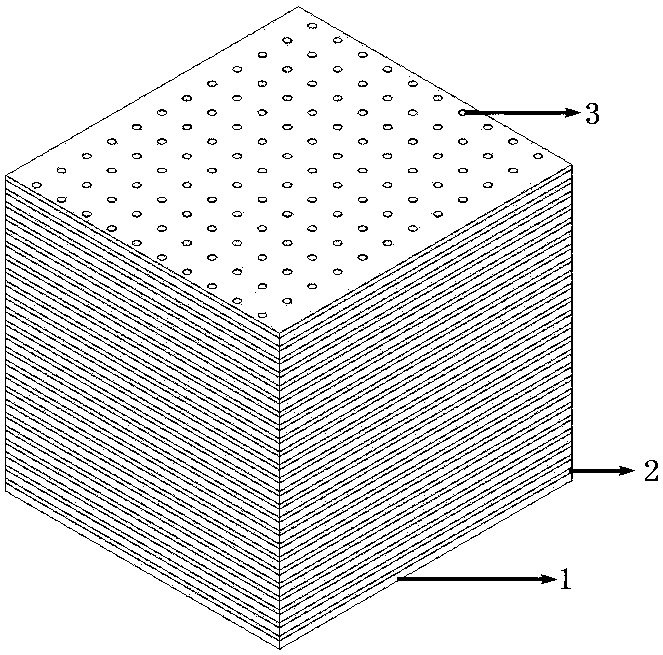

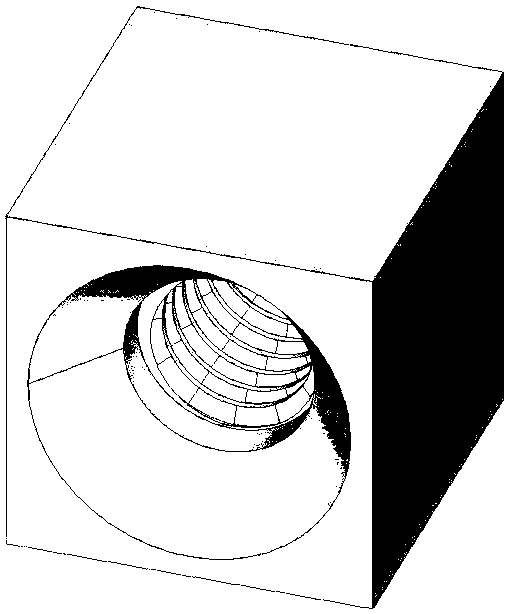

Parametric modeling method of face gear teeth

InactiveCN102567596AQuality improvementReduce workloadSpecial data processing applicationsElement modelPhysical model

The invention discloses a parametric modeling method of face gear teeth, comprising the following steps: first, calculating tooth surface numerical value of a face gear; then processing tooth surface discrete points coordinate data to directly read in the data to ANSYS environment; and parametrically establishing a gear tooth finite element model after parametrically establishing a gear tooth physical model, thereby obtaining a parametric finite element model. By mixed programming of Matlab and APDL (parametric design language), the method combines functions of face gear teeth width design, tooth surface stimulation, physical modeling, finite element modeling and the like, and realizes parameterization and intellectualization of face gear teeth design and modeling, high quality of finite element model, reduction of workload of designers and improvement of work efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

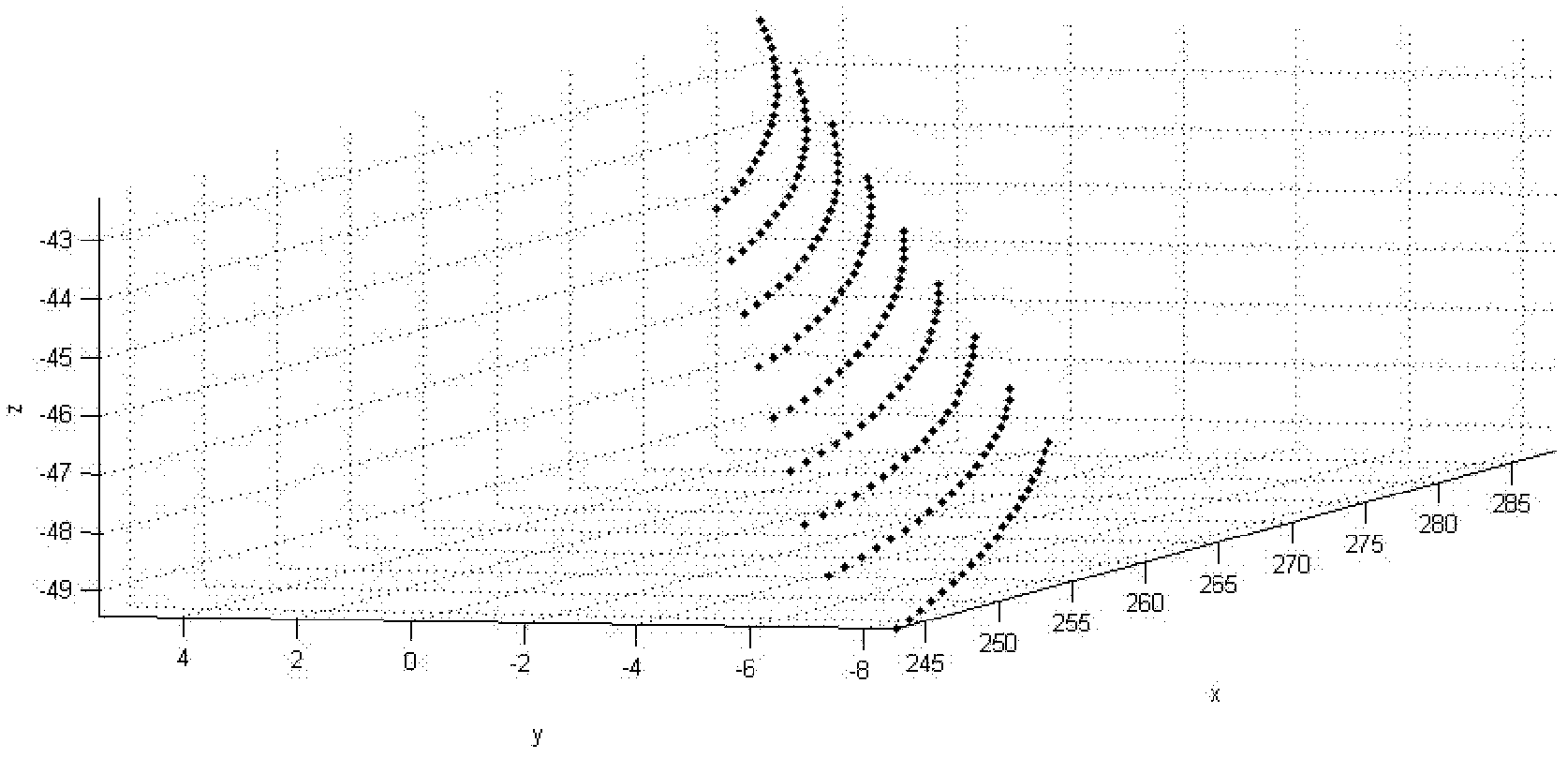

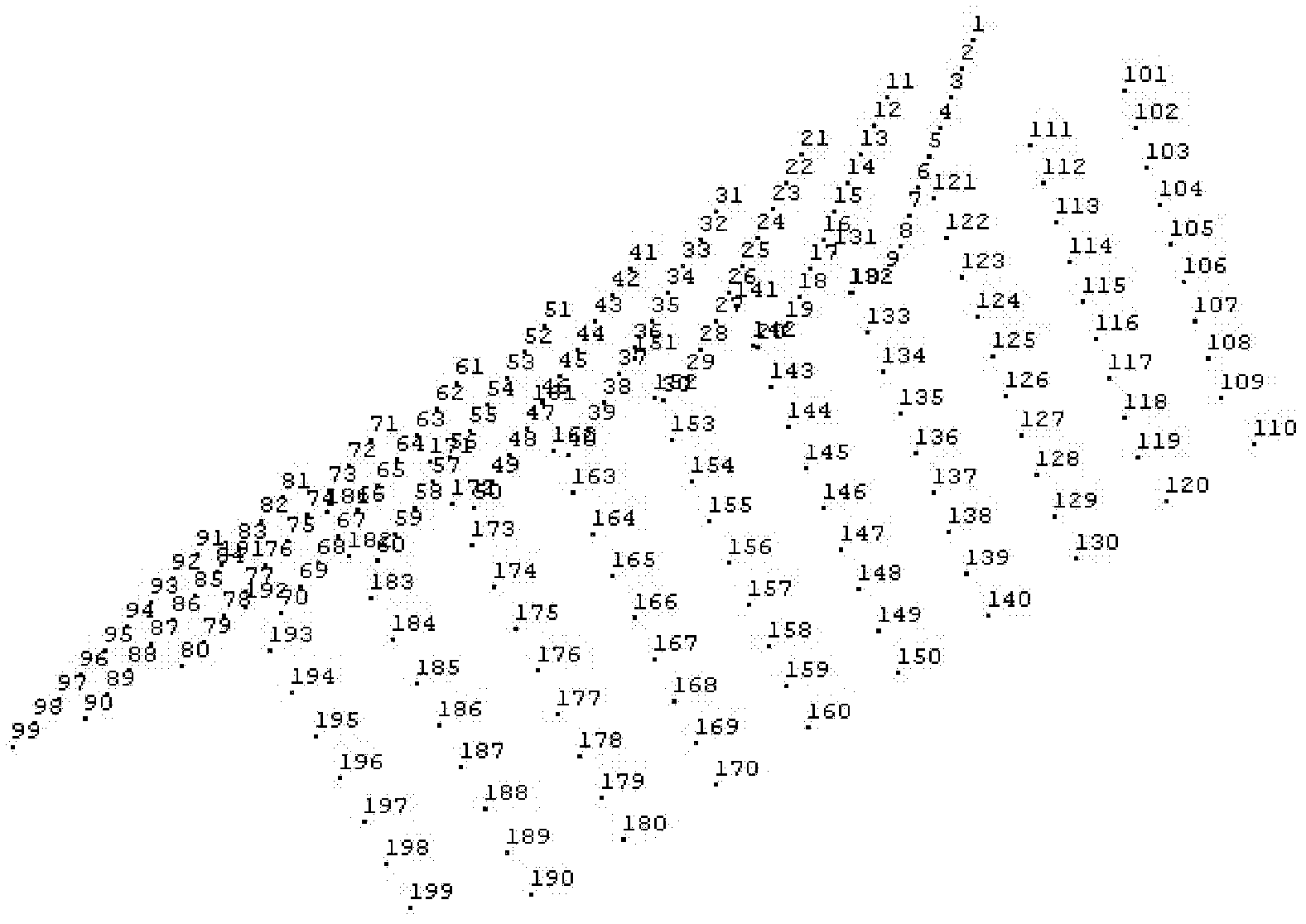

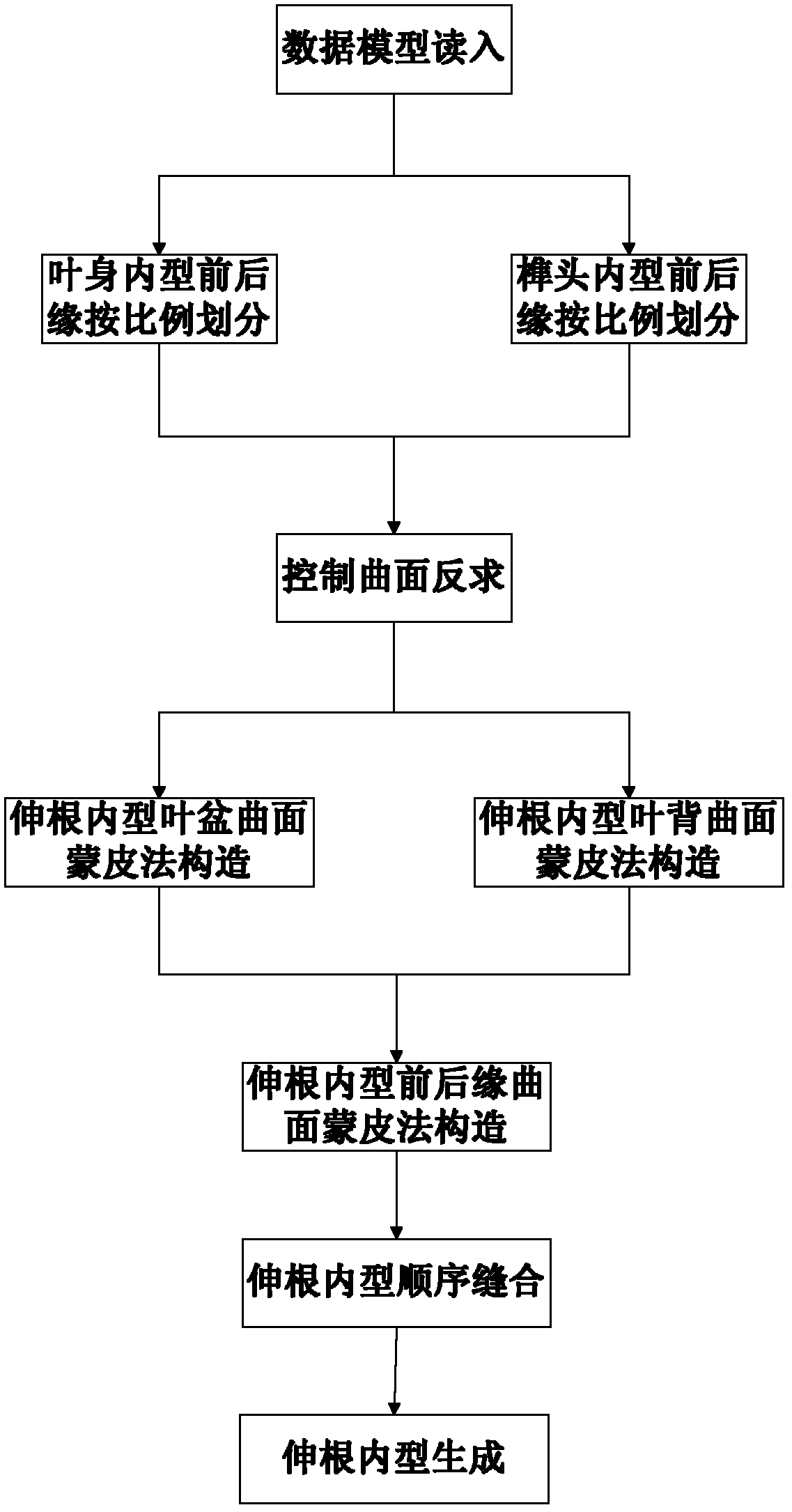

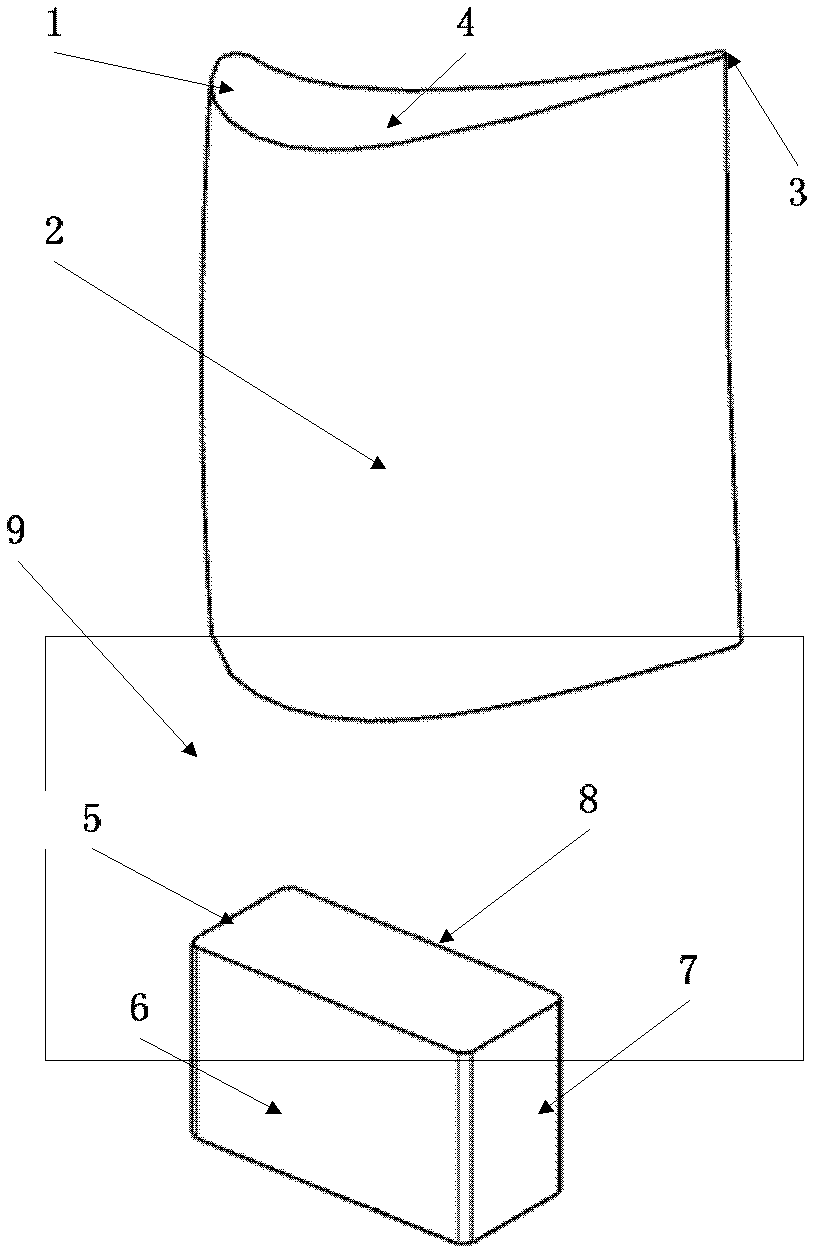

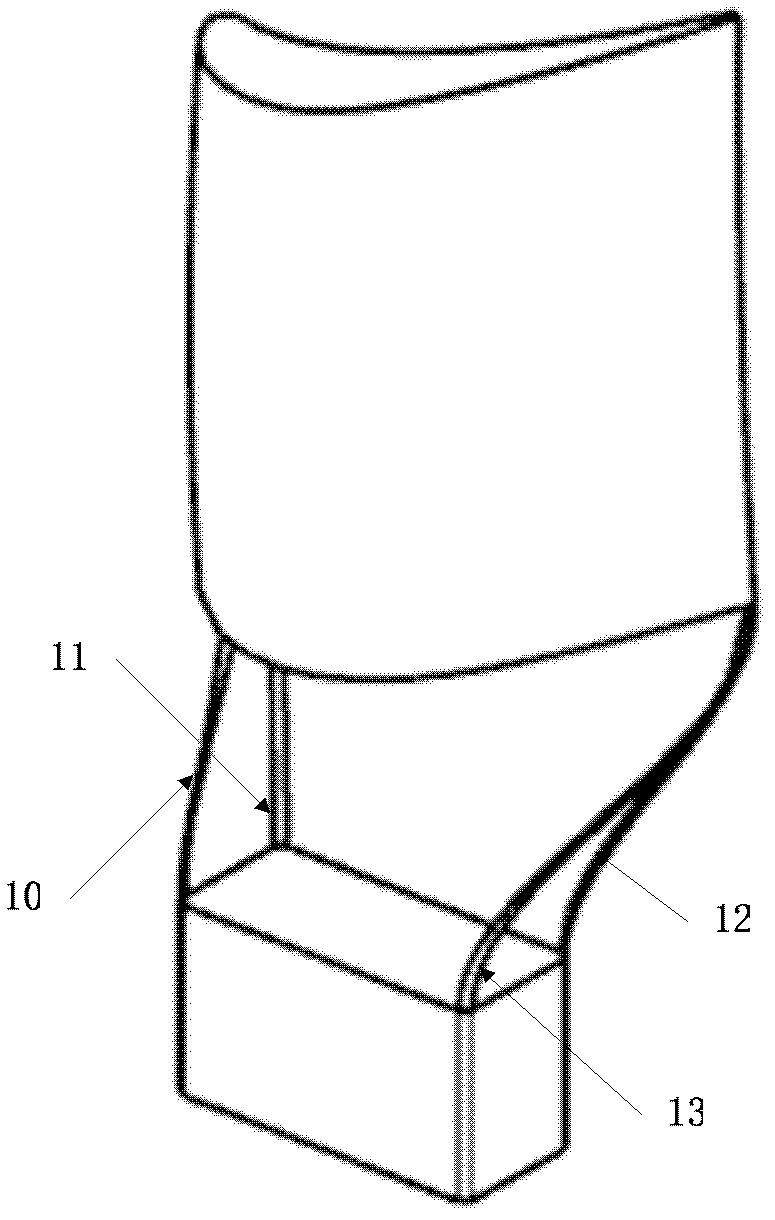

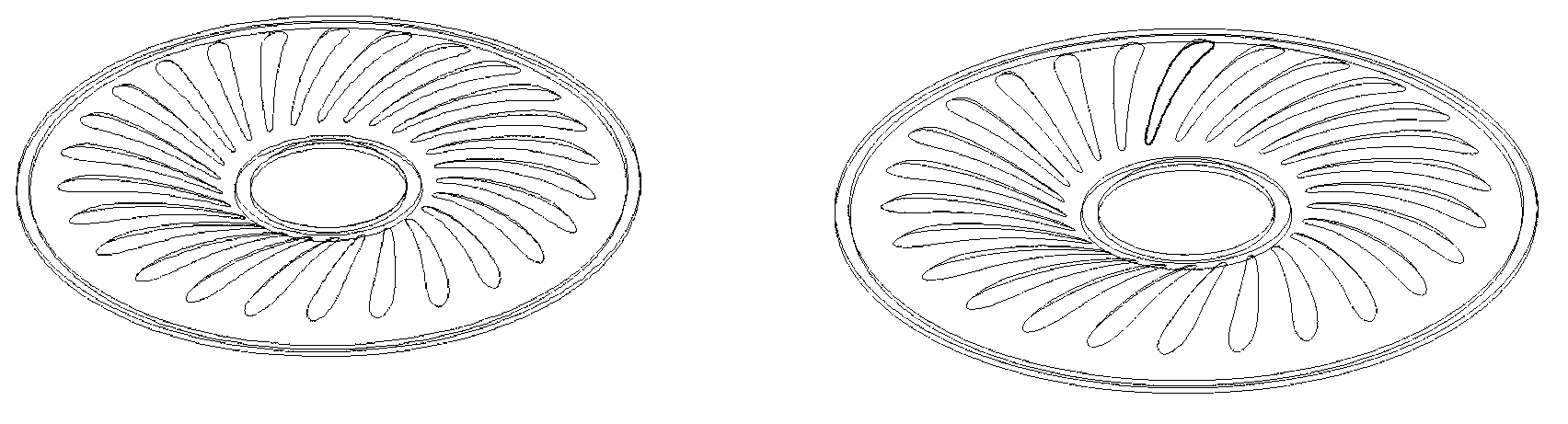

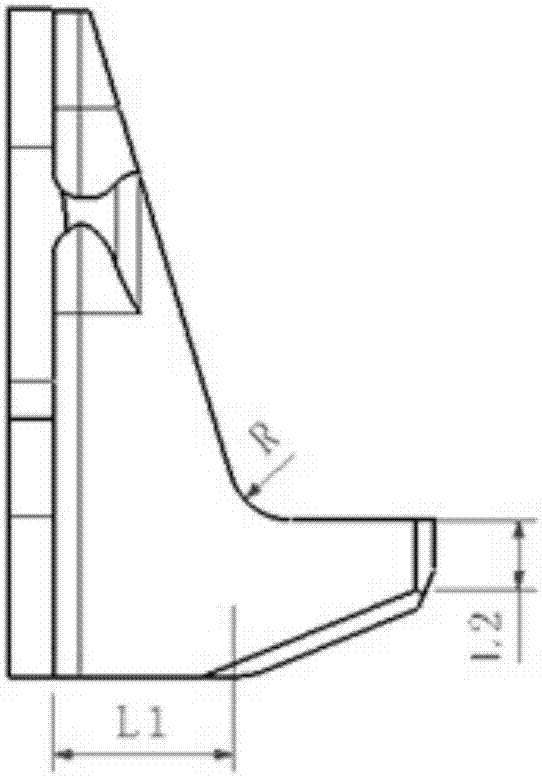

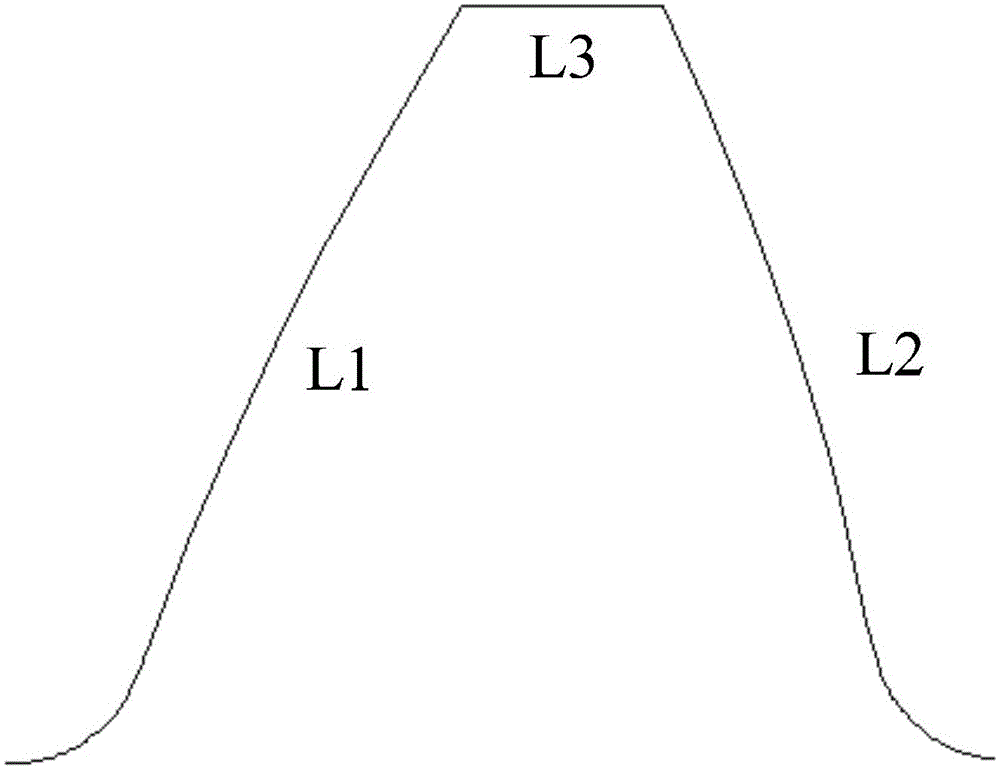

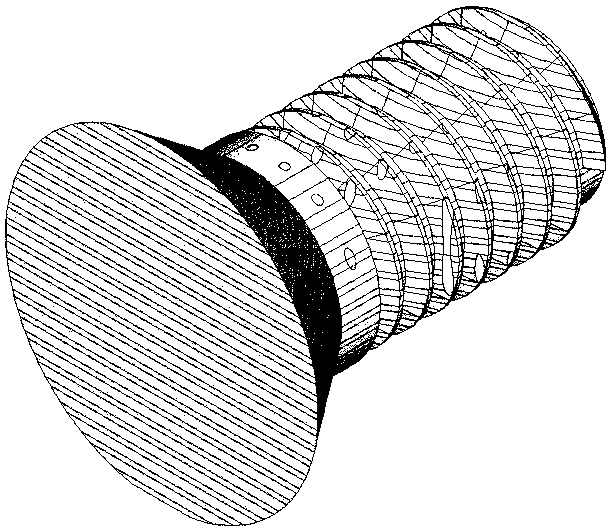

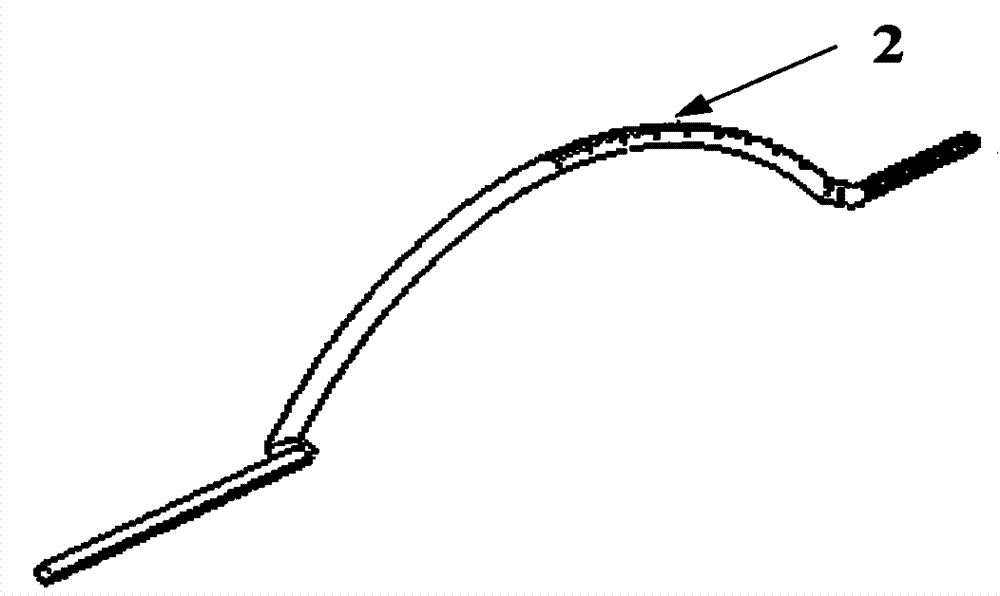

Parameterization modeling method for turbine blade root extension segment profile

InactiveCN102637233AReduce inconvenienceRealize parameterizationBlade accessoriesMachines/enginesContinuationTurbine blade

The invention provides a parameterization modeling method of a turbine blade root extension segment profile. The method comprises the steps of firstly, dividing a blade body profile curved surface of a blade and a tenon profile curved surface, then dividing the divided front edge and rear edge curved surfaces of a blade body and the front edge and rear edge curved surfaces of a tenon, constructing a blade basin control curved surface and a blade back control curved surface, and finally constructing and sewing the blade basin and blade back control curved surfaces, the blade body profile curved surface and the tenon profile curved surface into a root extension profile extended curved surface. Through the use of the method, at least G1 continuation is achieved at the connection positions among the root extended profile, a blade body profile and a tenon profile, and G2 continuation can be achieved at the interior, thus being capable of generating a segment of a smoothier root extended profile. Furthermore, four B sample strip control curved surfaces generated through reverse calculation of a transition section is changed through changing the proportion of the front edge and rear edge curved surfaces so as to control section curves and ridge lines of the blade basin curved surface and the blade back curved surface of the root extended profile, thus adjusting the whole root extended profile so as to obtain a satisfactory shape.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

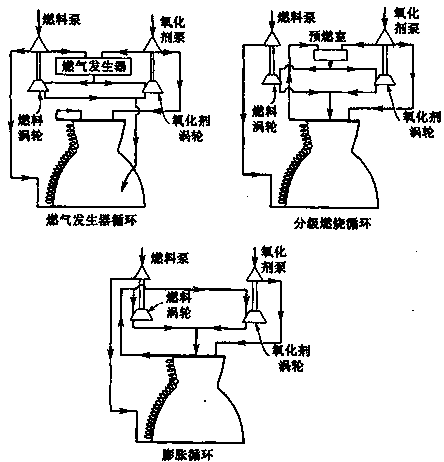

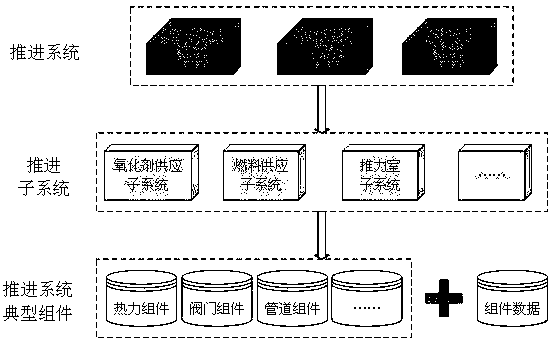

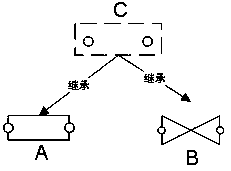

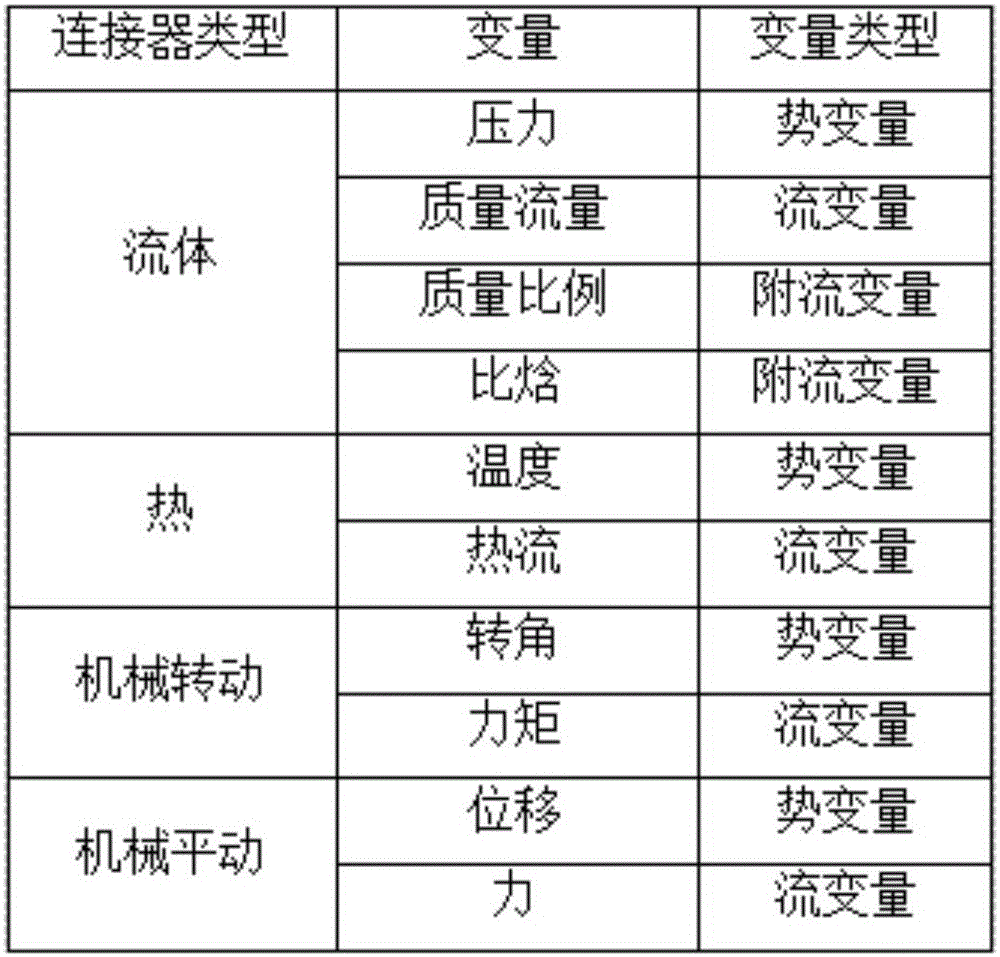

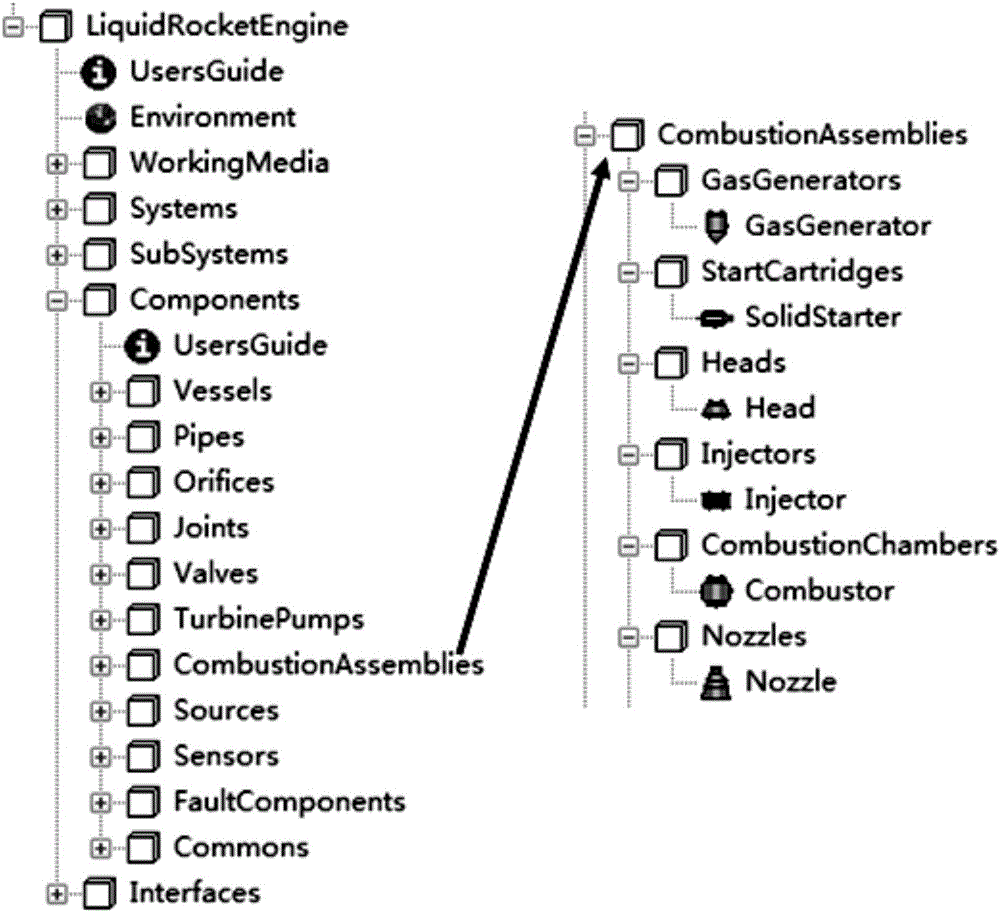

Dynamic analysis method for spacecraft propulsion system based on Modelica model

InactiveCN107357961AReduce the difficulty and complexity of buildingReduced modeling effortGeometric CADSustainable transportationReusabilitySpacecraft

The invention discloses a dynamic analysis method for a spacecraft propulsion system based on a Modelica model. The method comprises the following steps: 1) determining a model target; 2) constructing a concept model; 3) decomposing a system; 4) building a basic model; 5) designing a connector; 6) establishing an assembly model; 7) building a medium model; 8) building a system model; 9) making simulated analysis. The dynamic analysis method combines a modeling simulation theory of the spacecraft propulsion system with a system Modellica technology and employs a statement method directed at objects to build a dynamic model of the propulsion system. Due to non-causal characteristics, modeling engineers do not need to decouple the propulsion system without assigning input and output variants of the model and the equation solving sequence. During solving, a simulation system can determine the equation solving sequence according to the environment of equation system data flows. Therefore, modeling difficulty and complexity of a dynamic model of the propulsion system are effectively reduced. The reusability and expansibility of the model are improved.

Owner:苏州同元软控信息技术有限公司

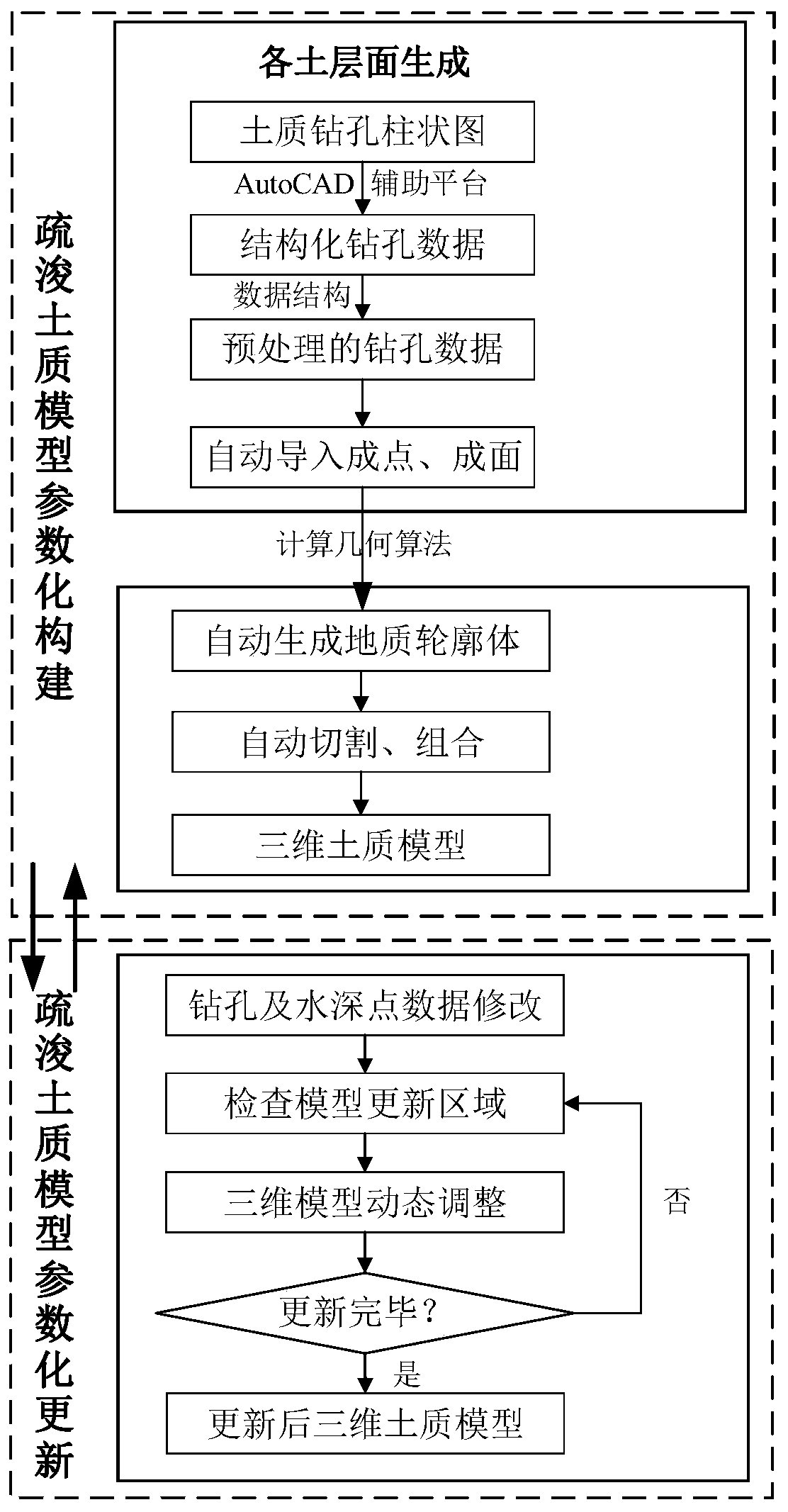

Parameterized three-dimensional geological modeling method and system and information data processing terminal

InactiveCN110689615ARealize parameterizationOvercome operational complexity3D modellingComputational scienceAlgorithm

The invention discloses a parameterized three-dimensional geological modeling method and system and an information data processing terminal, and belong to the technical field of geological modeling. The method is characterized in that the parameterized three-dimensional geological modeling method comprises the following steps: 1, according to drilling data of field exploration, arranging the drilling data into a database table according to a certain data format; 2, automatically importing the sorted data into a modeling space; 3, according to a pre-programmed program, automatically forming a surface in a point-to-point manner, and generating each geological layer; 4, determining an outer boundary in a parameterized manner, creating an outer contour of the geologic model, and automaticallyshearing and combining; and 5, according to the changed drilling data points, executing the steps again, and completing parameterized updating creation of the model. By the adoption of the technical scheme, the complex geological modeling process is parameterized, the labor amount of traditional manual modeling is reduced in a computer programming algorithm mode, and geological modeling is more intelligent.

Owner:CCCC TIANJIN ECO ENVIRONMENTAL PROTECTION DESIGN & RES INST CO LTD

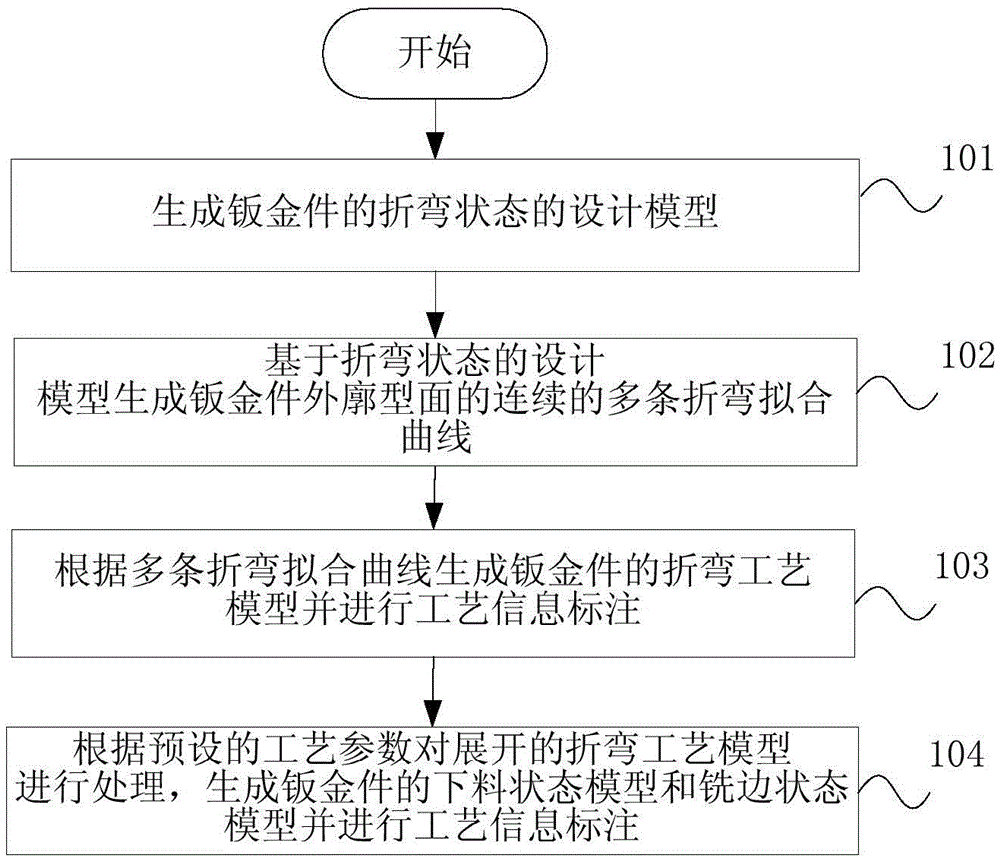

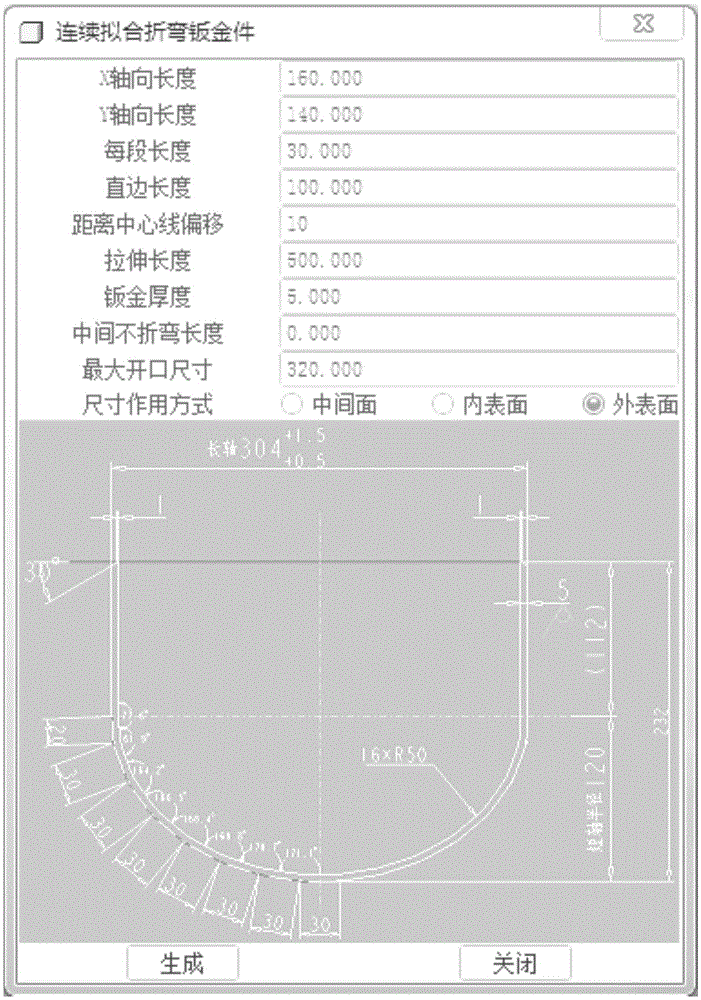

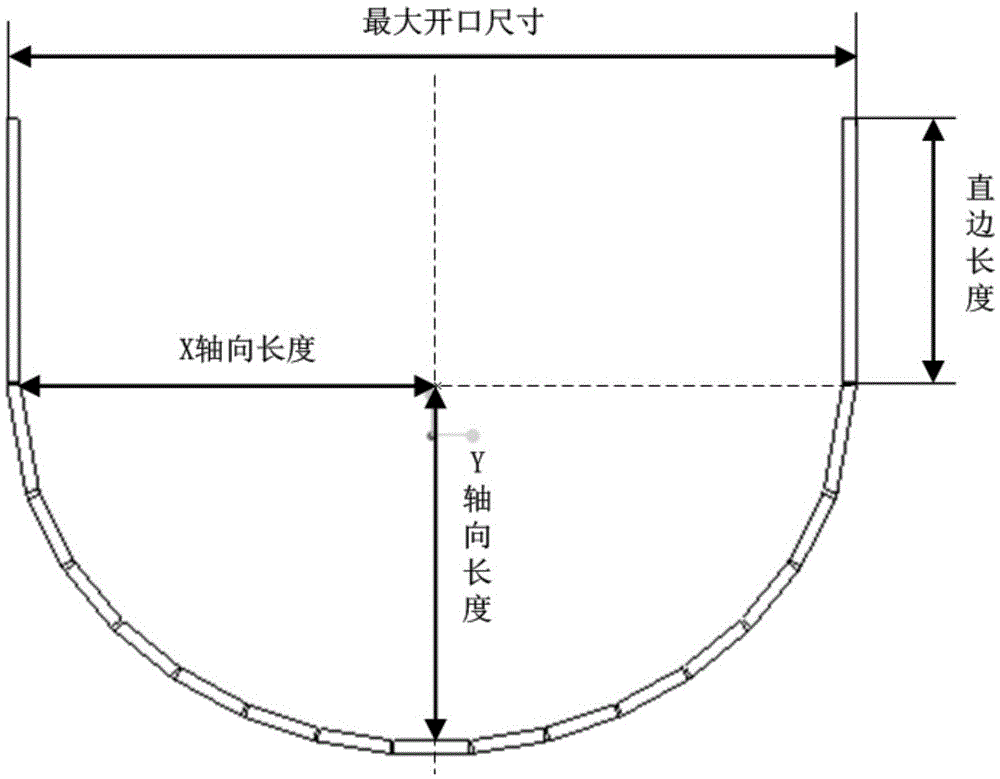

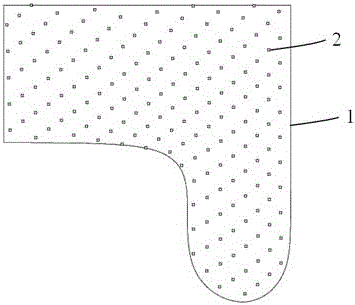

Process model generation method and apparatus for sheet metal process

ActiveCN105550388ARealize automatic fitting lineRealize parameterizationComputer aided designSpecial data processing applicationsState modelSoftware engineering

The invention discloses a process model generation method and apparatus for a sheet metal process. The method comprises the steps of generating a design model of a bending state of a sheet metal part; based on the design model of the bending state, generating multiple continuous bending fit lines of an external profile of the sheet metal part; according to the bending fit lines, generating a bending process model of the sheet metal part and performing process information labeling; and according to preset process parameters, processing an expanded bending process model to generate process state models of the sheet metal part, and performing process information labeling, wherein the process state models include a discharge state model and an edge milling state model. According to the process model generation method and apparatus, automatic fit lineation of the sheet metal part can be realized; the process state models including the bending process model, the discharge state model, the edge milling state model and the like can be automatically generated and the process information labeling is performed; the parameterization, normalization and standardization of a technological design process of the sheet metal part are realized; and the technological design efficiency is improved, so that the workload of manual lineation is reduced and the preparation cycle of a sheet metal manufacturing process is shortened.

Owner:XCMG CONSTR MACHINERY

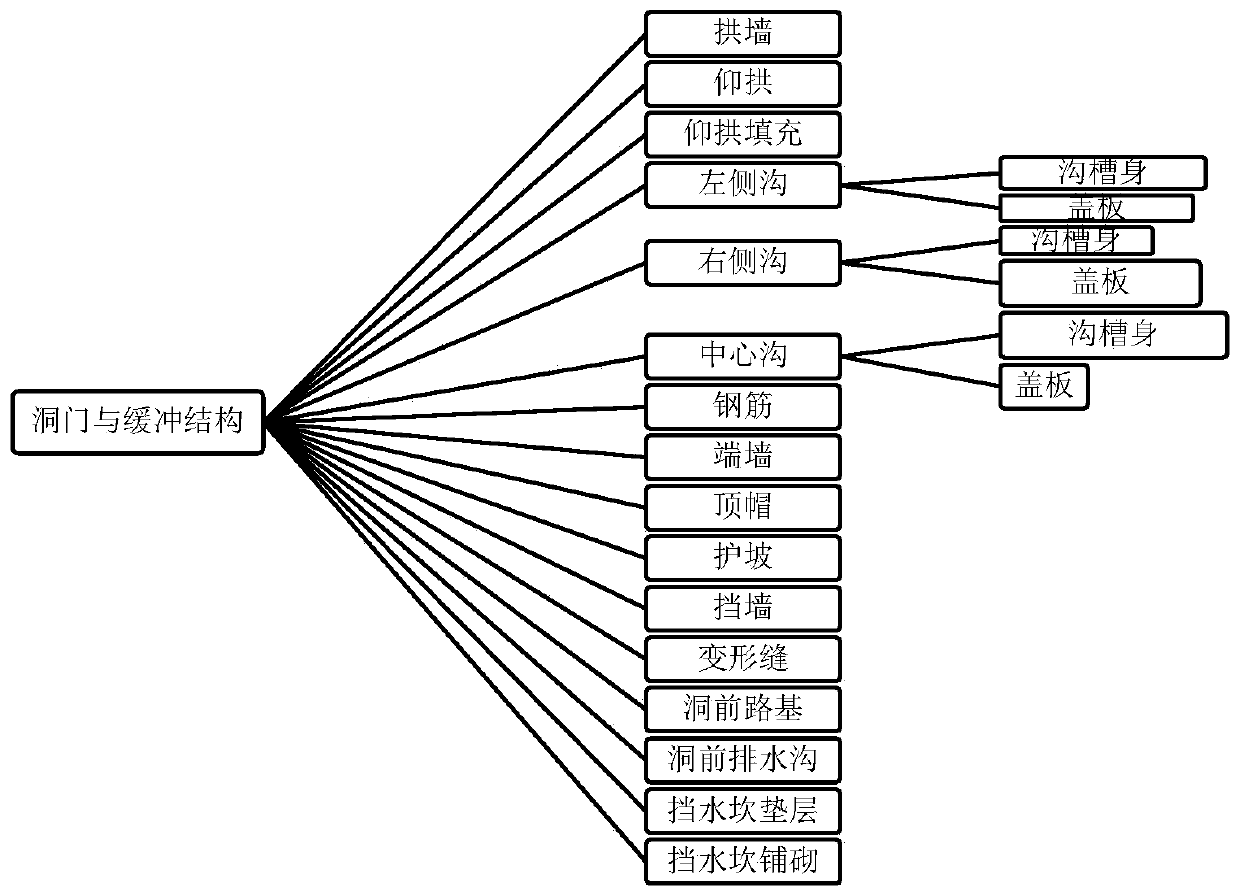

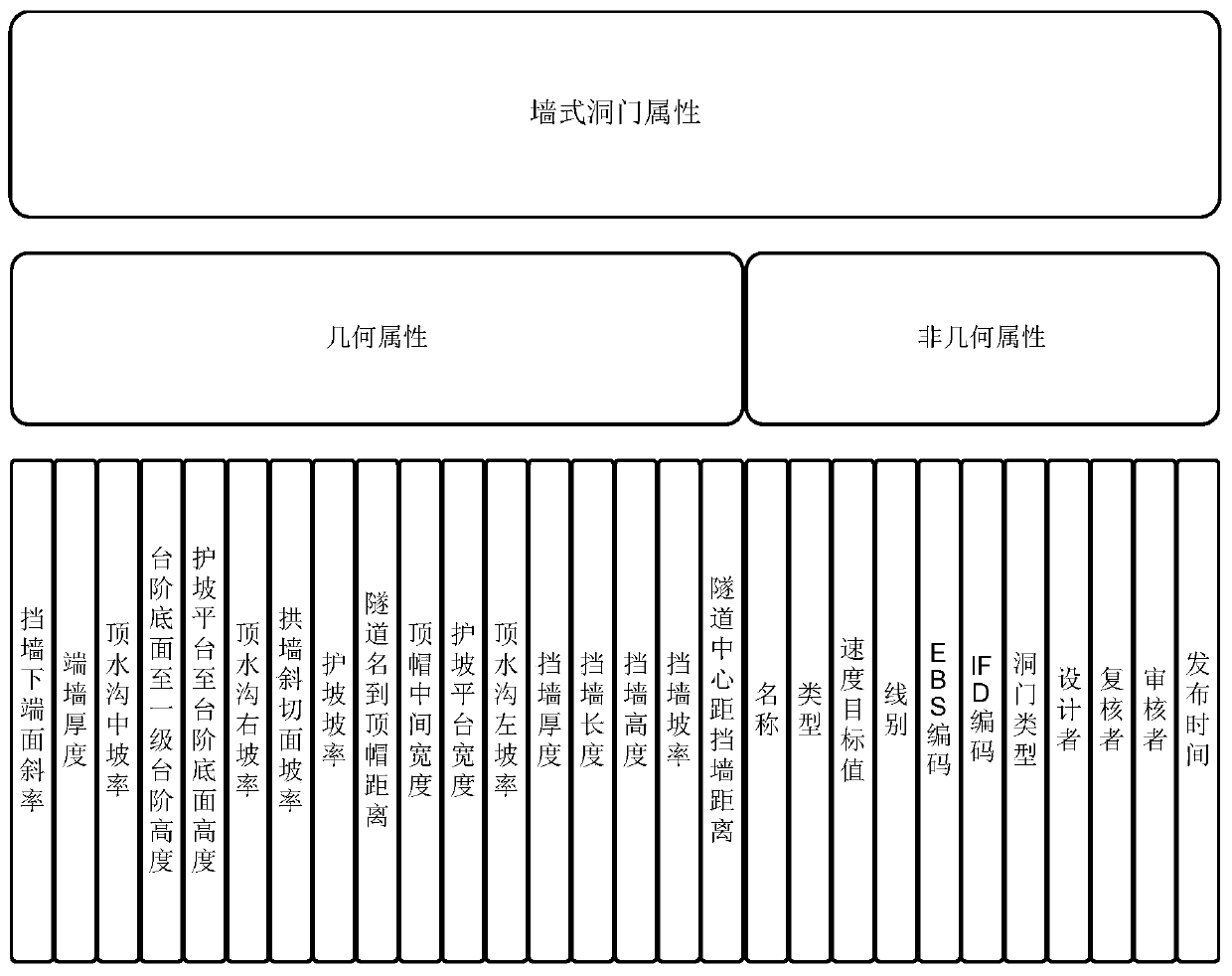

Railway engineering component parameterization method based on Ilogic

PendingCN110069818AImprove readabilityImprove efficiencyGeometric CADData processing applicationsReadabilityModel parameters

The invention belongs to the technical field of BIM (Building Information Modeling), and discloses a railway engineering component parameterization method based on Ilogic, which comprises the following steps of: (1) decomposing a railway engineering component into a plurality of basic components according to a railway BIM union standard, and dividing the attributes of the basic components into geometric attributes and non-geometric attributes by combining an IFC attribute; (2) establishing an IFC template of the basic component according to railway IFC classification, utilizing an ilogic technology component to contain a form of an IFC attribute, and pre-writing an attribute value; (3) establishing a parameterized BIM model, setting attribute information and non-geometric information, andparameterizing railway engineering components; (4) the form information is associated with model parameters, different BIM models are obtained by setting different geometric parameter values and non-geometric attributes, and a form driving model is achieved; (5) exporting the model with the IFC attribute information as an IFC file; according to the method, on the basis of parameterization of an ilogistic form, parameters of parts are organically integrated on one form, parameterization of components is achieved to the maximum extent, and the readability of the components and the efficiency ofcomponent design are greatly improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

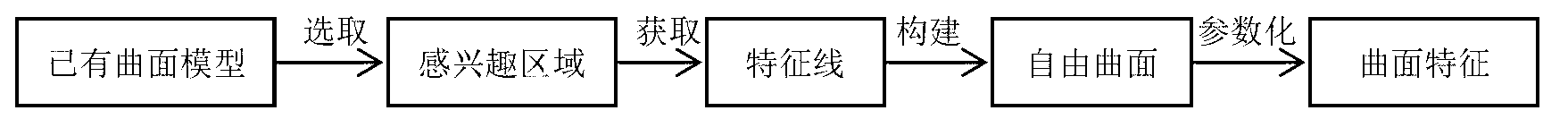

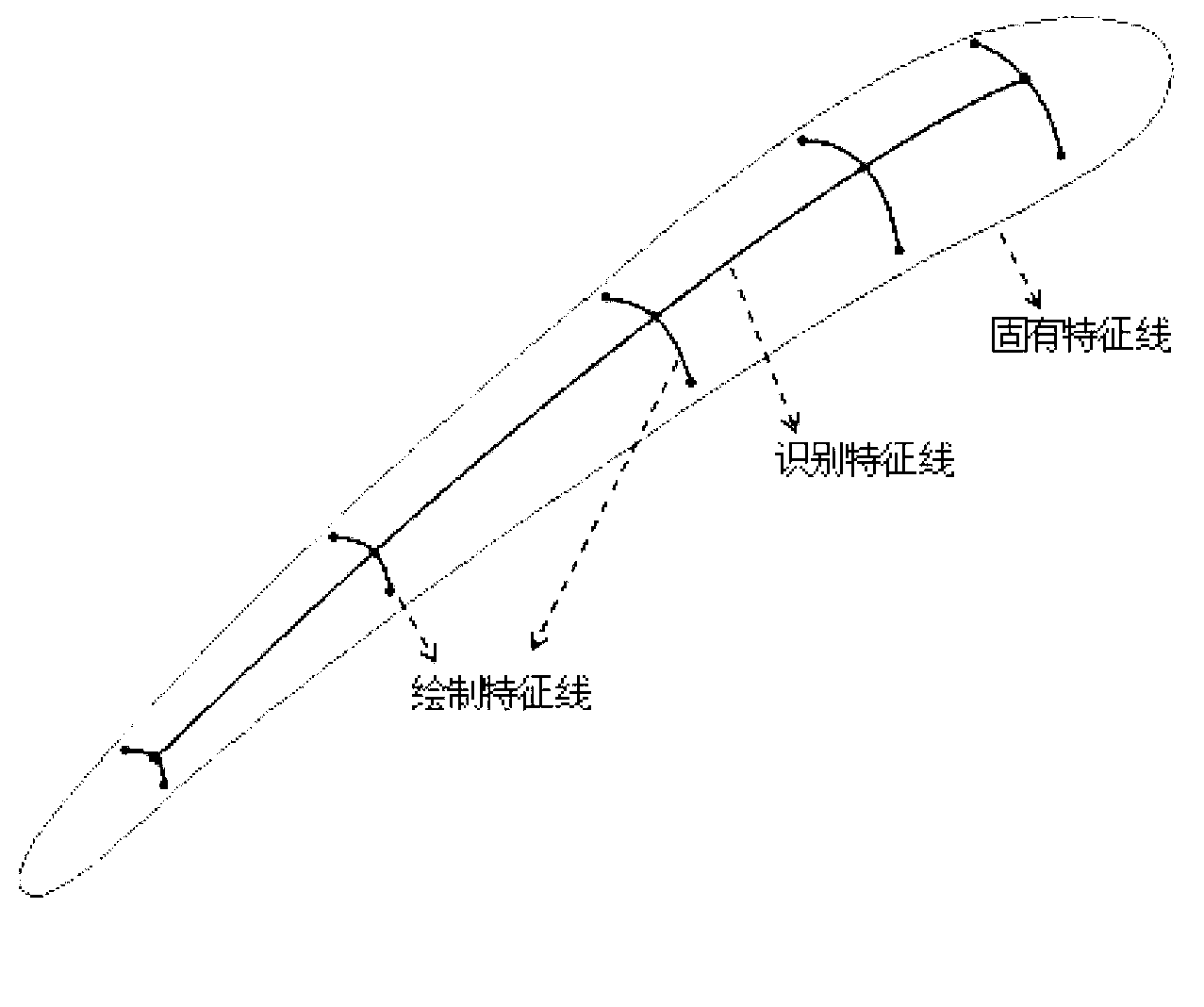

Method for defining curve surface features by user based on existing models

InactiveCN103310050ARealize parameterizationEnable design reuseSpecial data processing applicationsUser needsComputer Aided Design

The invention discloses a method for defining curve surface features by a user based on existing models, the geometric information of the existing models is utilized, a local curve surface area interested by the user is selected, and a new curve surface feature is automatically generated. The method comprises the steps as follows: in view of a large amount of existing curve surface models, selecting the local curve surface area with engineering semantics according to the user demand at first; then reconstructing a curve surface in the shape of the local area by obtaining related information based on feature lines in the local area and selecting a proper curve surface generation mode; and finally parameterizing the generated new curve surface. The method is mainly characterized in that the user is supported to automatically select the local area with the engineering semantics from the existing models, the characterization is achieved, and the redesign from a bottom layer each time is avoided; and the method is applied to the CAD (computer-aided design) model design and can promote the design reuse and the design transformation of a product, shorten the development cycle of the product and improve the design efficiency.

Owner:HOHAI UNIV CHANGZHOU

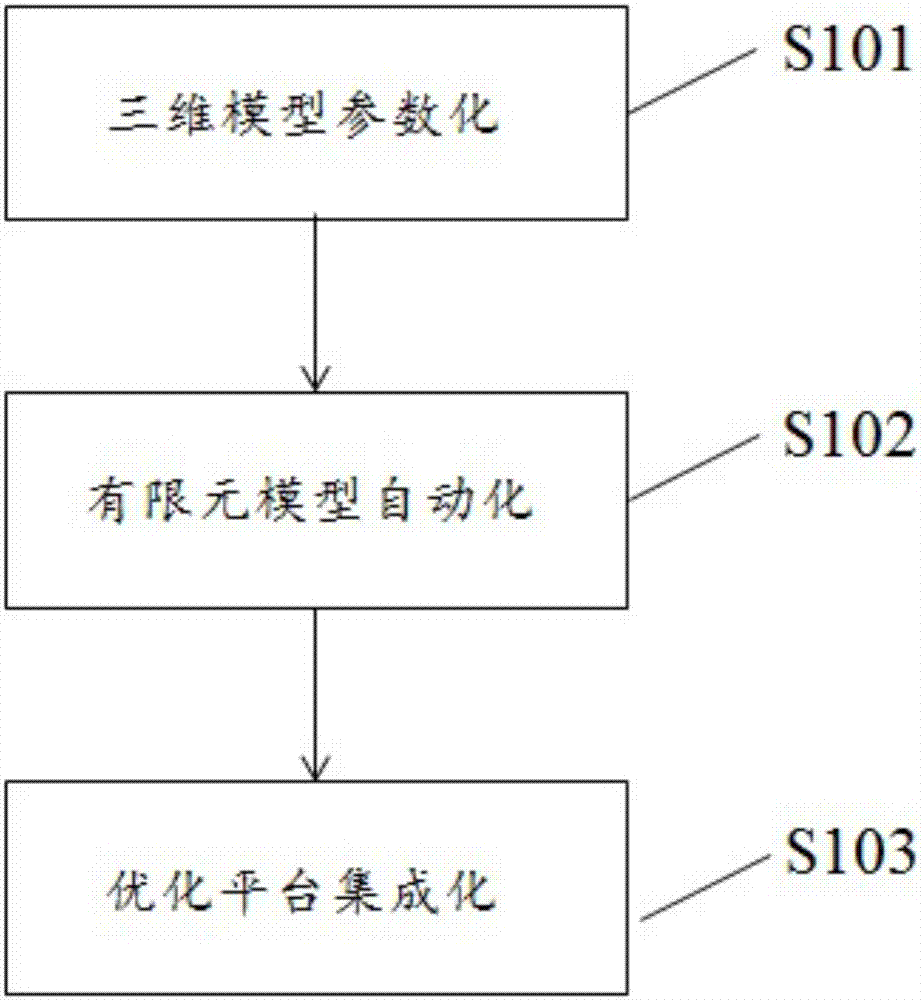

Product structure dimension optimization method

InactiveCN106919763AOptimize parameterizationRealize parameterizationGeometric CADDesign optimisation/simulationData connectionElement model

The invention relates to the technical field of computer simulation, and especially relates to a product structure dimension optimization method. The method comprises the steps of three-dimensional model parameterization, finite element model automation and optimization platform integration. According to the method, based on CAD, CAE and optimization software, related data connection is established, and parameterization, automation and integration of product dimension optimization are achieved. Optimization processes are integrated, automatic modeling, analysis and optimization are achieved, non-linear problems are considered, optimization quality and working efficiency are improved, and the research and development cycle is shortened.

Owner:上海波客实业有限公司

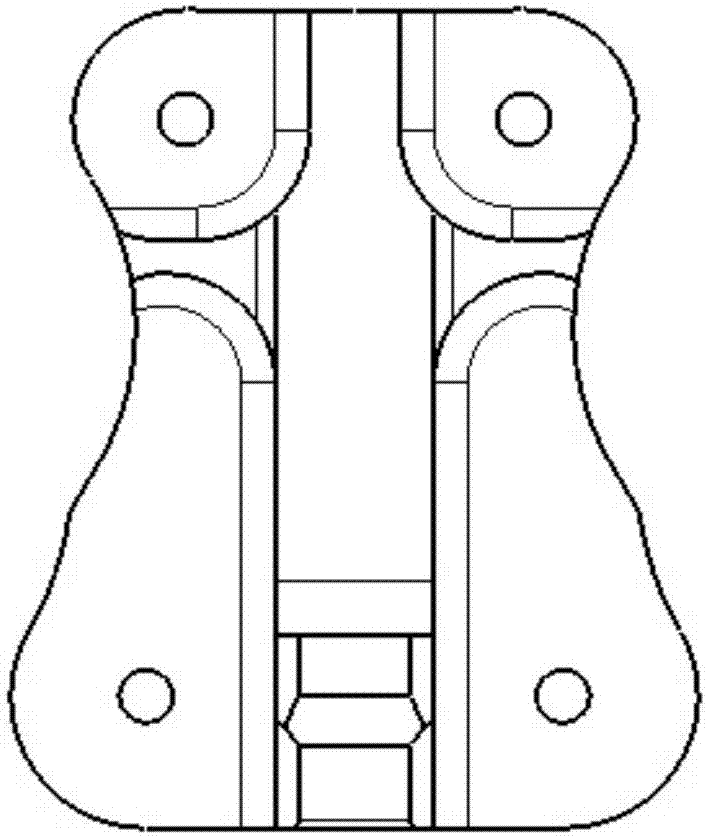

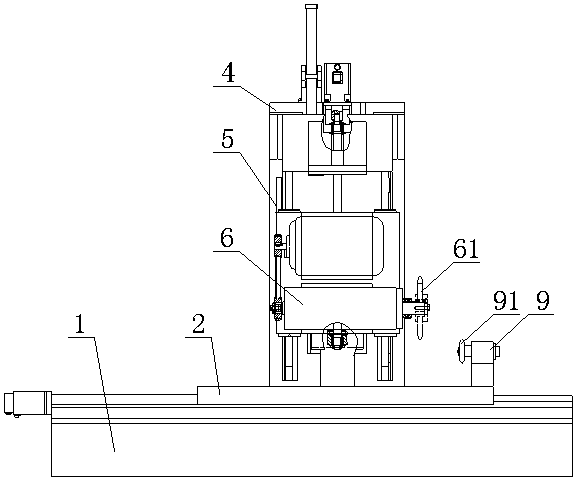

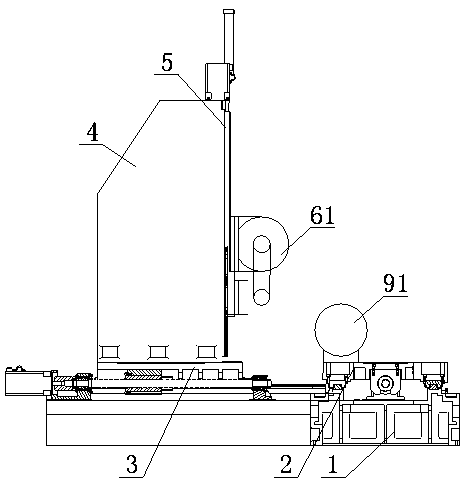

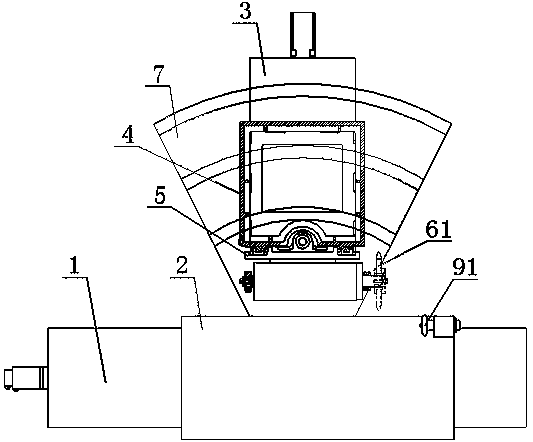

Multifunctional numerical control gear grinding machine tool

ActiveCN103464832ARealize parameterizationShorten adjustment timePrecision positioning equipmentFeeding apparatusGear grindingEngineering

The invention relates to a multifunctional numerical control gear grinding machine tool, which comprise a machine tool body and a numerical control system for controlling devices to work, wherein the machine tool body is provided with a longitudinal sliding table and a transverse sliding table; a vertical column is arranged on the transverse sliding table; a vertical sliding table is arranged on the vertical column; a grinding head assembly is arranged on the vertical sliding table; a longitudinal sliding mechanism is arranged between the longitudinal sliding table and the machine tool body; a transverse sliding mechanism is arranged between the transverse sliding table and the machine tool body; a vertical sliding mechanism is arranged between the vertical sliding table and the vertical column; and the grinding head assembly comprises a grinding wheel grinding head and a motor for driving the grinding wheel grinding head to rotate. According to the multifunctional numerical control gear grinding machine tool, full numerical control is adopted, a computer numerical control (CNC) system is used for controlling the work of each working component, so that integration of auxiliary technologies such as profile grinding, online trimming, an online real-time measurement technology and an automatic machining allowance allocation technology is realized, and the adjusting time of profile grinding can be saved.

Owner:常州紫云英机电工程有限公司

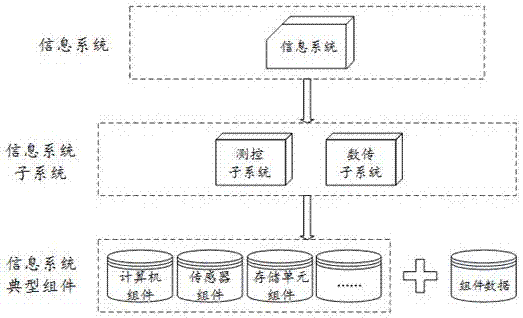

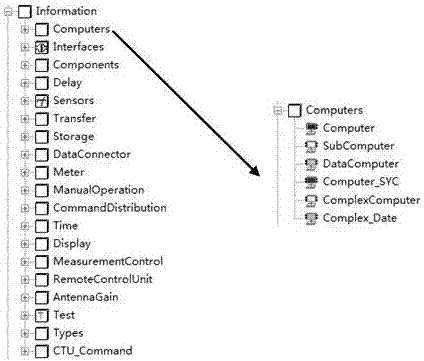

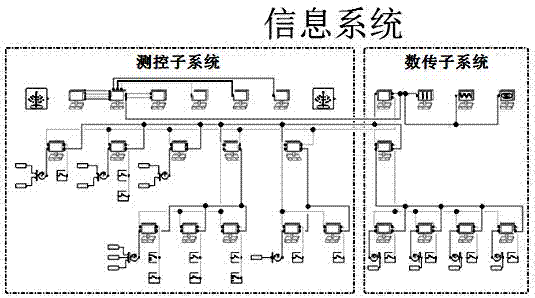

Spacecraft information system modeling simulation method based on Modelica language

ActiveCN107341294AQuick buildReduce workloadGeometric CADDesign optimisation/simulationExtensibilityData stream

The invention discloses a spacecraft information system modeling simulation method based on a Modelica language. According to the method, an information system modeling simulation theory and a Modelica technological system are combined to form an object-oriented statement-type modeling method used for constructing a non-causality information system model base; and meanwhile a modeling simulation system is developed and used for realizing construction, management and simulation analysis of a component model and an information system model. Through the method, it is not needed to decouple an information system or stipulate a component input and output order and an equation solving order, the simulation system can determine the equation solving order according to an equation system data stream environment only in the solving process, therefore, the difficulty and complexity of information system modeling are greatly lowered, modeling workload is lowered, errors brought by manually designating the solving order are avoided, the reusability, expandability, flexibility and knowledge accumulation capability of the models are remarkably improved, and modularization, parameterization and visualization are realized under the support of the modeling simulation system.

Owner:苏州同元软控信息技术有限公司

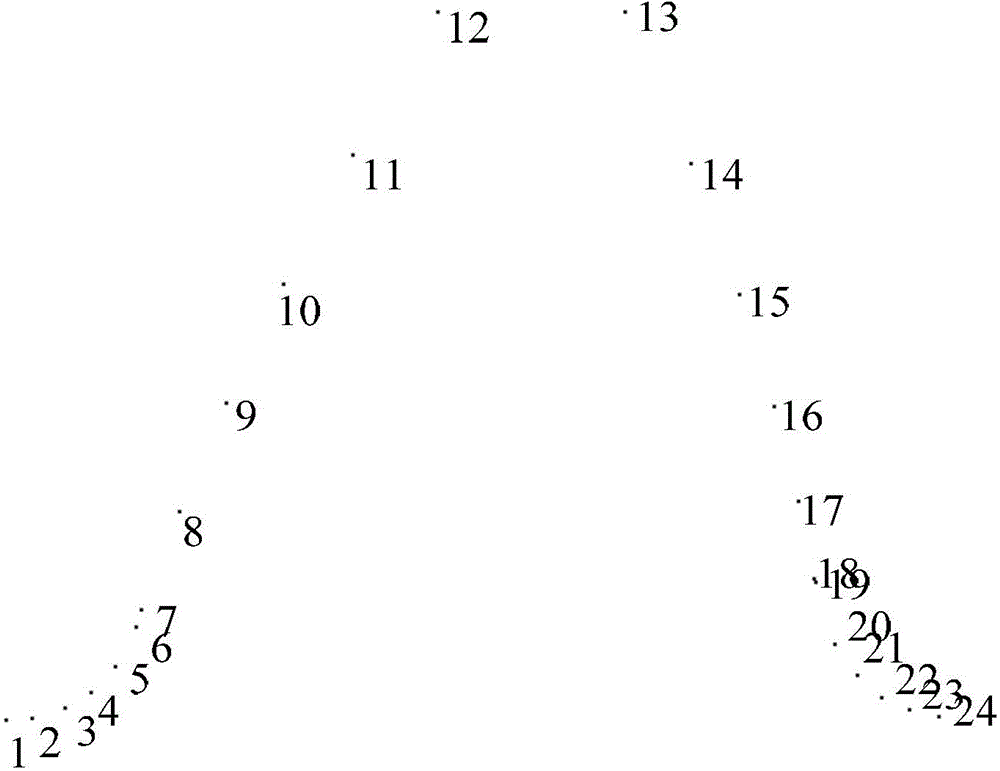

Modeling method of asymmetric spur gear pair

ActiveCN104318017AEnables dynamic mesh analysisAvoid crossingPortable liftingSpecial data processing applicationsModel methodElement model

The invention relates to a modeling method of an asymmetric spur gear pair. The modeling method includes firstly calculating coordinates of equant key points on a gear profile by a gear profile of an asymmetric spur gear, creating gear profile key points by ANSYS software, generating a gear profile sample curve of the key points, setting up a single-gear end face, an integral-gear end face, a solid asymmetric spur gear model and an asymmetric spur gear transmission pair model, finally dividing finite element grids and setting dynamic constraints and load to obtain an asymmetric spur gear transmission pair finite element model. The integral modeling process realizes parameterization, and finite element modeling quality of a gear transmission system as well as analysis efficiency is greatly improved.

Owner:JIANGSU UNIV OF TECH

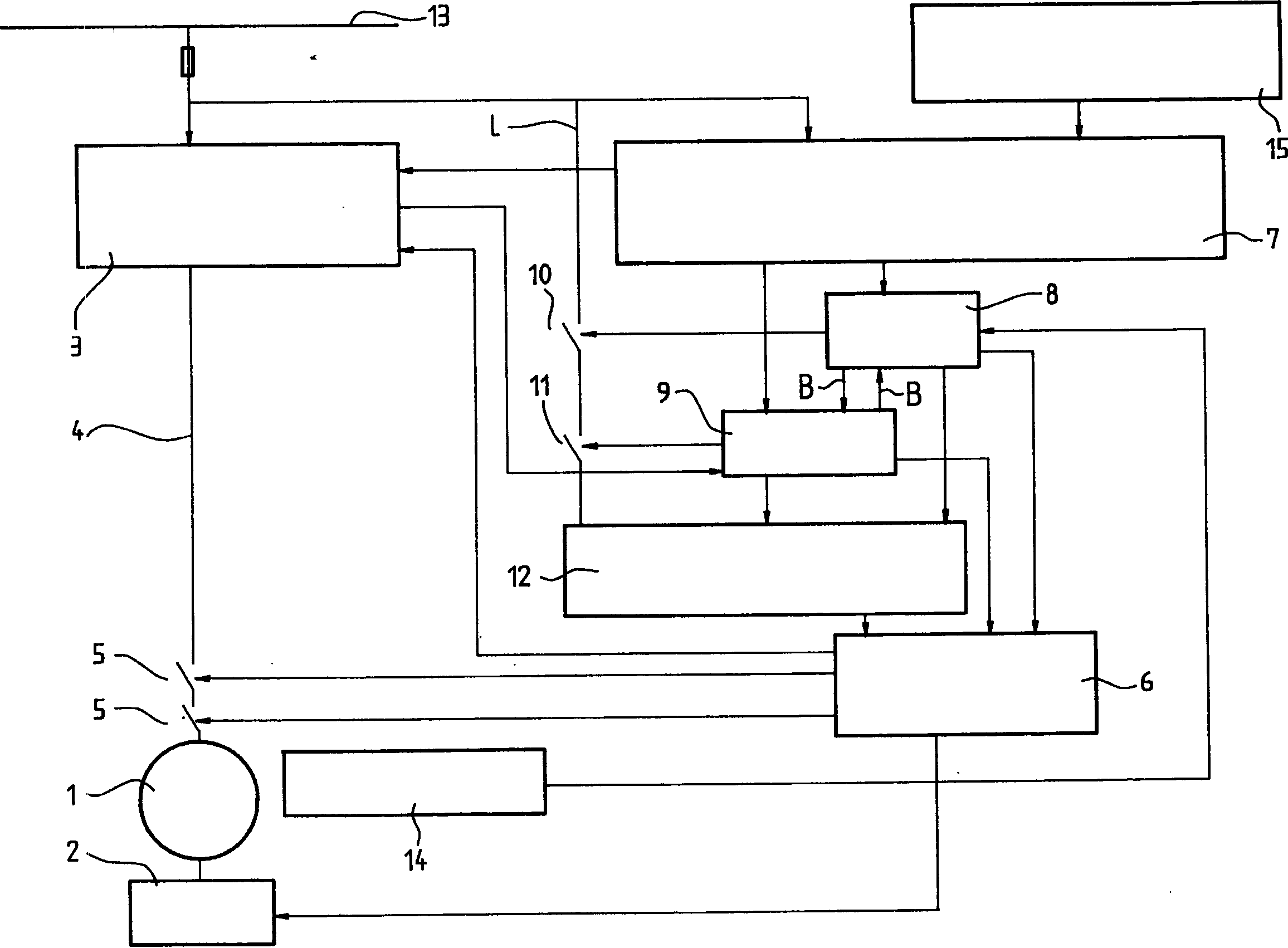

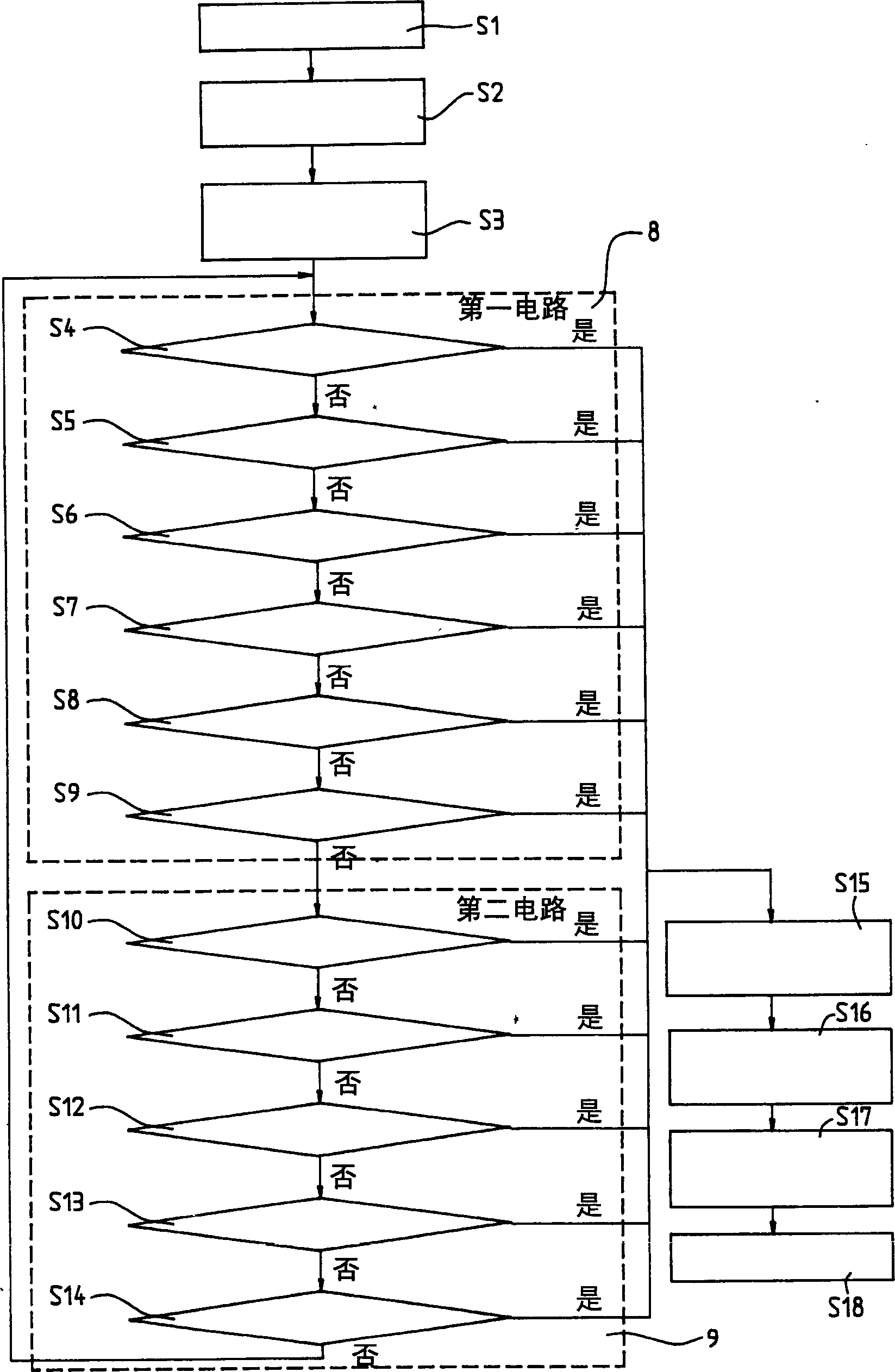

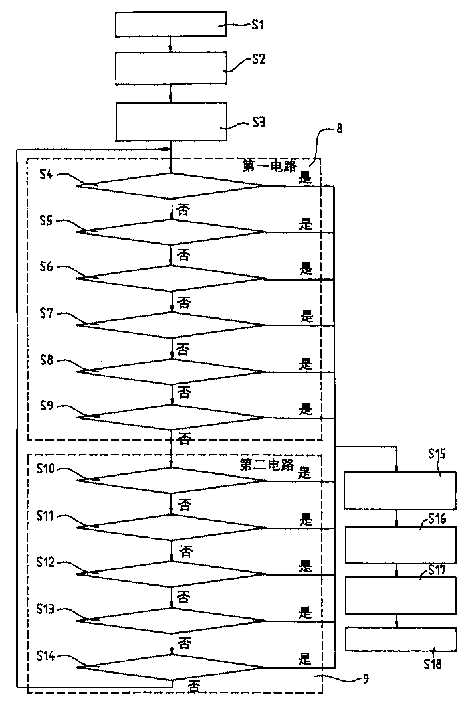

Method for stopping personnel transport equipment operation

The invention relates to a method for stopping conveying equipment for persons, wherein on response of a safety element a braking process determined by a frequency converter (3) co-operating with a drive motor (1) is initiated, by means of which the conveying equipment for persons is brought to a standstill, wherein the braking proces s is monitored by a safety circuit (8, 9) which comprises at least a first channel (8) and a second channel (9) The operational safety of the braking system is thereby increased.

Owner:INVENTIO AG

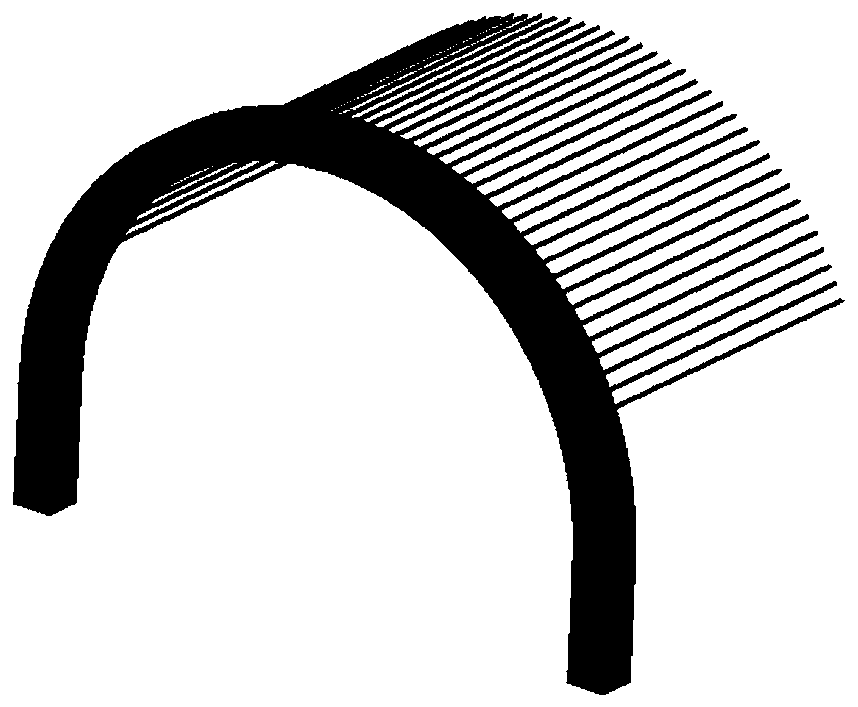

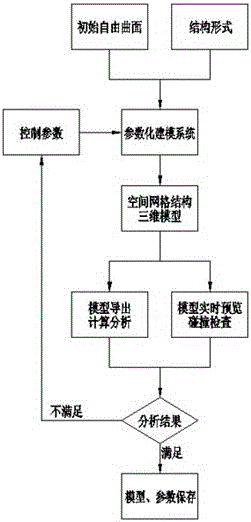

Free-form surface-based parametric modeling method of space grid structure

InactiveCN106599463ARealize parameterizationImprove modeling efficiencyGeometric CADSpecial data processing applicationsNODALFree form

The invention discloses a free-form surface-based parametric modeling method of a space grid structure. The technology specifically comprises the following steps of (1) building an initial free-form surface; (2) determining a space grid structure form and setting model control parameters of the space grid structure for controlling the number of structure nodes and a thickness change of the structure; (3) carrying out grid partition and grid uniformity optimization on the free-form surface according to the control parameters to obtain corresponding space nodes; and (4) carrying out logic grouping arrangement on the space nodes through a default algorithm and automatically connecting the nodes according to a certain rule to form a three-dimensional model of the space grid structure. According to the technology, a parameter-driven model change can be achieved, the parameters and the model are stored together, a new model can be built through simply changing model parameter values, parameterization of the model is achieved and the modeling efficiency and accuracy are greatly improved.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

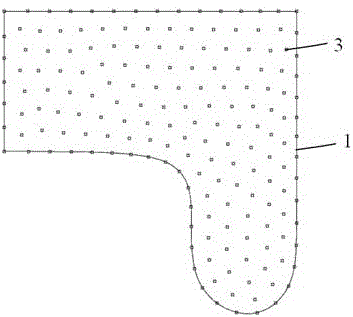

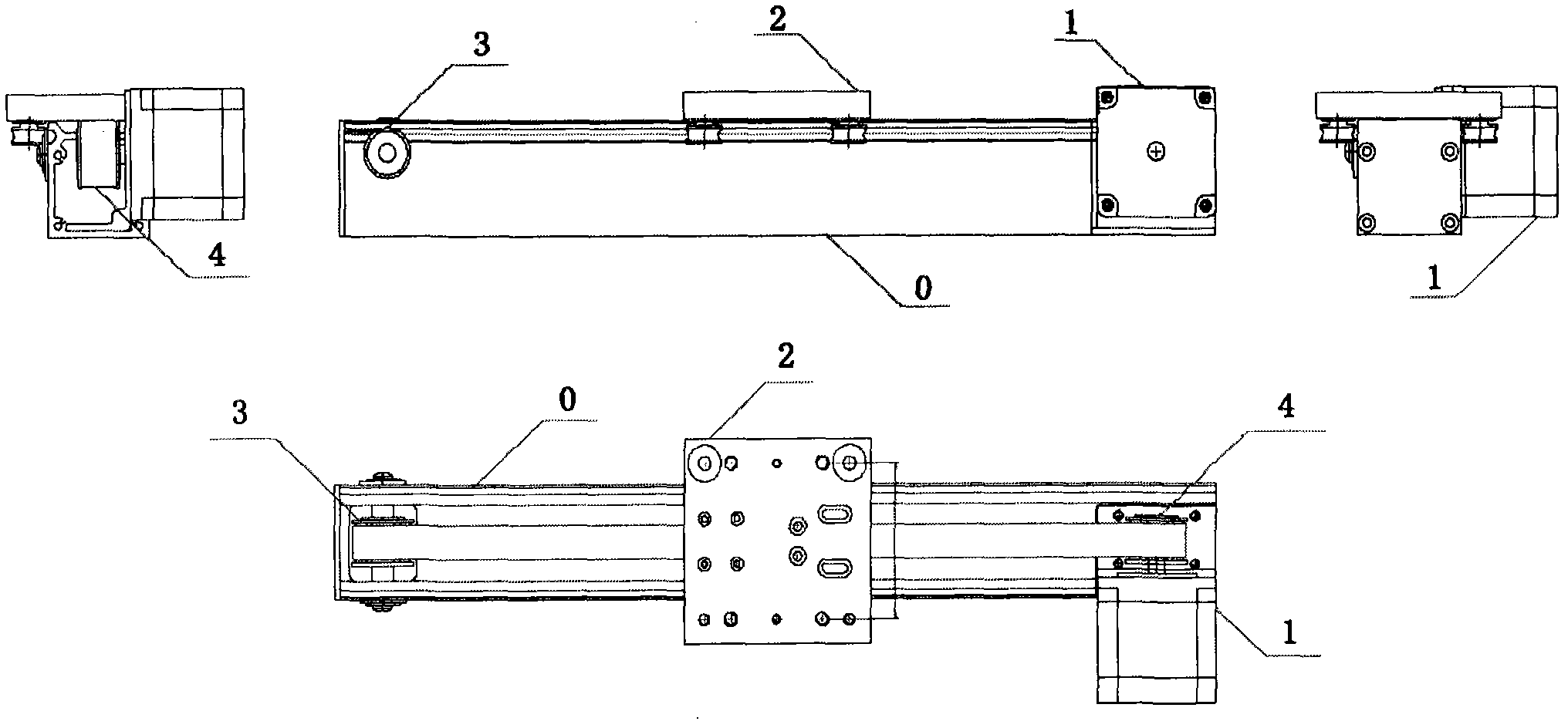

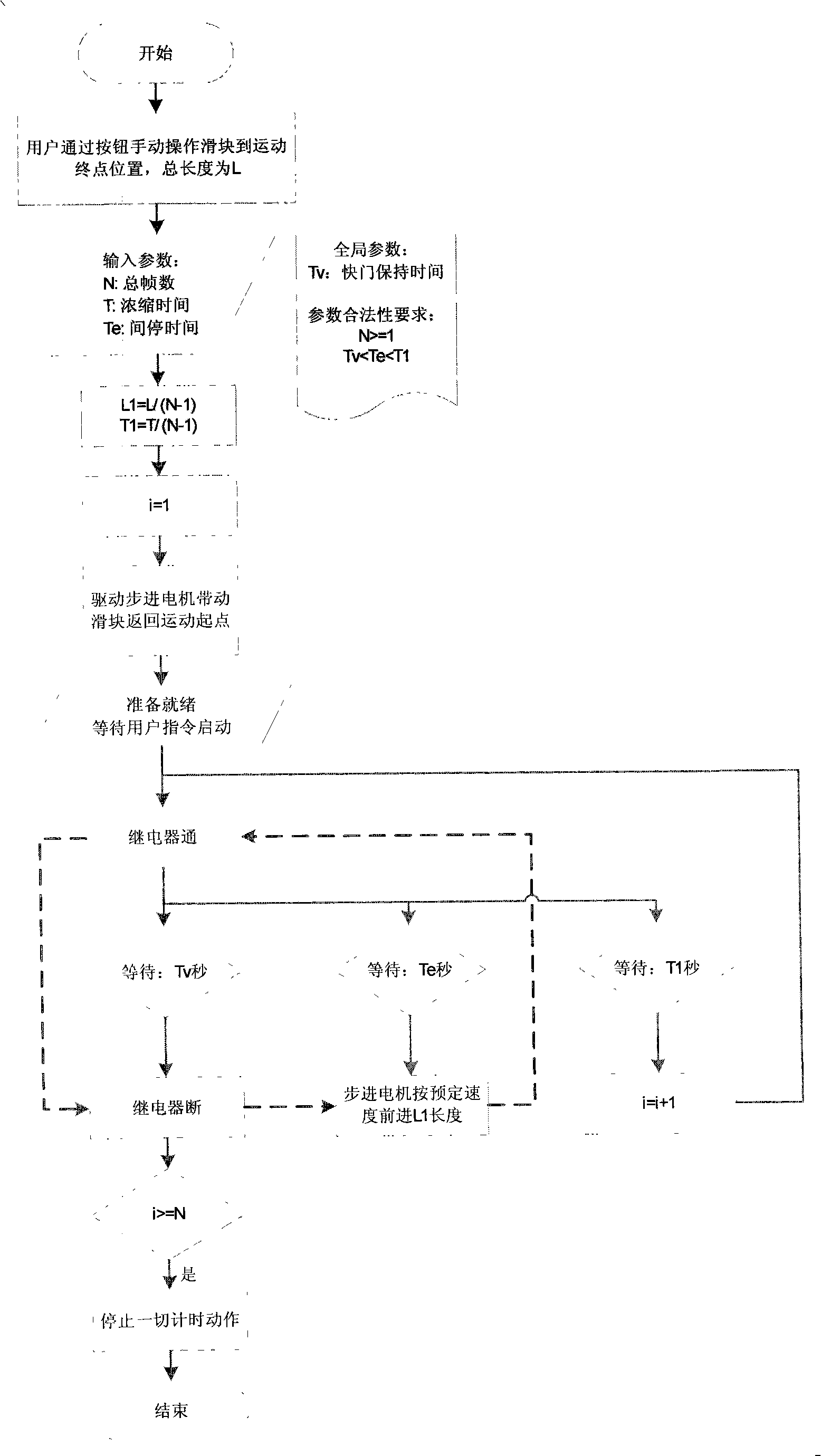

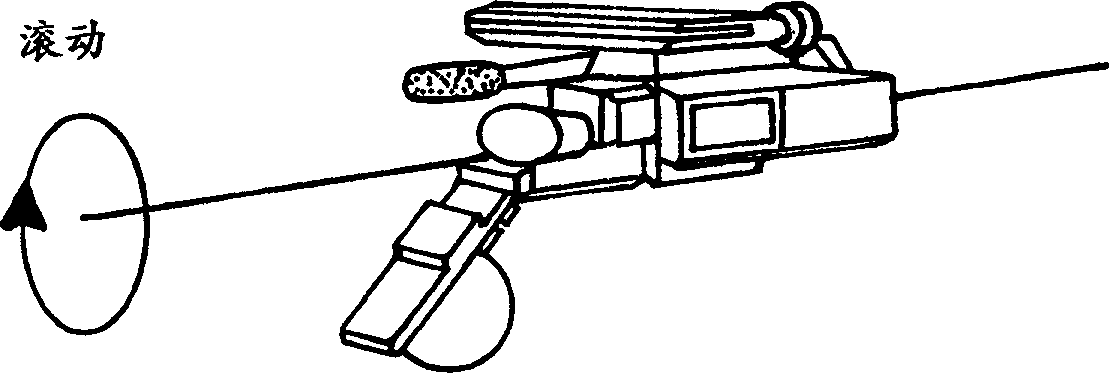

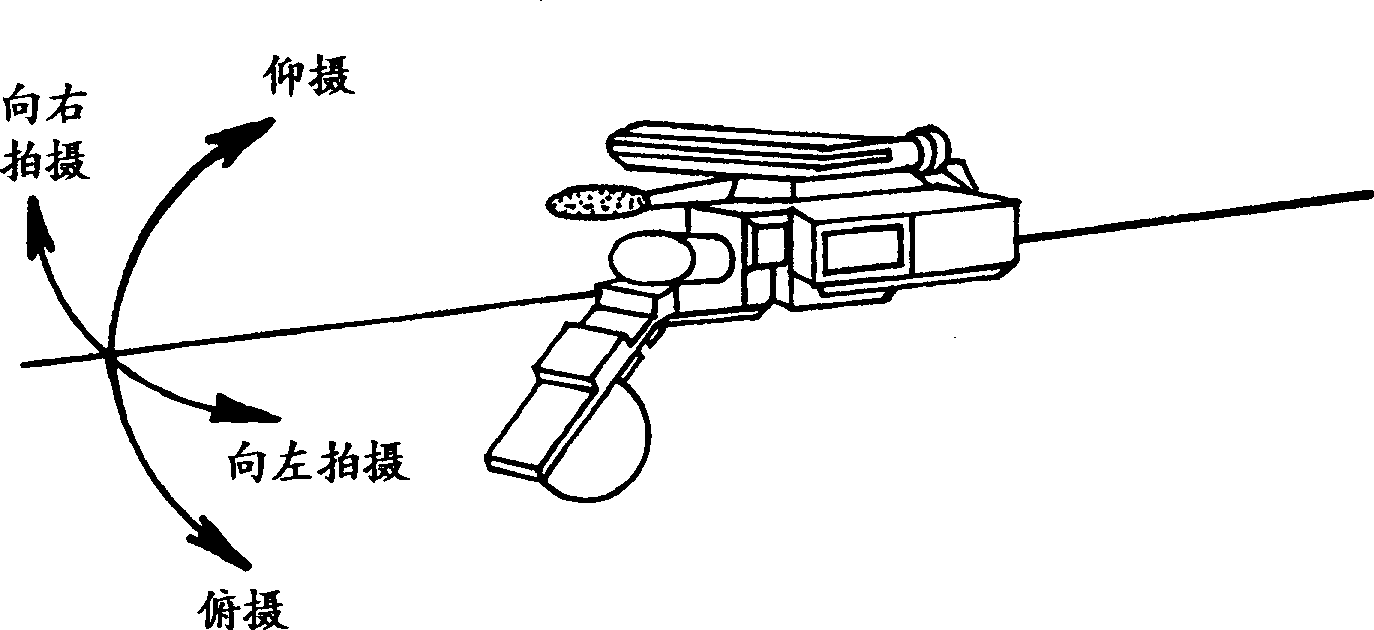

One-dimensional motion system of camera

ActiveCN102611841AFully automatedRealize parameterizationTelevision system detailsColor television detailsMicrocontrollerEngineering

The invention provides a one-dimensional motion system of a camera, which comprises a stepper motor and a single-chip microcomputer; the stepper motor drives a slider to move on a rail, and the camera is fixedly arranged on the slider; and the single-chip microcomputer controls the stepper motor and the shutter of the camera through a relay. The single-chip microcomputer comprises four control modes, i.e. a single-period time-lapse shooting mode, a multi-period time-lapse shooting mode, a single-period smooth motion mode and a multi-section smooth motion mode. According to the one-dimensional motion system of the camera, the single-chip microcomputer is adopted to control the motion of the camera and the on or the off of the shutter, so that the automatic and parameterized one-dimensional motion of the camera is simply and reliably realized, a user can realize the mobile shooting of the camera in a space or on a line segment by setting a group of parameters, the shooting requirements on moving shots in general movie shooting as well as time-lapse shooting, frame-by-frame animation and the like are met, and more innovation space is provided for a photographer.

Owner:王笑恒

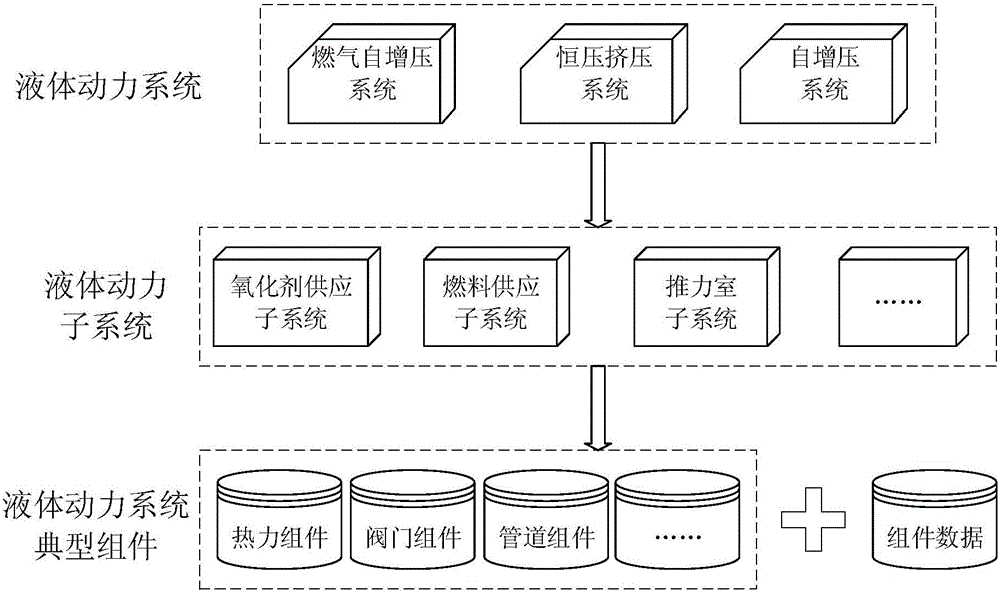

Model-based dynamic analysis method for extruded two-component liquid power system

ActiveCN105975692AQuick buildReduce difficultySpecial data processing applicationsModelicaReusability

The invention discloses a model-based dynamic analysis method for an extruded two-component liquid power system. An object-oriented declarative liquid power system modeling method is formed by combining a liquid power system modeling simulation theory with a Modelica technical system and used for guiding a modeling process of a non-causal model library of the liquid power system. For a complex system such as the liquid power system, the system does not need to be decoupled, and component input / output and equation solving sequences do not need to be defined, so that the difficulty and complexity of system modeling are greatly lowered, the workload is reduced, an error caused by manually specifying the solving sequence is avoided, and the reusability, expandability, flexibility and knowledge accumulation capability of models are remarkably improved.

Owner:XIAN AEROSPACE PROPULSION INST

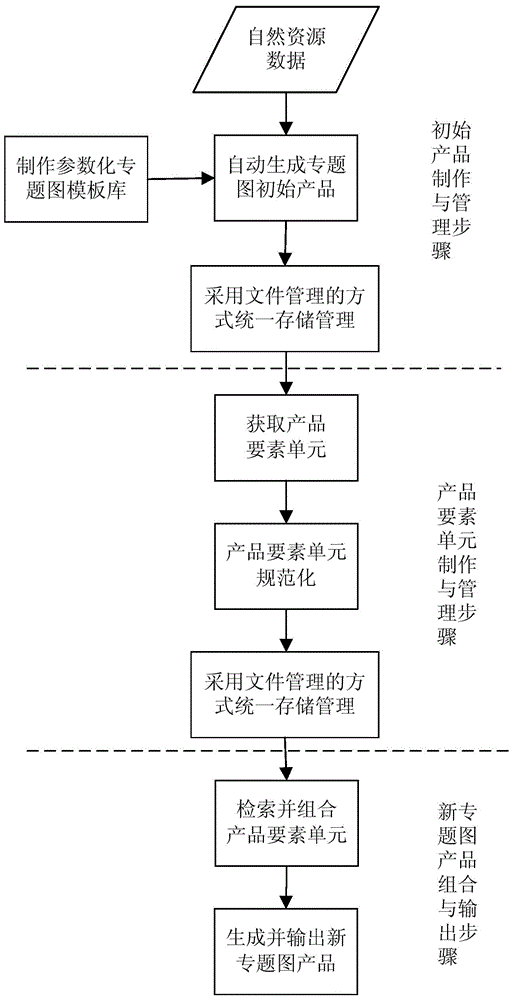

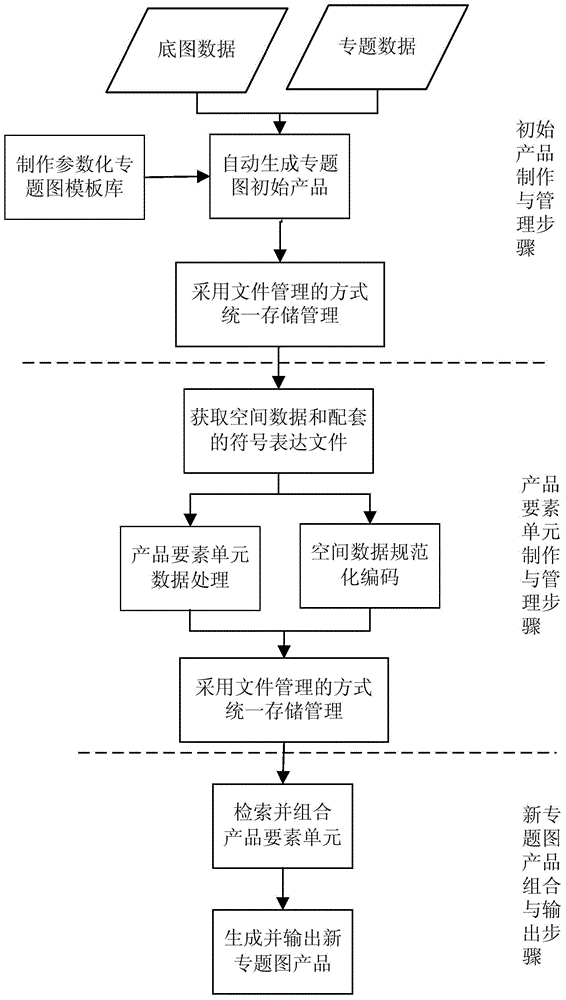

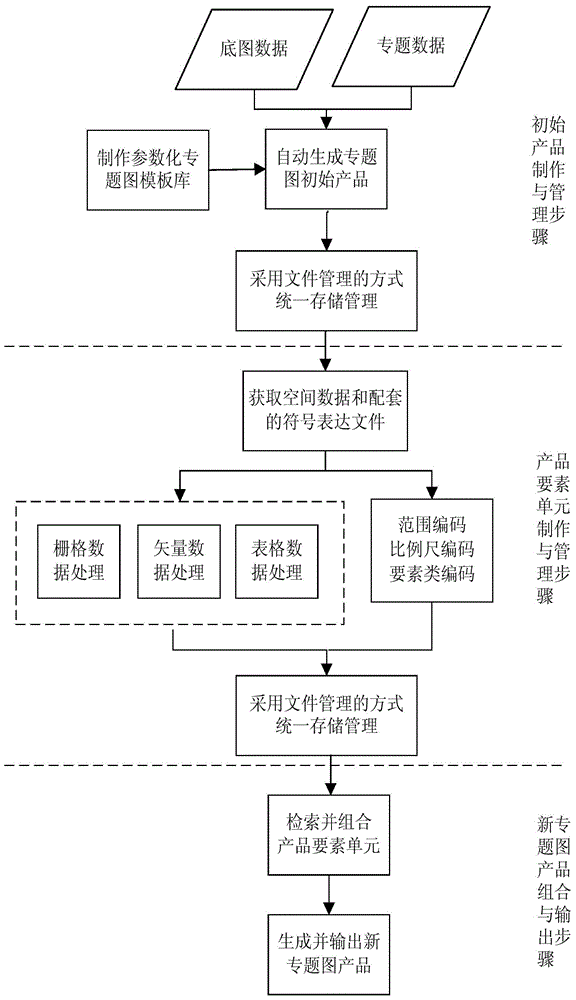

Natural resource element level product manufacturing method and system

InactiveCN104951567AImprove the preparation effectHigh precisionFile access structuresGeographical information databasesNatural resourceThematic map

The invention relates to a natural resource element level product manufacturing method. The method comprises an original product manufacture and management step, a product element unit manufacture and management step and a new thematic map product combination and output step. Firstly, a parameterized thematic map template library is manufactured, collected natural resource data are loaded to generate thematic map original products automatically, and the generated thematic map original products are stored and managed unifiedly; product element units are obtained, subjected to normalized data processing and normalized encoding and unifiedly stored and managed in a file management manner; association retrieval of target product names of the unifiedly stored and managed product element units is established on the basis of an engine retrieval technique, and the required product element units generate and output new thematic map products after combined. With the adoption of the method, automation and parameterization of GIS (geographic information system) thematic map product manufacture are realized, and the manufacture effect, precision and efficiency of the natural resource element level products are greatly improved.

Owner:国家信息中心

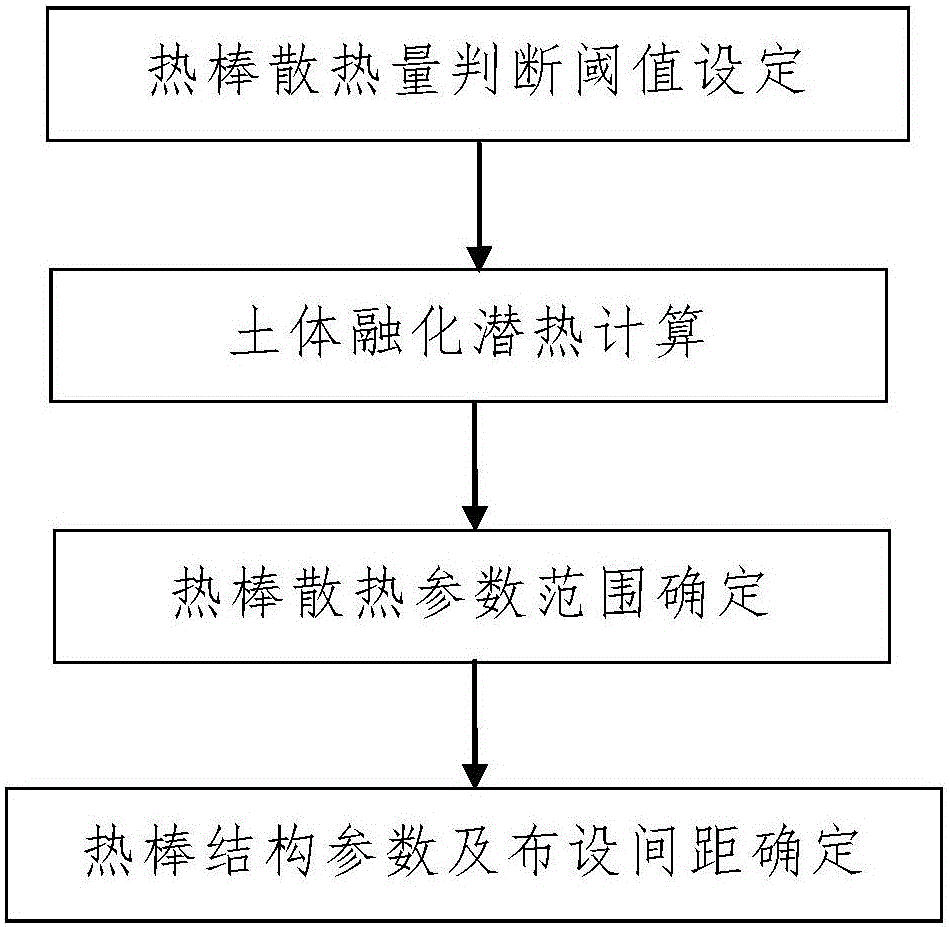

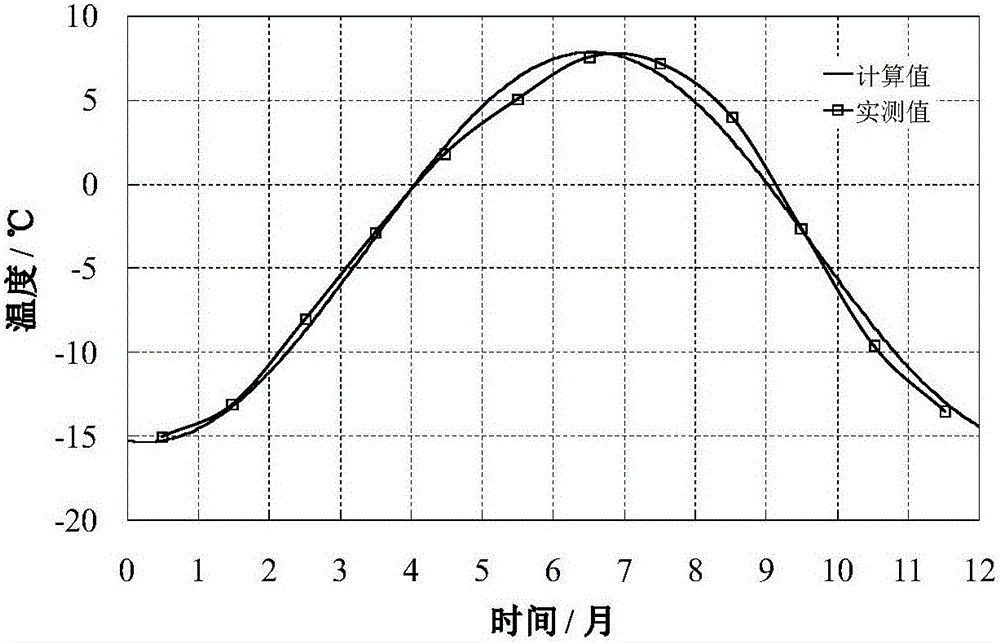

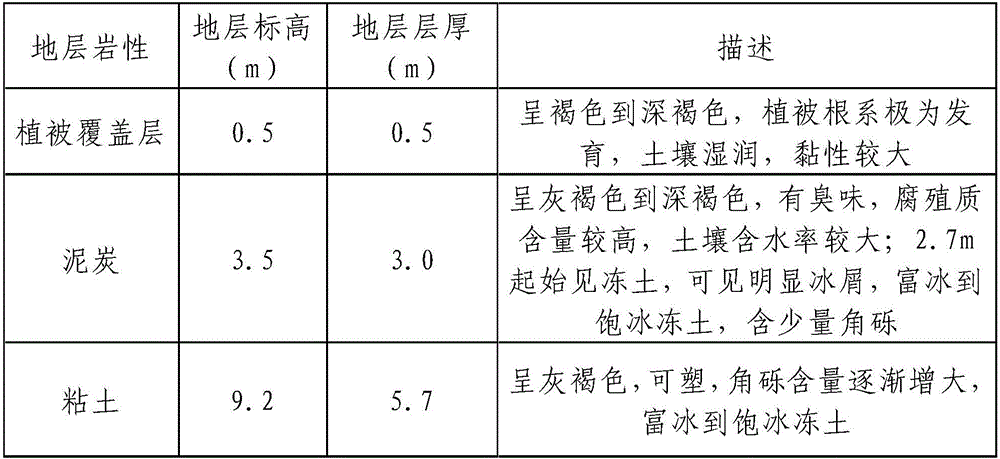

Permafrost region thermal pipe subgrade parameter designing method based on energy balance theory

ActiveCN106120506AThe method steps are simpleReasonable designRoadwaysQuantum dissipationLatent heat

The invention discloses a permafrost region thermal pipe subgrade parameter designing method based on the energy balance theory. The method comprises the steps that firstly, a judging threshold value of the heat dissipation amount of thermal pipes is set; secondly, soil melting latent heat is worked out, specifically, the soil melting latent heat of a constructed permafrost region subgrade is worked out; thirdly, the heat dissipation parameter range of the thermal pipes is determined, specifically, the heat dissipation parameter range of the thermal pipes is determined according to combination of the set judging threshold value of the heat dissipation amount of the thermal pipes with the soil melting latent heat; and fourthly, the thermal pipe structural parameter and the arrangement interval are determined, specifically, the thermal pipes are selected according to the determined thermal pipe heat dissipation parameter range, and by combining the structural parameter of the selected thermal pipes, the thermal pipe arrangement interval in the constructed permafrost region subgrade is determined. The method is simple in step, reasonable in design, convenient to implement and good in application effect, and according to the predetermined soil melting latent heat, the thermal pipe structural parameter and the arrangement interval of the permafrost region thermal pipe subgrade are determined based on the energy balance theory.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

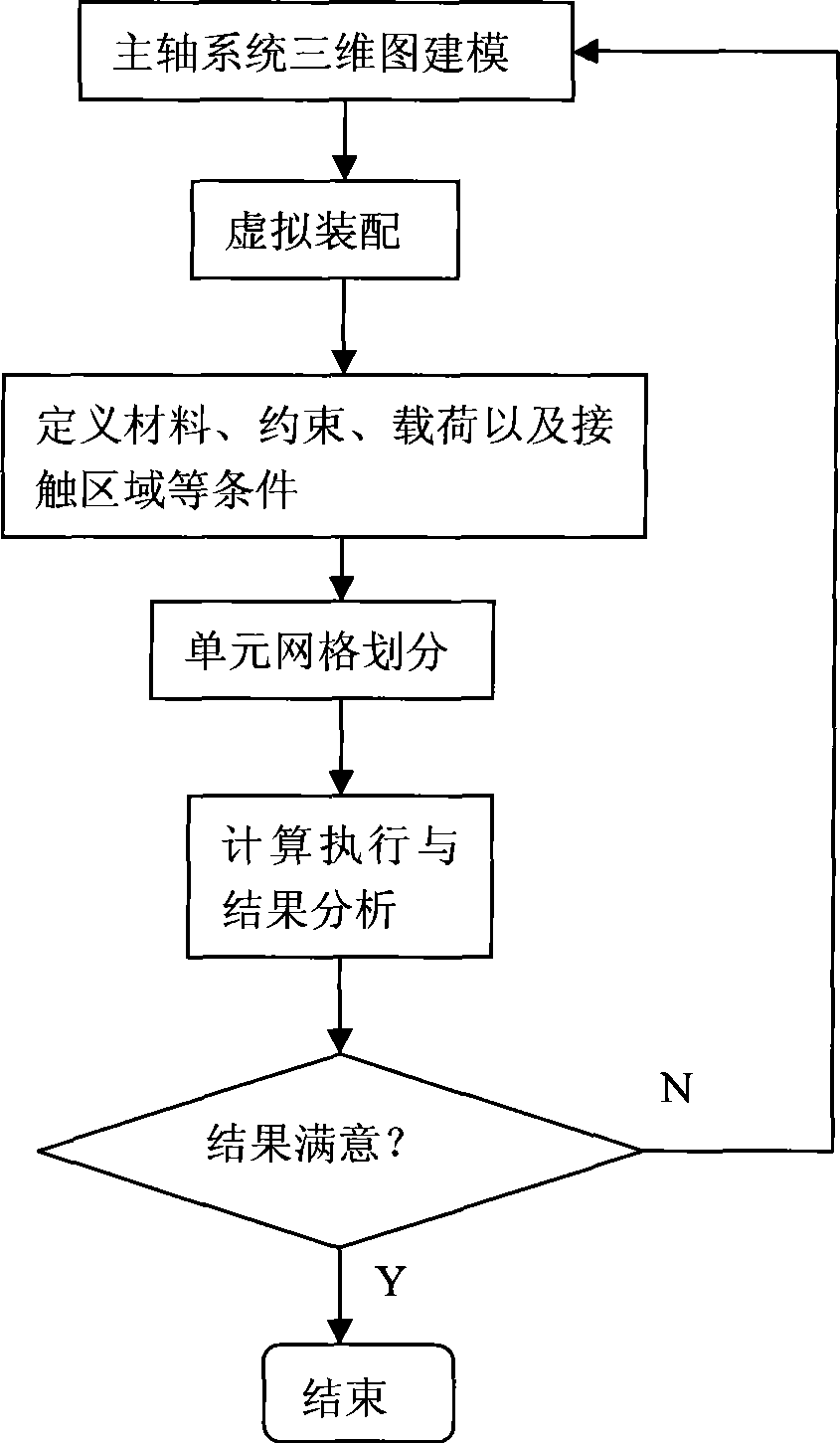

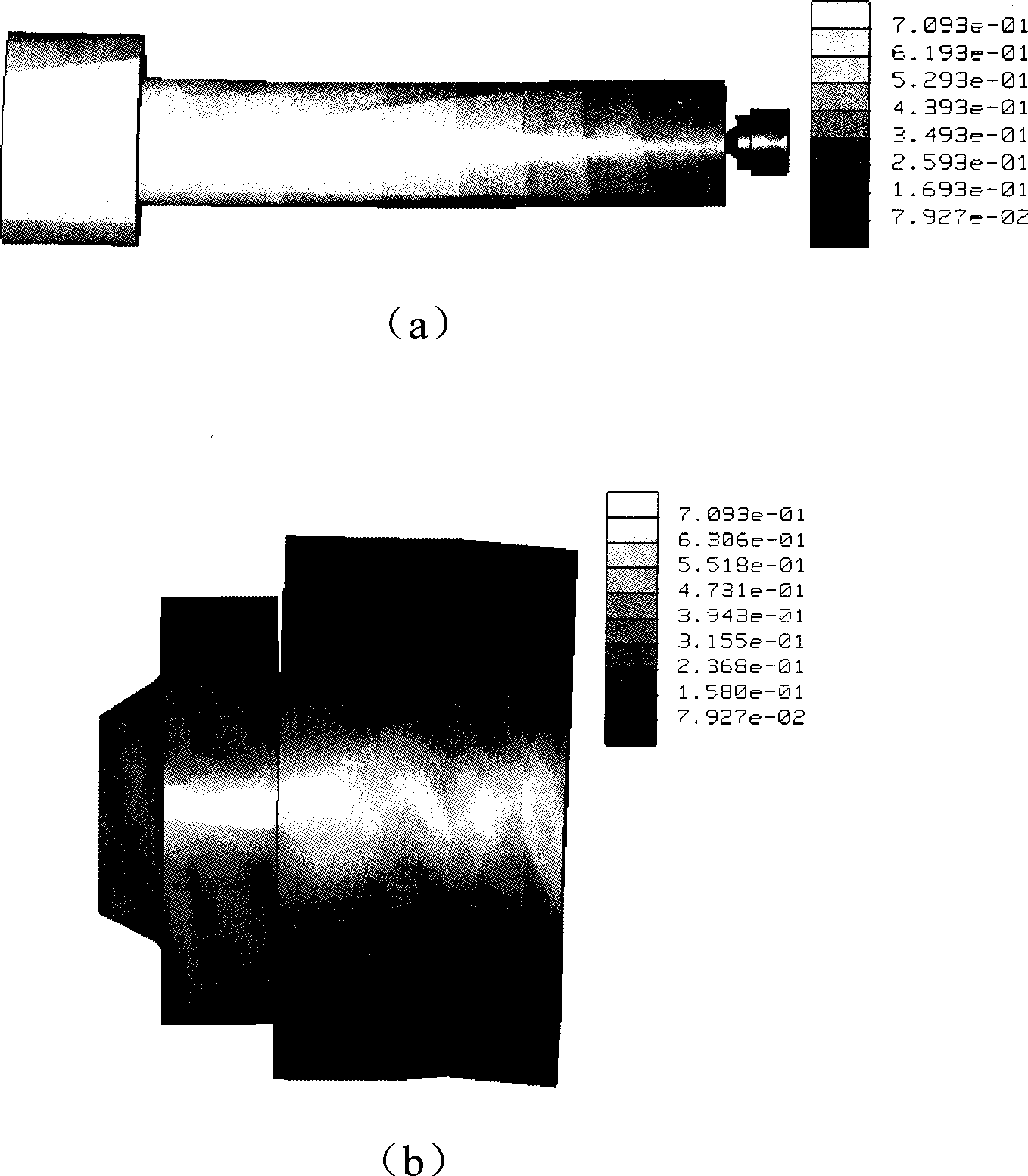

Non-support grinding and high stiffness principal axis system simulation and analysis method

InactiveCN101393582AOptimized designAchieve seamless connectionSpecial data processing applicationsTechnical supportAnalysis method

The invention relates to an emulation analytic method for a supportless grinding high rigidity main shaft system. The method comprises the following steps: based on three-dimension design software Pro / E, a three-dimension geometrical model is built to finish an assembly and form a digital prototype machine; seamless connection is realized by using submodule Pro / MECHANICA analyzing software of Pro / E; and in the submodule Pro / MECHANICA, a region is defined to restrict, load and contact, and the results of the stress and transfiguration of various relative parts are output after the calculation is performed. Considering various factors affecting the rigidity of the main shaft system, such as influences on contacting length between a core clamper and the center hole of a workpiece, the conicity of the center hole, the diameter of a bolt, arrangement mode, pretightening force, the conicity of a taper sleeve and magnitude of interference of the taper sleeve, the emulation analytic method provides a strong technical support for the design and manufacture of the supportless grinding high rigidity main shaft system with high performance.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Ceramic matrix composite bolt prefabricated body-structure integrated design method

ActiveCN110334461AImprove forecast accuracyHigh precisionGeometric CADDesign optimisation/simulationStress conditionsIntegrated design

A ceramic matrix composite bolt fabricated body-structure integrated design method comprises the following steps: modeling a prefabricated body; carrying out structure modeling; deformation and failure calculation. According to the actual microstructure of the ceramic matrix composite, different small composites in the bolt are built, and macroscopic failure of the structure caused by microscopicfailure in the small composites can be achieved. The thread built by the method can reflect a thread tooth failure form, and the influence of complex stress conditions on the thread on a screw fracture failure form is also considered, so that the prediction accuracy of the strength of the CMCs bolt is improved. According to the actual size and shape of the structure, the ceramic-based composite material prefabricated body of a certain structure is built. The structure integrated model is high in model accuracy and capable of accurately reflecting all components of the material, macroscopic andmicroscopic structure parameters are given at the same time, and convenience is brought to machining of preparation personnel.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Descriptor for video sequence and image retrieval system using said descriptor

InactiveCN1293782ARealize parameterizationTelevision system detailsImage analysisVideo retrievalViewpoints

Owner:KONINK PHILIPS ELECTRONICS NV

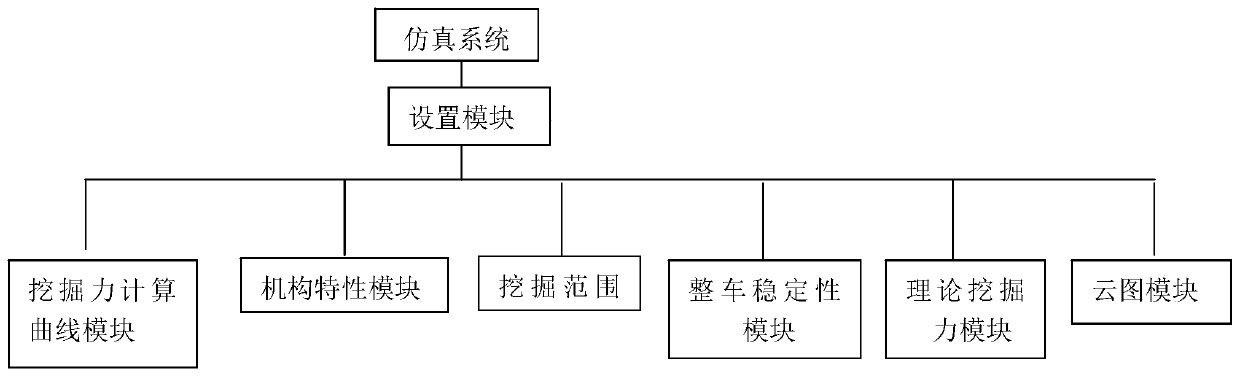

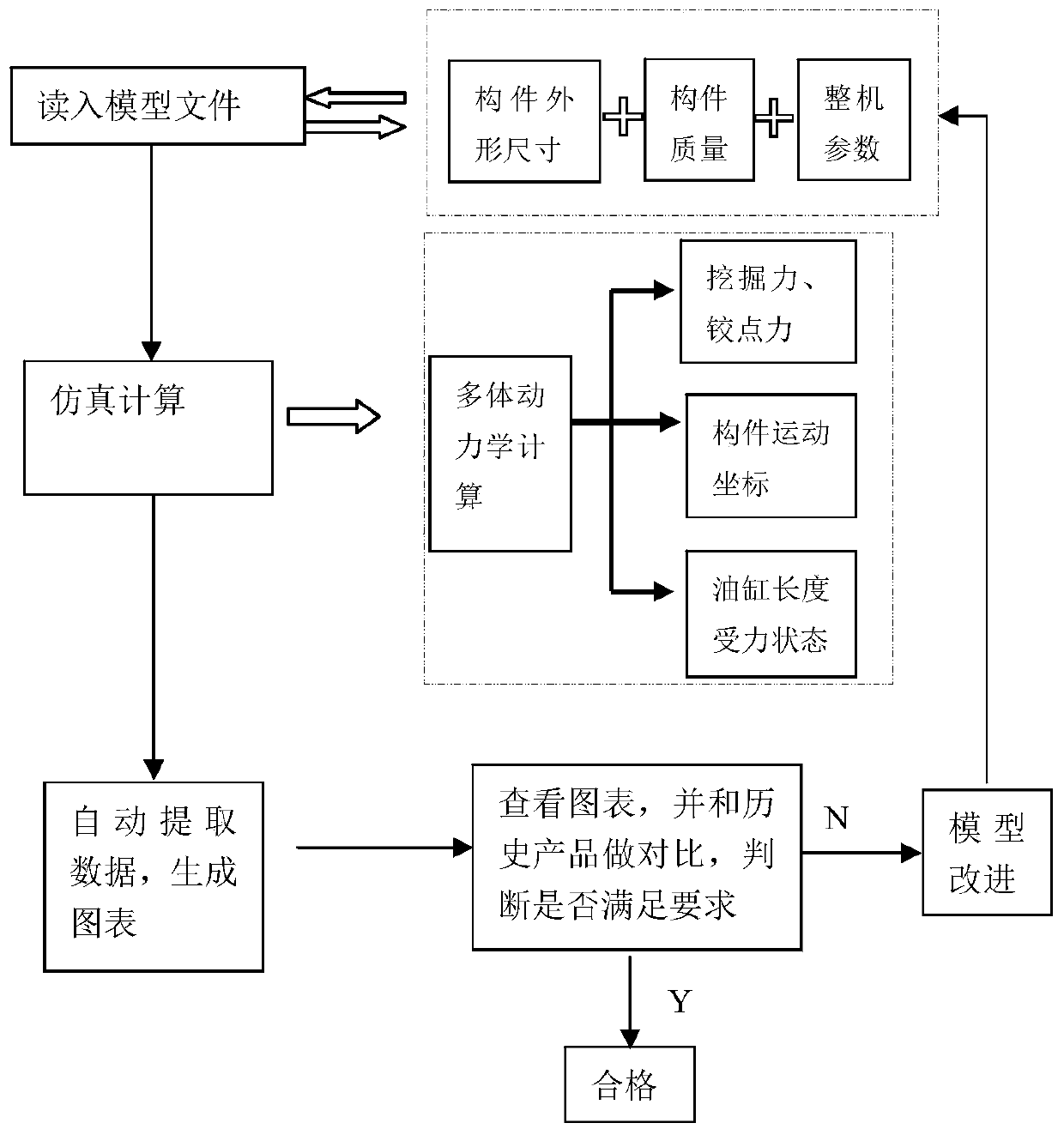

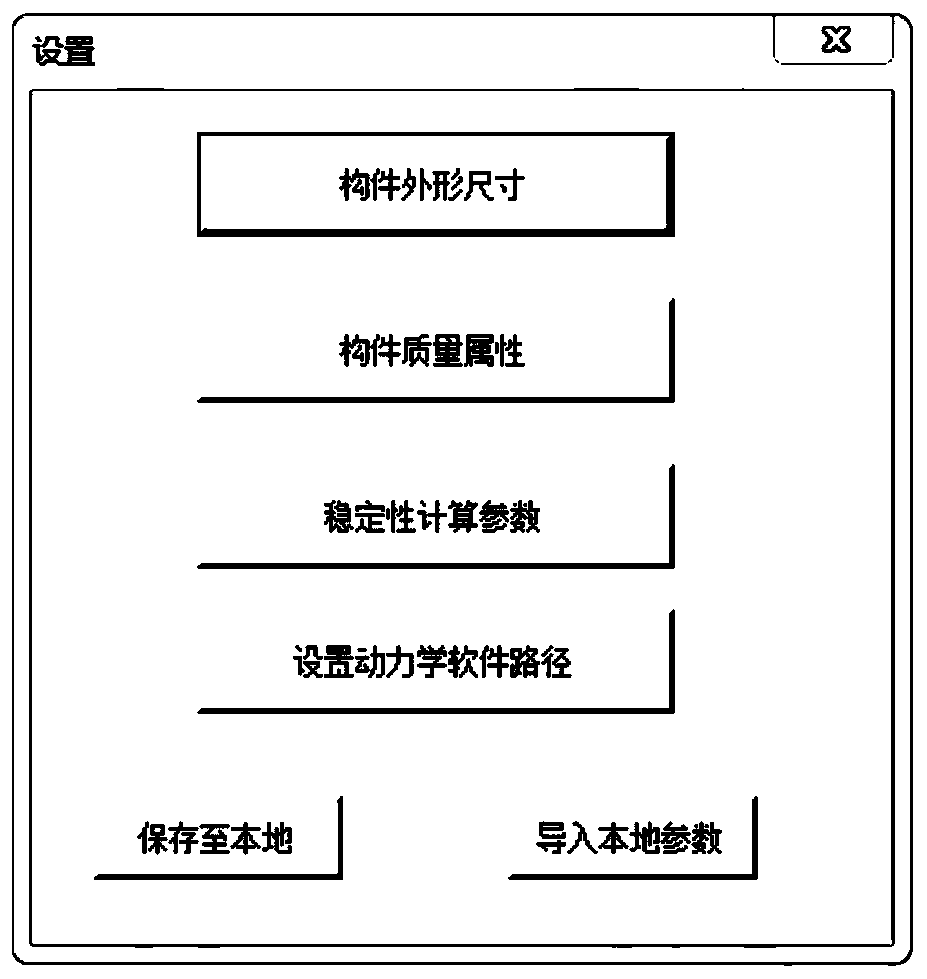

Excavator working device performance simulation calculation method based on VBA system

PendingCN111027153AImprove computing efficiencySave time and costGeometric CADSustainable transportationControl engineeringModularity

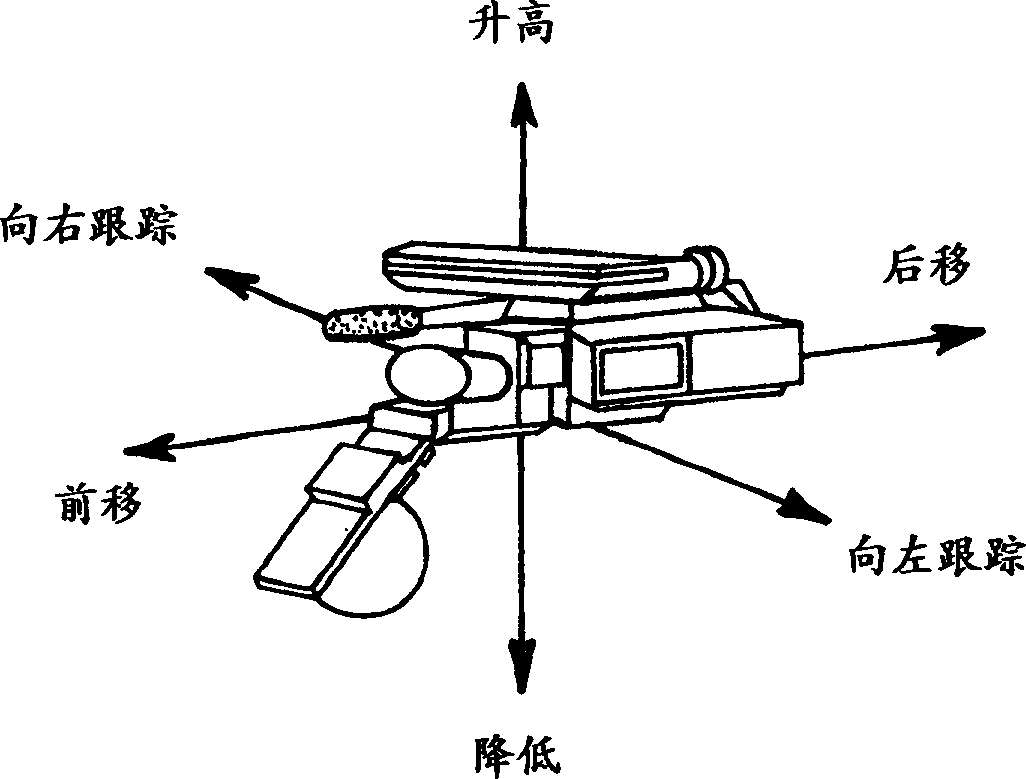

The invention provides an excavator working device performance simulation calculation method based on a VBA system. A simulation system based on VBA is included, the simulation system based on VBA isconnected with multi-body dynamics software, the simulation system based on VBA comprises a setting module, and the setting module is connected with an excavation force calculation curve module, a mechanism performance curve module, an excavation range module, a whole vehicle stability module, an oil cylinder theoretical excavation force module and a cloud picture module. According to the method,parameterization of the multi-body dynamic model of the working device, automation of the calculation and analysis process and modularization of basic performance calculation are achieved, the calculation efficiency is greatly improved, and the personnel and time cost is saved. Due to the fact that performance calculation of the working device is modularized and shares one input file, when one module is improved, only the input file needs to be changed, other modules do not need to be input again, other modules automatically update results, the simulation efficiency is improved in a modularized mode, and use is easy and fast.

Owner:QINGDAO LOVOL EXCAVATOR

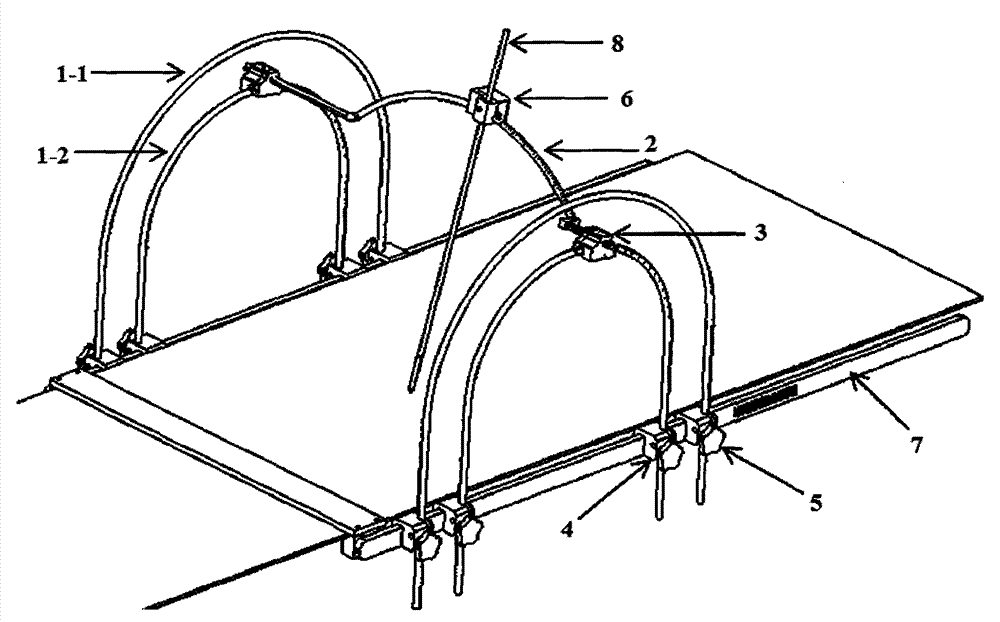

Closed reduction device for unstable pelvic fracture minimally invasive surgery

The invention discloses a closed reduction device for unstable pelvic fracture minimally invasive surgery. The closed reduction device for unstable pelvic fracture minimally invasive surgery comprises a first lateral outer frame, a second lateral outer frame, a connecting outer frame, guide rails, a guide rail sliding clamp, an outer frame sliding clamp, screws and a screw clamp, wherein the second lateral outer frame is smaller than the first lateral outer frame and arranged inside the first lateral outer frame, and the first lateral outer frame and the second lateral outer frame are fixed to the guide rails through the guide rail sliding clamp; the connecting outer frame is of the structure that the arc part is connected with transverse straight rod parts, the arc part and the transverse straight rod parts are not arranged on the same plane, and the transverse straight rod parts at the two ends of the arc part are coaxially arranged in the same plane; the connecting outer fame is connected with the second lateral outer frame through the outer frame sliding clamp; the screw clamp is used for clamping the screws and fixed on the connecting outer frame. The guide rails are arranged on two sides of an operation bed. The closed reduction device for unstable pelvic fracture minimally invasive surgery can recover an unstable pelvic fracture according to a specific route, a specific angle and specific parameters, the reduction effect is good, and pain of a patient is small.

Owner:张立海 +1

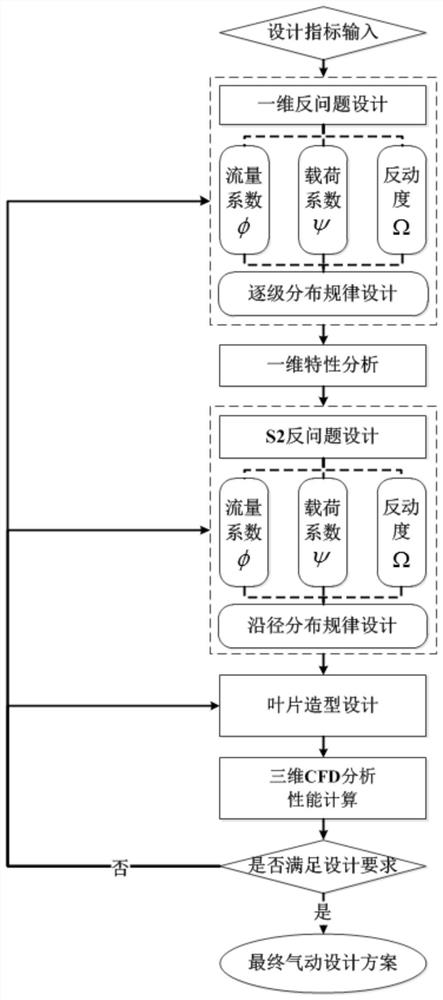

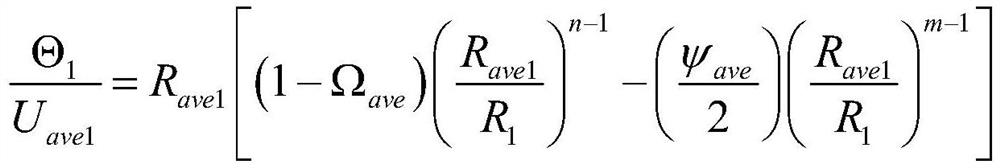

Multistage axial flow compressor aerodynamic design method based on key dimensionless load control parameters

ActiveCN112685851ASolve the space load matching problemImprove aerodynamic performanceGeometric CADDesign optimisation/simulationControl engineeringDegree of reaction

The invention aims to provide a multistage axial flow compressor aerodynamic design method based on key dimensionless load control parameters, which comprises the following steps of: repeatedly iterating links such as one-dimensional inverse problem design and characteristic analysis, S2 inverse problem design, blade modeling design, three-dimensional CFD analysis and the like; and obtaining a multi-stage axial flow compressor aerodynamic design scheme meeting design index requirements. Customized design of the internal load of the multi-stage axial flow compressor is achieved through three dimensionless parameters including the flow coefficient, the load coefficient and the reactivity, and the problem of space load matching between design points and low working conditions in pneumatic design of the multi-stage axial flow compressor is effectively solved; and the pneumatic design of the multistage axial flow compressor achieves the parameterization and refinement degree, the design precision is improved, and the design period is shortened. Meanwhile, the method is not limited to a multi-stage axial flow compressor of a gas turbine, but also suitable for the pneumatic design process of various industrial axial flow compressors and aero-engine axial flow compressors / fans.

Owner:中国船舶重工集团公司第七0三研究所

Computerized three-dimensional demonstration method for special case type structures

InactiveCN1702662AEasy to implementImprove work efficiencySpecial data processing applicationsSoftwareState of art

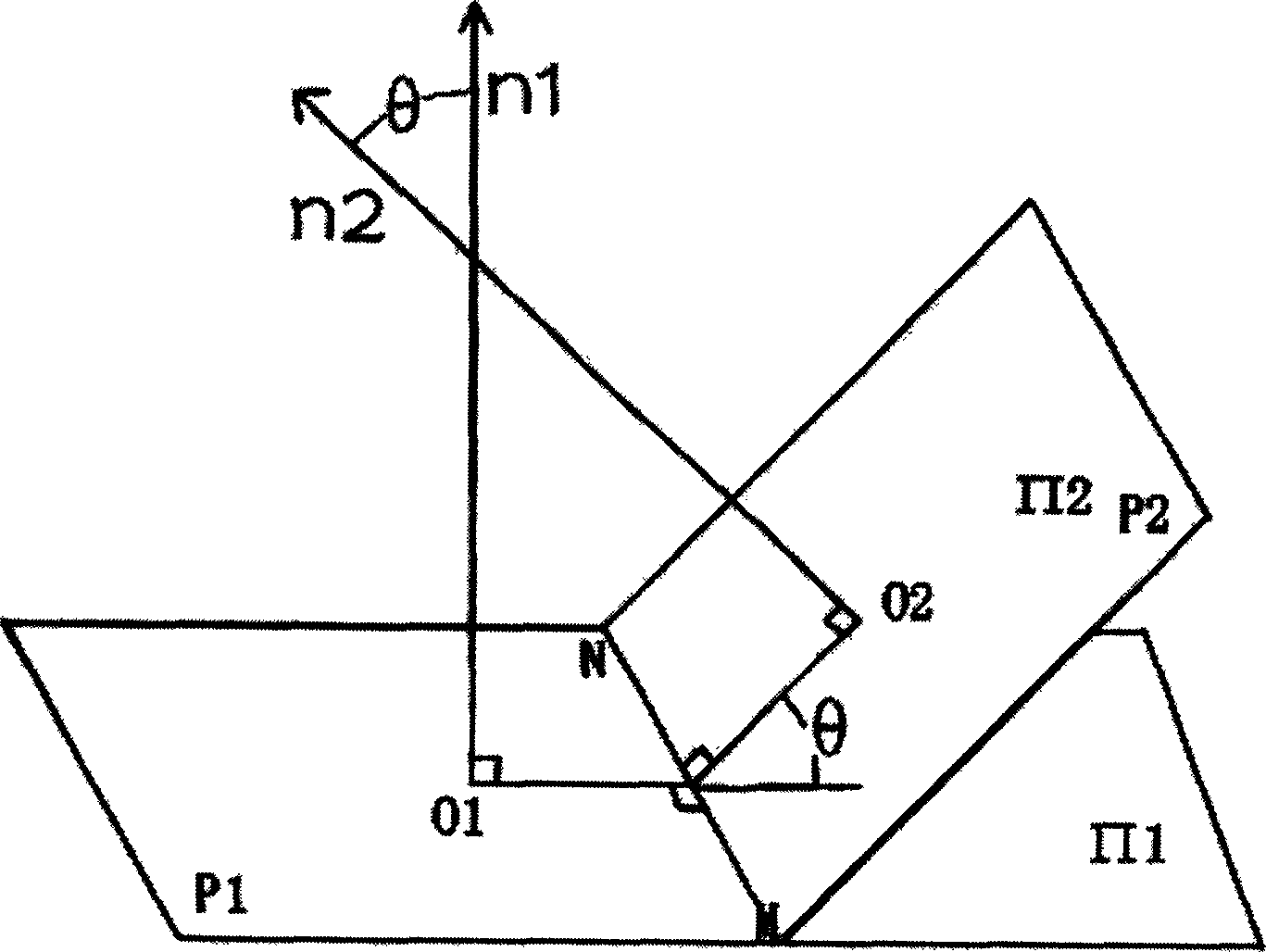

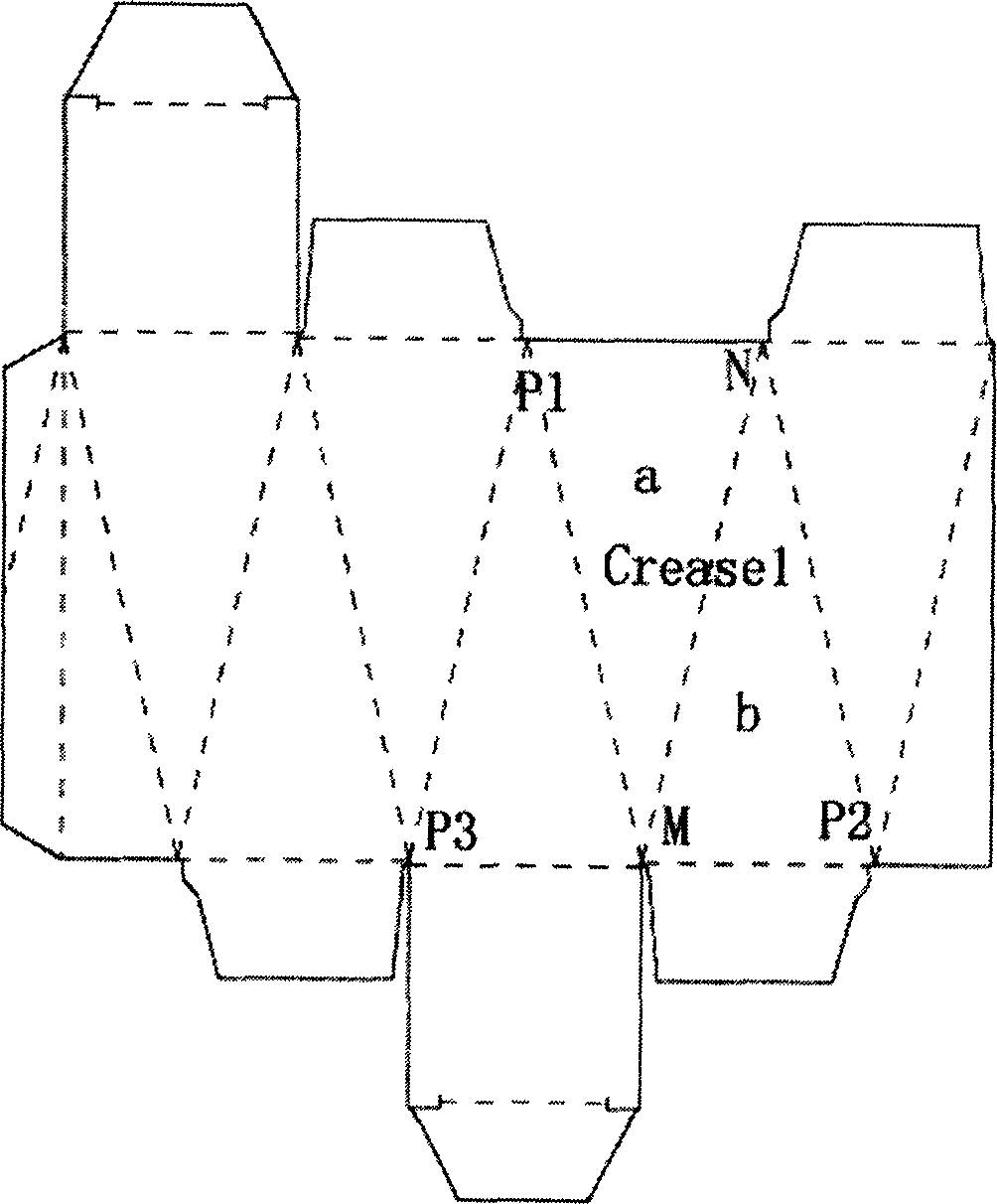

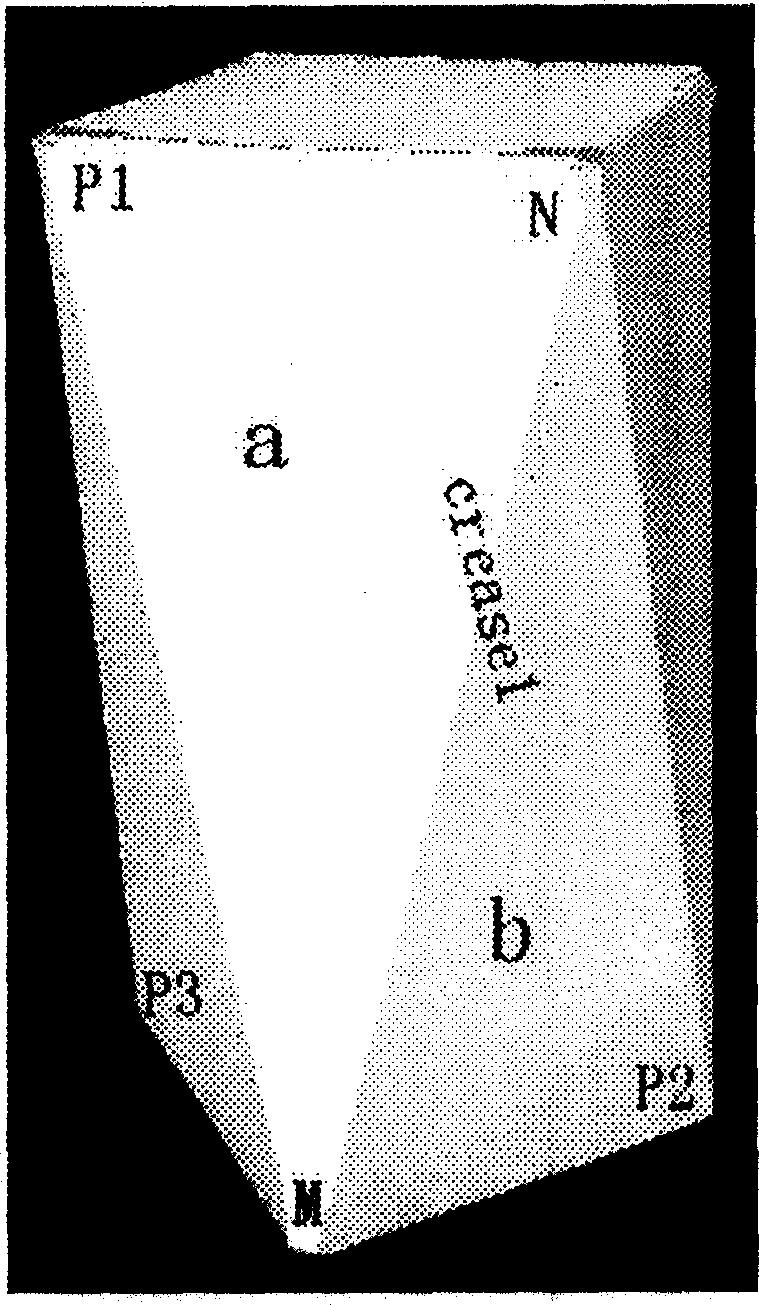

This invention relates to a computer three-dimensional demonstration method with a special case type, which belongs to the graph design field of case type structure in casing CAD. This invention relates to a method for building a relationship between folding angle and packing case dimension, thereby it realize the parameterized folding angle. Using this method can resolve the veracity problem on folding line and folding angle when demonstrating three-dimensional molding of special case type structure, and it can ensure the correct molding, and this invention can combine the automatic computing on folding angle and the handwork adjustment together to get the real-time mutual effect.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

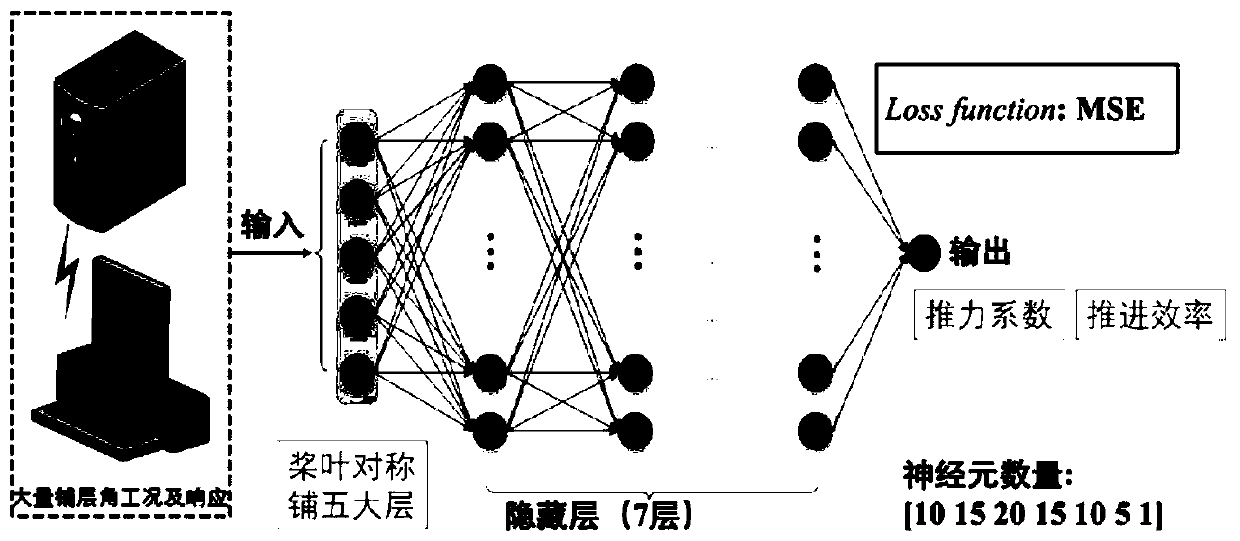

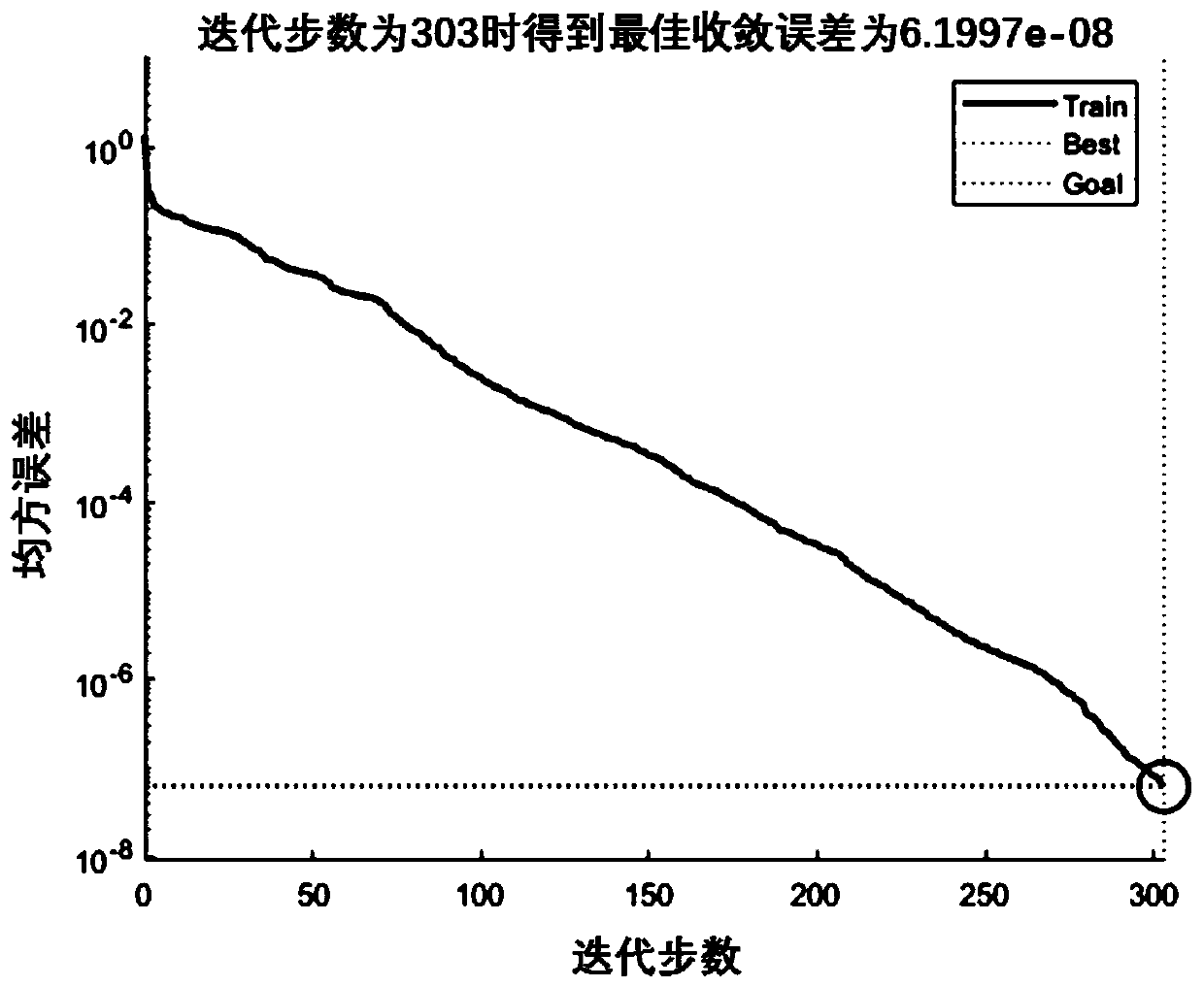

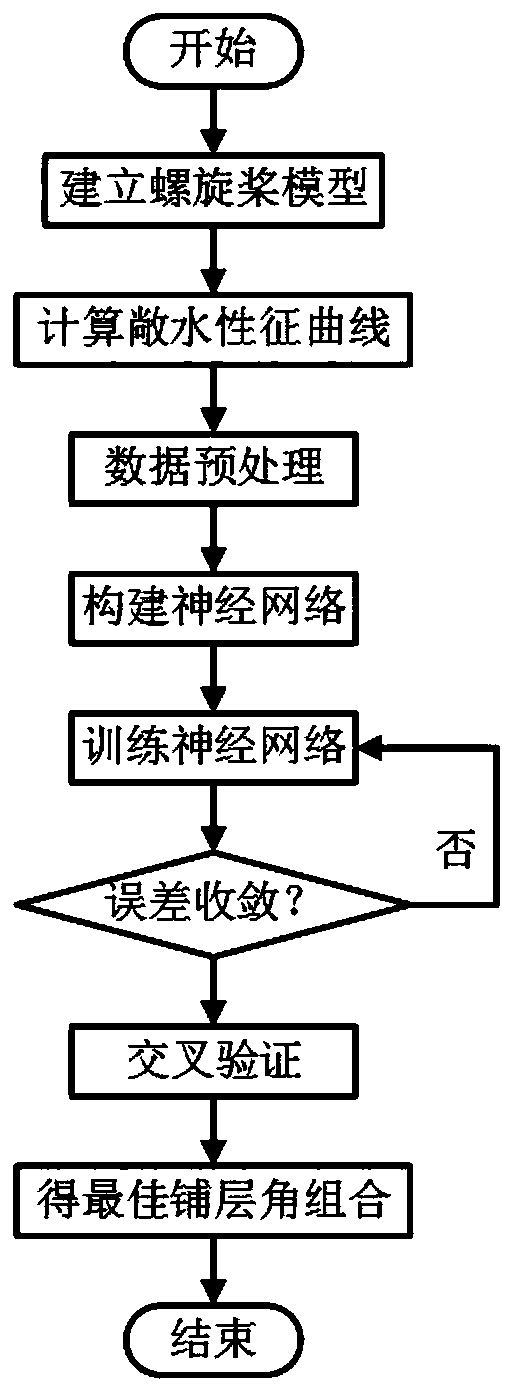

Composite material propeller layering angle optimization method based on neural network

ActiveCN111444643APly angle optimization achievedSmall amount of calculationGeometric CADGenetic modelsElement modelAlgorithm

The invention relates to a composite material propeller layering angle optimization method based on a neural network, and belongs to the technical field of turbomachinery simulation. The method comprises the following steps: establishing a composite propeller finite element model, and performing bidirectional fluid-solid coupling calculation on the composite propeller finite element model and a composite propeller computational fluid mechanics model to obtain a corresponding open-water characteristic curve; adopting an orthogonal test design method to preprocess the layering angle combinationand the corresponding hydrodynamic performance data; constructing a BP neural network with high nonlinear fitting based on numerical calculation software, training the constructed neural network by adopting a gradient descent algorithm, and finally obtaining the BP neural network with a mapping rule between the composite material propeller layering angle and the propulsion efficiency; and according to the trained BP neural network, carrying out optimization prediction on the combination situation of all the layering angles, and analyzing the obtained efficiency data to obtain the maximum network prediction value and the corresponding layering angle combination, that is, optimization of the lay-up angles of the composite propeller is realized based on the neural network.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

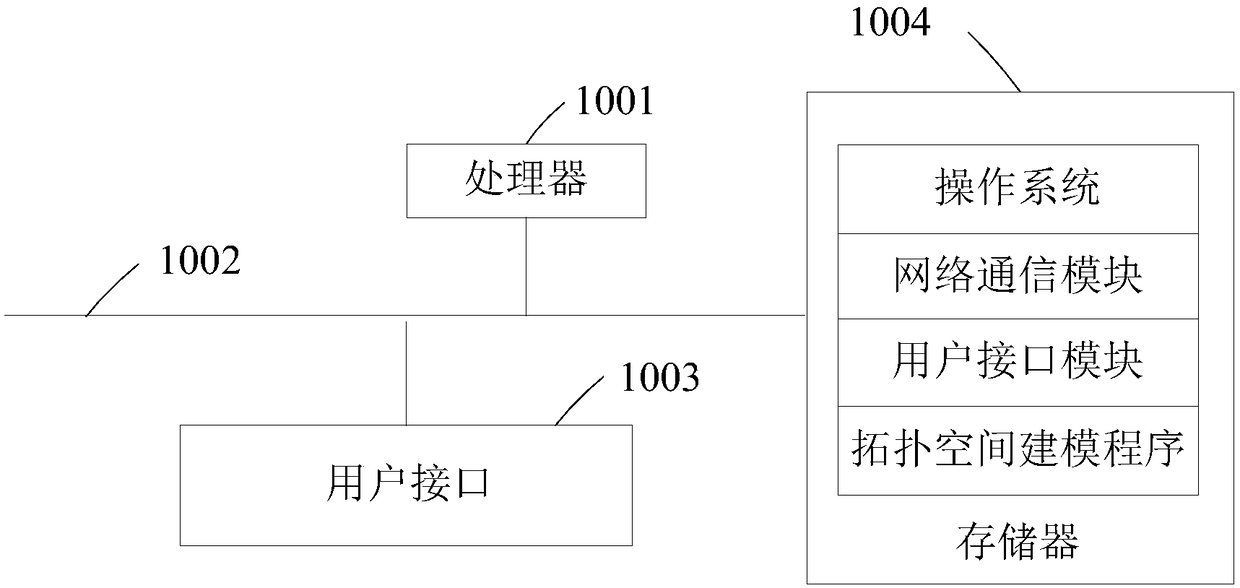

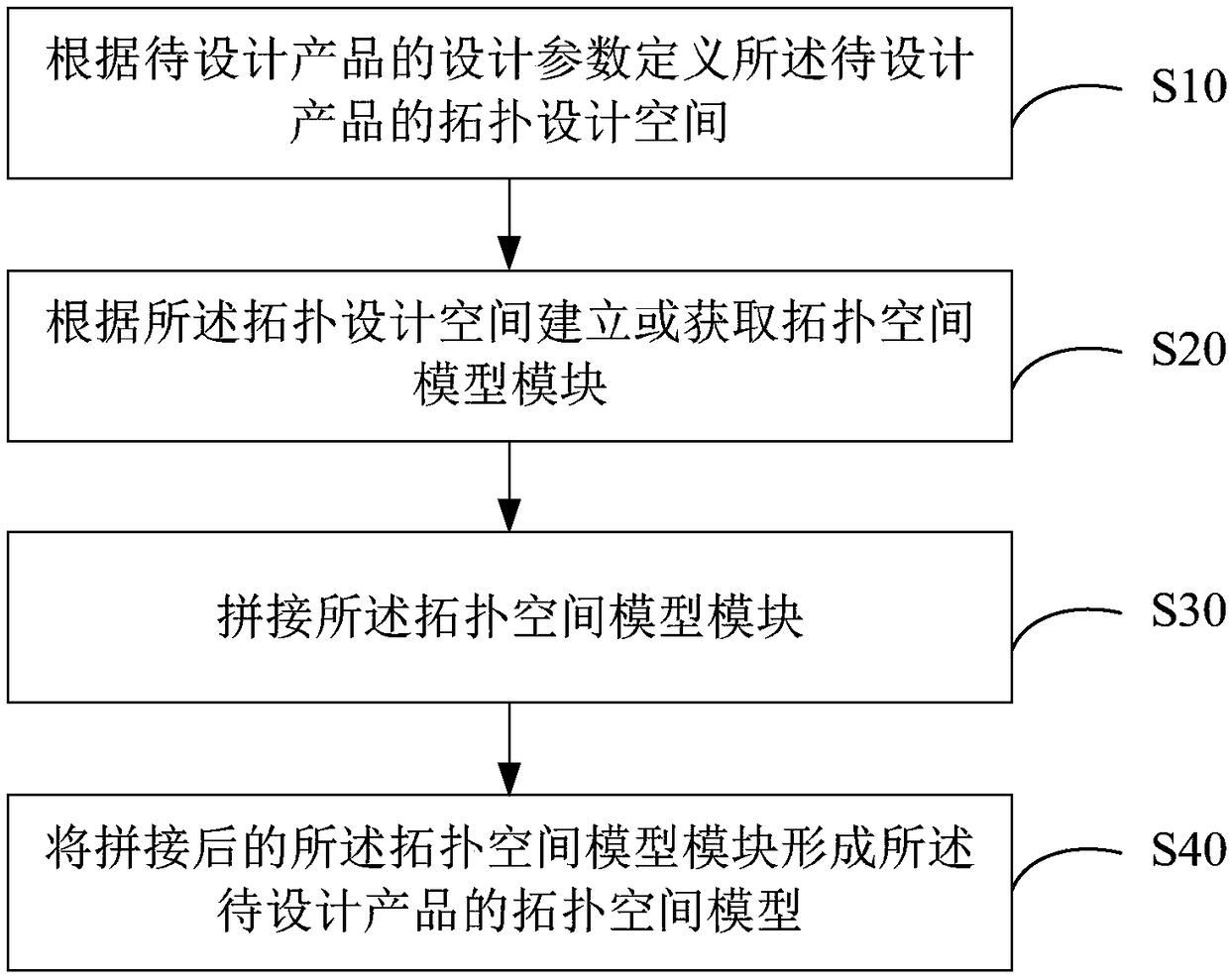

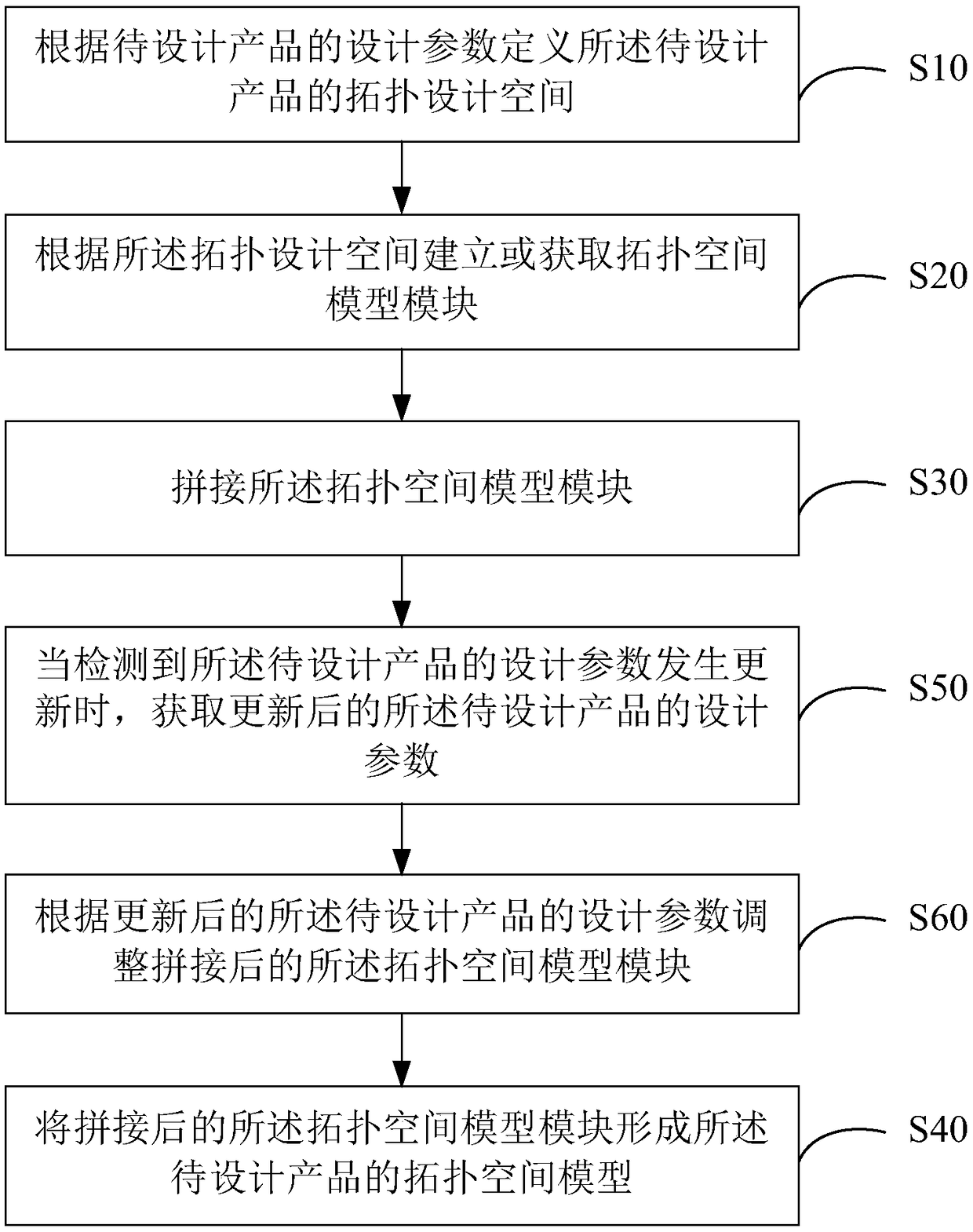

Topology space modeling method and device and computer-readable storage medium

InactiveCN108829953AFast updateAchieve modularityDesign optimisation/simulationSpecial data processing applicationsModularitySpace model

The invention discloses a topology space modeling method. The topology space modeling method includes the following steps: defining topology design space of a to-be-designed product according to design parameters of the to-be-designed product; establishing or acquiring topology space model modules according to the topology design space; splicing the topology space model modules; and using the spliced topology space model modules to form a topology space model of the to-be-designed product. The invention also discloses a topology space modeling device and a computer-readable storage medium. According to the method, the designed product is divided into multiple blocks for respectively establishing or acquiring the stored topology space model modules, then all the topology space model modulesare spliced into the topology space model, modularization and parameterization of topology space modeling are realized, the model modules can be reused many times, modeling difficulty is reduced, establishment steps of the topology space model modules are optimized, model updating speed in topology space modeling is increased, and modeling efficiency is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

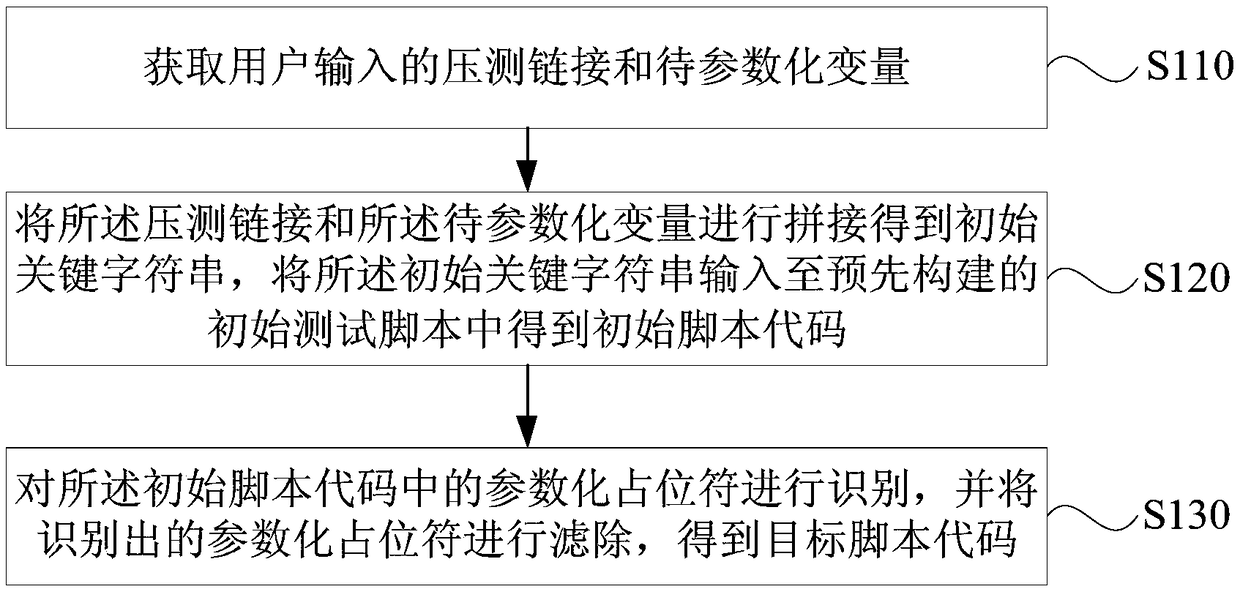

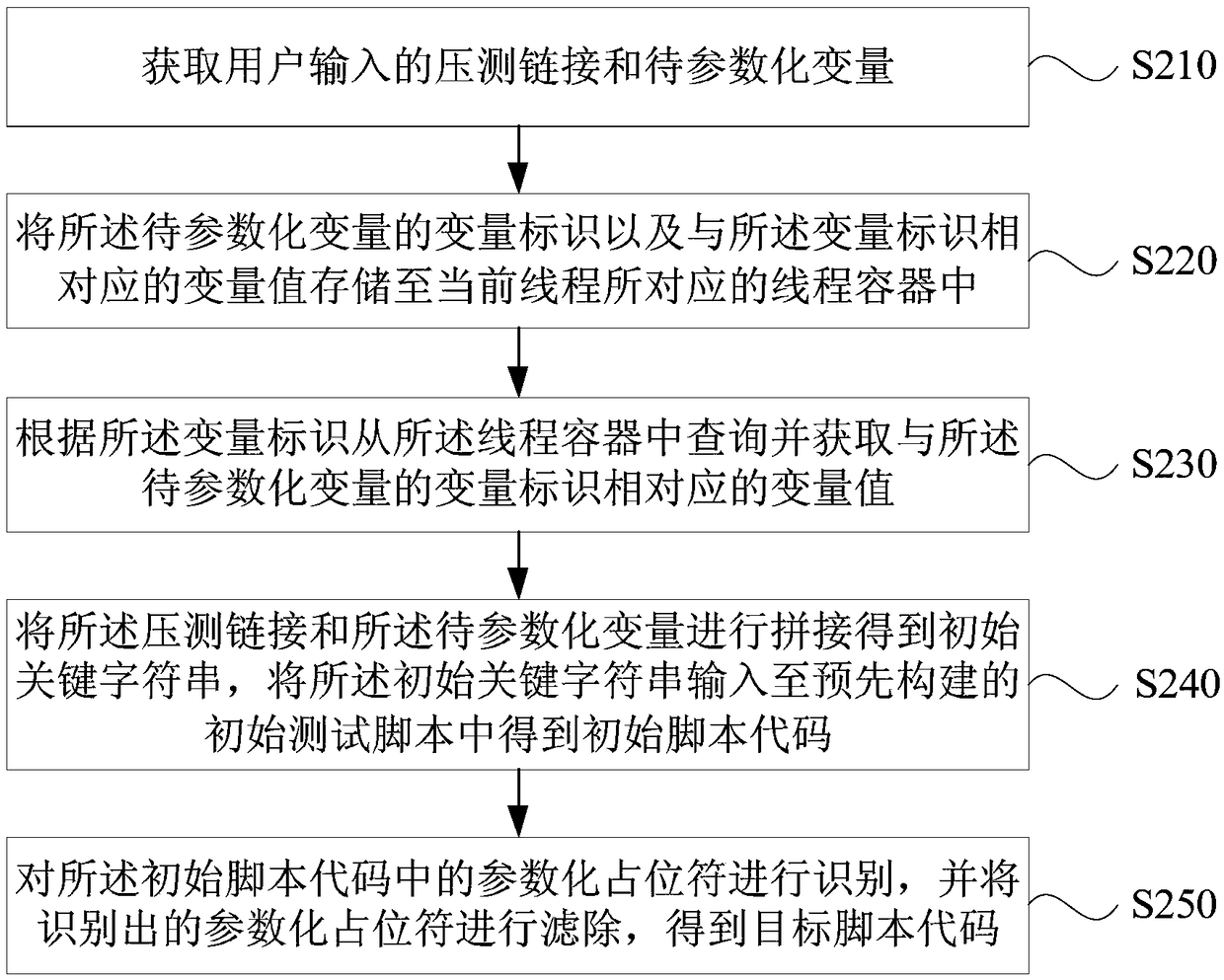

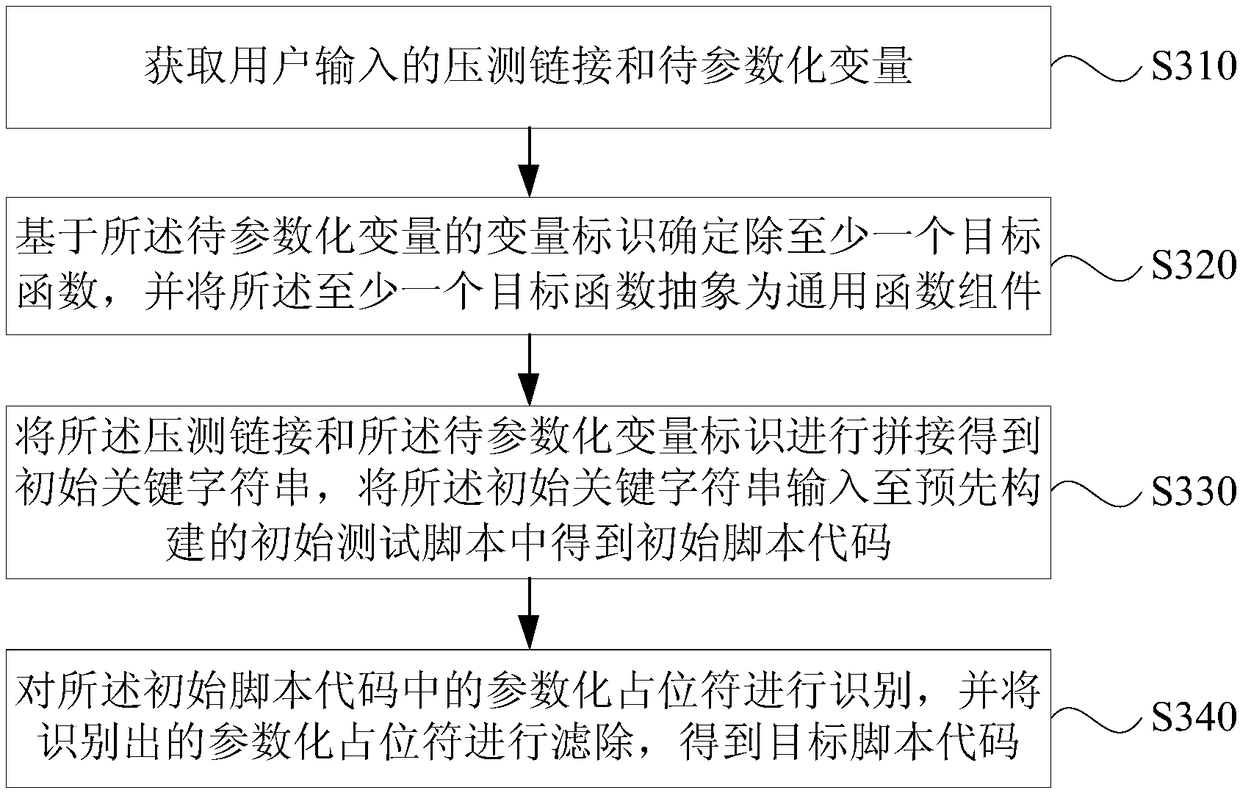

Test method, device, apparatus, and storage medium

ActiveCN109359045ARealize parameterizationLower the bar for testingSoftware testing/debuggingTest scriptSoftware engineering

The embodiment of the invention discloses a test method, device and apparatus and a storage medium. The method comprises the following steps: obtaining a pressure test link input by a user and a variable to be parameterized; splicing the pressure test link and the variable to be parameterized to obtain an initial key string, and inputting the initial key string into a pre-constructed initial testscript to obtain an initial script code; The parameterized placeholder in the initial script code is identified, and the identified parameterized placeholder is filtered to obtain the target script code. By adopting the technical proposal, the script is parameterized, the script code can be tested without manual modification of the tester, the test threshold of the tester is reduced, and the testdifficulty is reduced; At the same time, by filtering the parameterized placeholders in the process of script code generation, the code running time is reduced and the test cycle is shortened.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

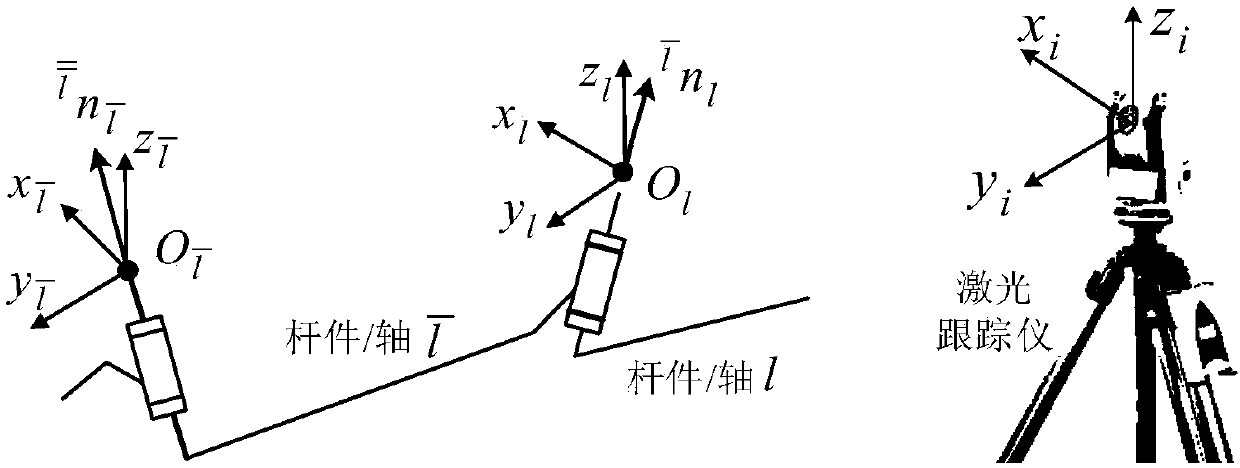

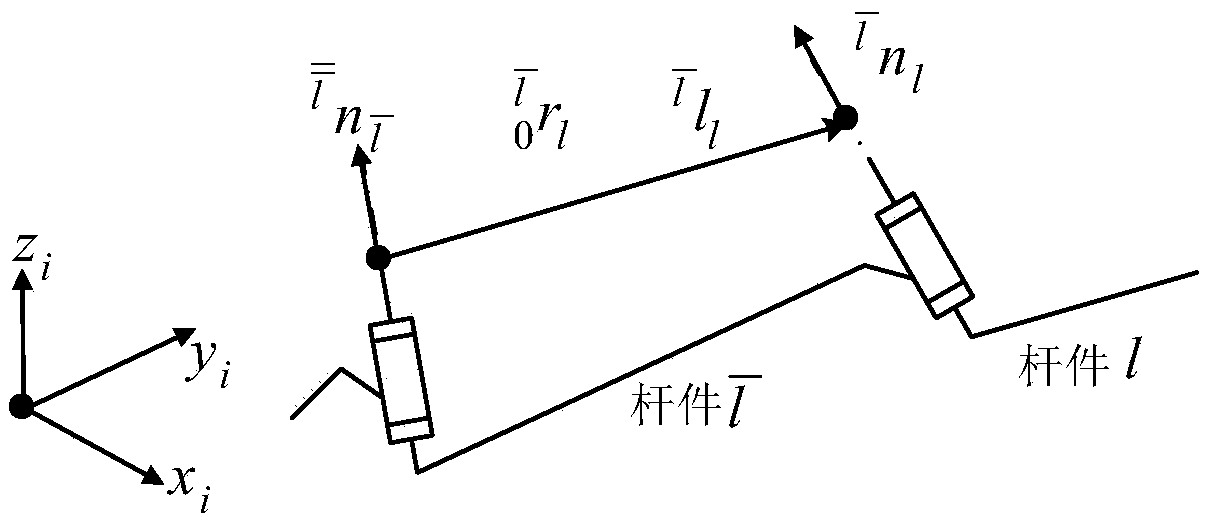

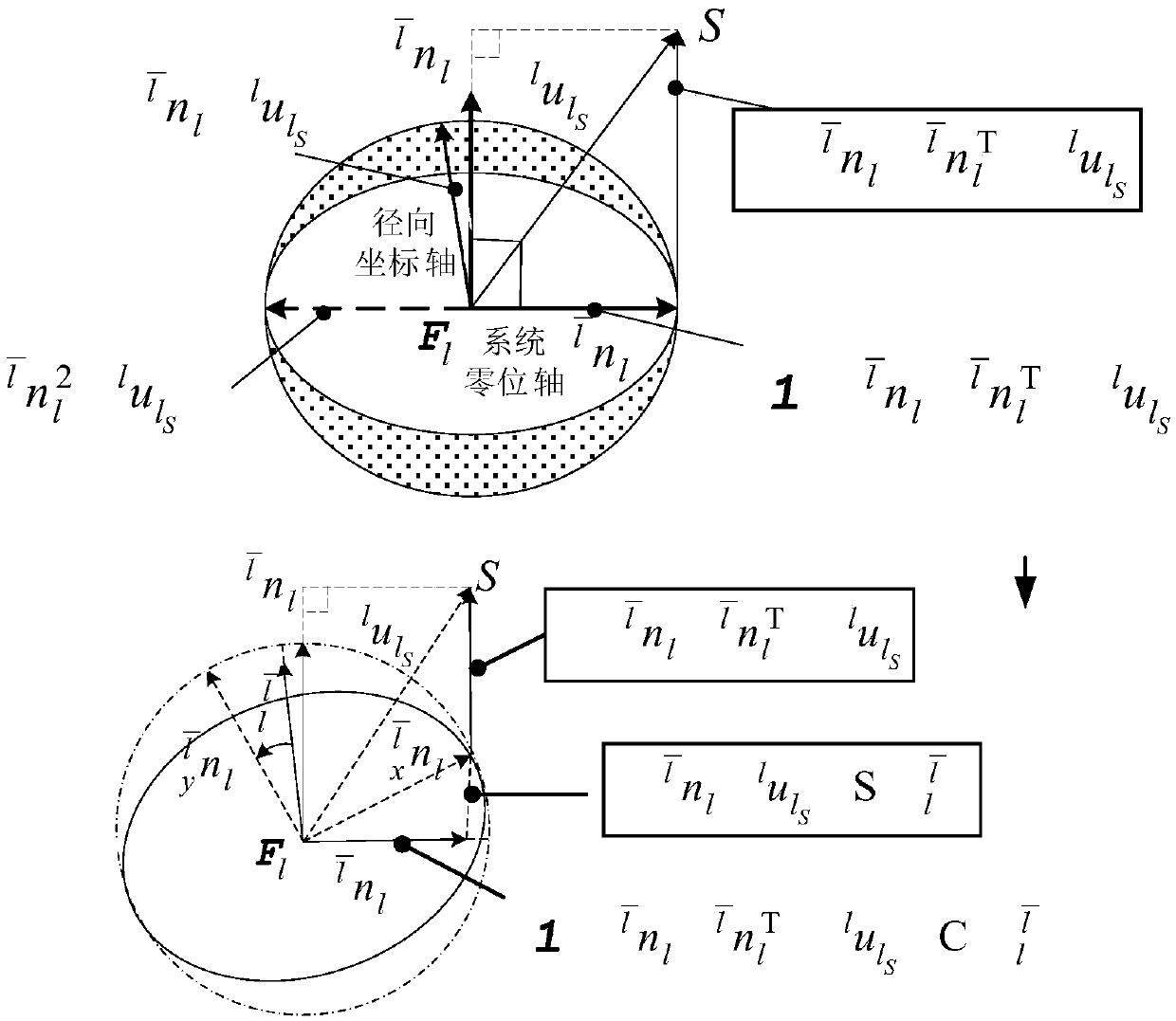

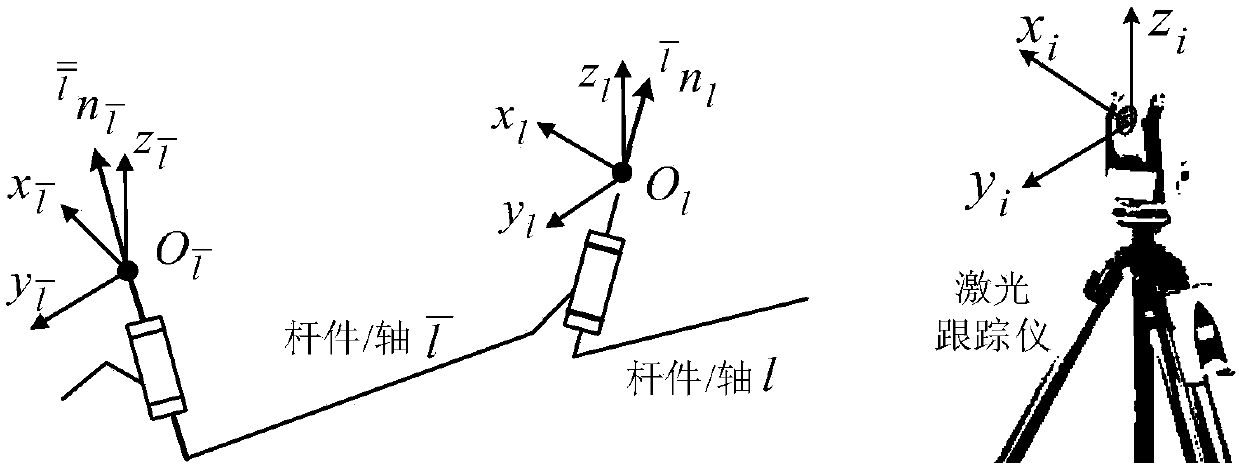

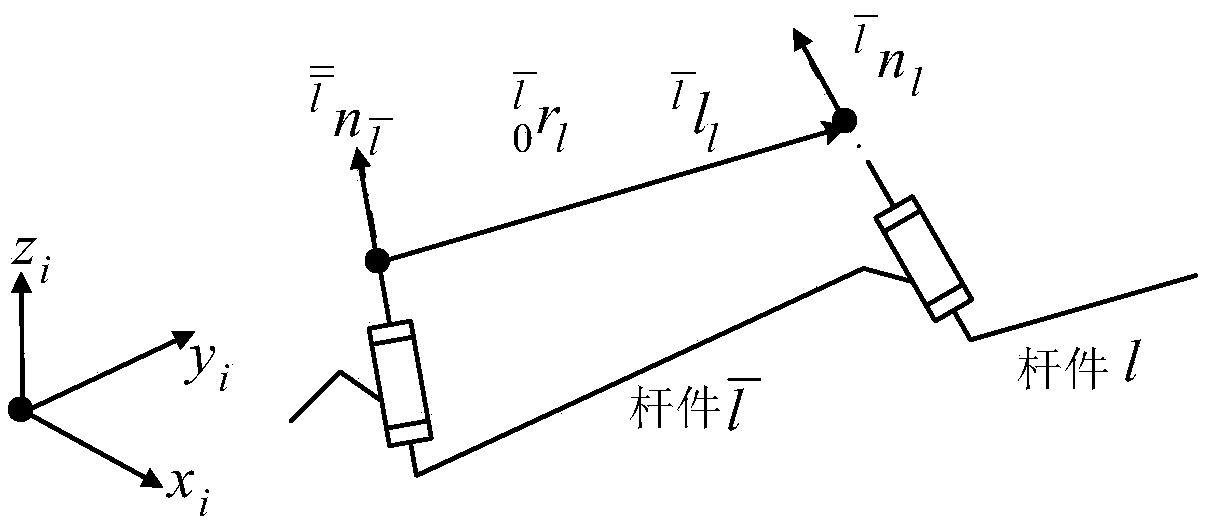

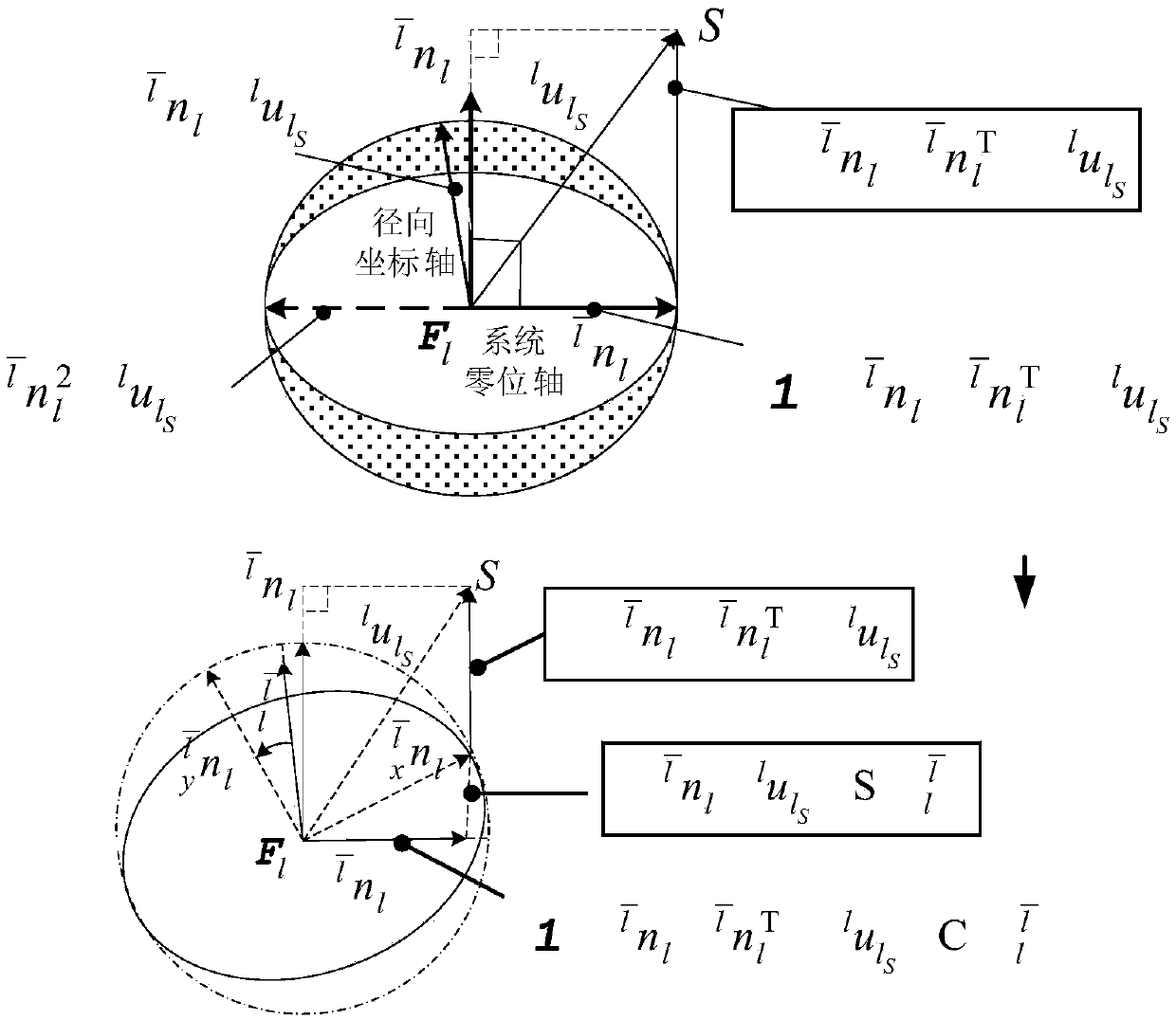

Inverse modeling and resolving method of universal 6R mechanical arm based on shaft invariant

ActiveCN109015641AGuaranteed reliabilityGuaranteed mechanical propertiesProgramme-controlled manipulatorQuaternionEngineering

The invention discloses an inverse modeling and resolving method of a universal 6R mechanical arm based on shaft invariant. Six rotating shafts are arranged, pick-up points are located on an axis of asixth shaft, and the mechanical arm which is not coaxial with a fourth shaft and a fifth shaft is the universal 6R mechanical arm; a formal pose equation of the 6R mechanical arm adopts a Ju-Gibbs quaternion expression to be expressed, and alignment is completed through the front 5 shafts so as to eliminate joint variables of the fourth shaft and the fifth shaft; and the sixth shaft is controlledto be aligned with an expected position through the front 5 shafts and pointing aligning of the sixth shaft is controlled through the front 5 shafts, so that the sixth shaft can freely rotate or control the sixth shaft to meet the radial alignment. According to the method, the inverse modeling and resolving method of the universal 6R mechanical arm is broken through, and the requirement for precision operation of the mechanical arm can be met.

Owner:居鹤华

General inverse solution modeling and solving method of 7R manipulator based on axis invariant

ActiveCN109033688AGuaranteed reliabilityGuaranteed mechanical propertiesGeometric CADProgramme-controlled manipulatorPopulationRotational axis

The invention discloses an inverse solution modeling and calculation method of a universal 7R manipulator based on axis invariant. The manipulator is a universal 7R manipulator, which is provided withseven rotational axes, the picking point is located on the seventh axis, and the fifth axis and the sixth axis are not coaxial. The universal 7R manipulator aligns the seventh axis with the desired position and attitude through the first six axes, so that the seventh axis infinitely rotates or the seventh axis satisfies the radial alignment. The kinematics equation of 7R manipulator is derived bymeans of the population function, and the kinematics equation of 7R manipulator is solved by using the population function. Gibbs quaternion expression, the sixth axis takes the point which is a certain distance from the picking point as the nominal picking point, first calculates the inverse solution of the universal 6R manipulator, and then completes the kinematic planning and inverse solutioncalculation of the universal 7R manipulator by using the numerical iteration method, thus solving the problem that the inverse solution of the universal 7R manipulator cannot be calculated in the prior art.

Owner:居鹤华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com